KB Electronics KBVF-48 User Manual

Page 22

10 AC LINE FUSING

This drive does not contain AC line fuses. Most electrical codes require that each ungrounded conductor

contain circuit protection. Do not fuse neutral or ground connections. It is recommended to install a fuse

(Littelfuse 326, Buss ABC, or equivalent) or a circuit breaker in series with each ungrounded conductor. Do

not fuse motor leads. For the recommended fuse size, see Table 2, on page 11.

Wire the drive in accordance with the National Electrical Code requirements and other local codes that may

apply to the application.

11 DRIVE OPERATION

11.1 START-UP PROCEDURE – After the drive has been properly setup (jumpers and trimpots set to the

desired positions) and wiring completed, the startup procedure can begin. If the AC power has been

properly brought to the drive, the power (PWR) LED will be illuminated green. The status (ST) LED will

indicate drive status, as described in Section 11.2. To remove and install the Finger-Safe Cover, see

Section 5, on page 14.

11.2 FAULT RECOVERY – The drive monitors

four faults (Undervoltage, Overvoltage,

Short Circuit at the motor (phase-to-

phase), I

2

t). Table 5 describes how the

drive will automatically start (factory

setting) after the fault has cleared.

Application Note – In Manual Start

Mode, the drive must be manually

reset for any fault. Use the Manual

Start Switch, as described in Section

9.6, on page 20. Also see Section

12.2, on page 23.

11.3 RESTARTING THE DRIVE AFTER AN

I

2

t FAULT HAS CLEARED – The drive

can be restarted after an I

2

t Fault has

cleared by any of the following meth-

ods.

Note: If an I

2

t Fault occurs, the motor

may be overloaded. Check the motor

current with an AC RMS responding

ammeter. Also, the CL setting may be

set too low. See Section 13.7, on

pages 25 and 26.

1 Disconnect and reconnect the AC

power (approximately 15 seconds).

The “ST” LED must change from quick flashing red to flashing red/yellow.

2 Setting the Main Speed Potentiometer to zero (fully counterclockwise).

Note: In order to be able to reset the drive by setting the Main Speed Potentiometer to zero, it is

necessary to have the MIN Trimpot set to zero (fully counterclockwise).

3 Open and close the Enable switch or contact. See Section 9.8, on pages 20 and 21.

12 DIAGNOSTIC LEDS

The drive contains two diagnostic LEDs to display the drive’s operational status. See Figure 5, on page 13,

for the location of the “PWR” and “ST” LEDs.

22

Notes: 1. Slow Flash = 1 second on and 1 second off. Quick Flash = 0.25

second on and 0.25 second off. 2. In Manual Start Mode, when the Overload

is removed, before the I

2

t times out and trips the drive, the “ST” LED will

flash green. 3. In Manual Start Mode, when the Undervoltage or Overvoltage

condition is corrected, the “ST” LED will flash Red / Yellow / Green.

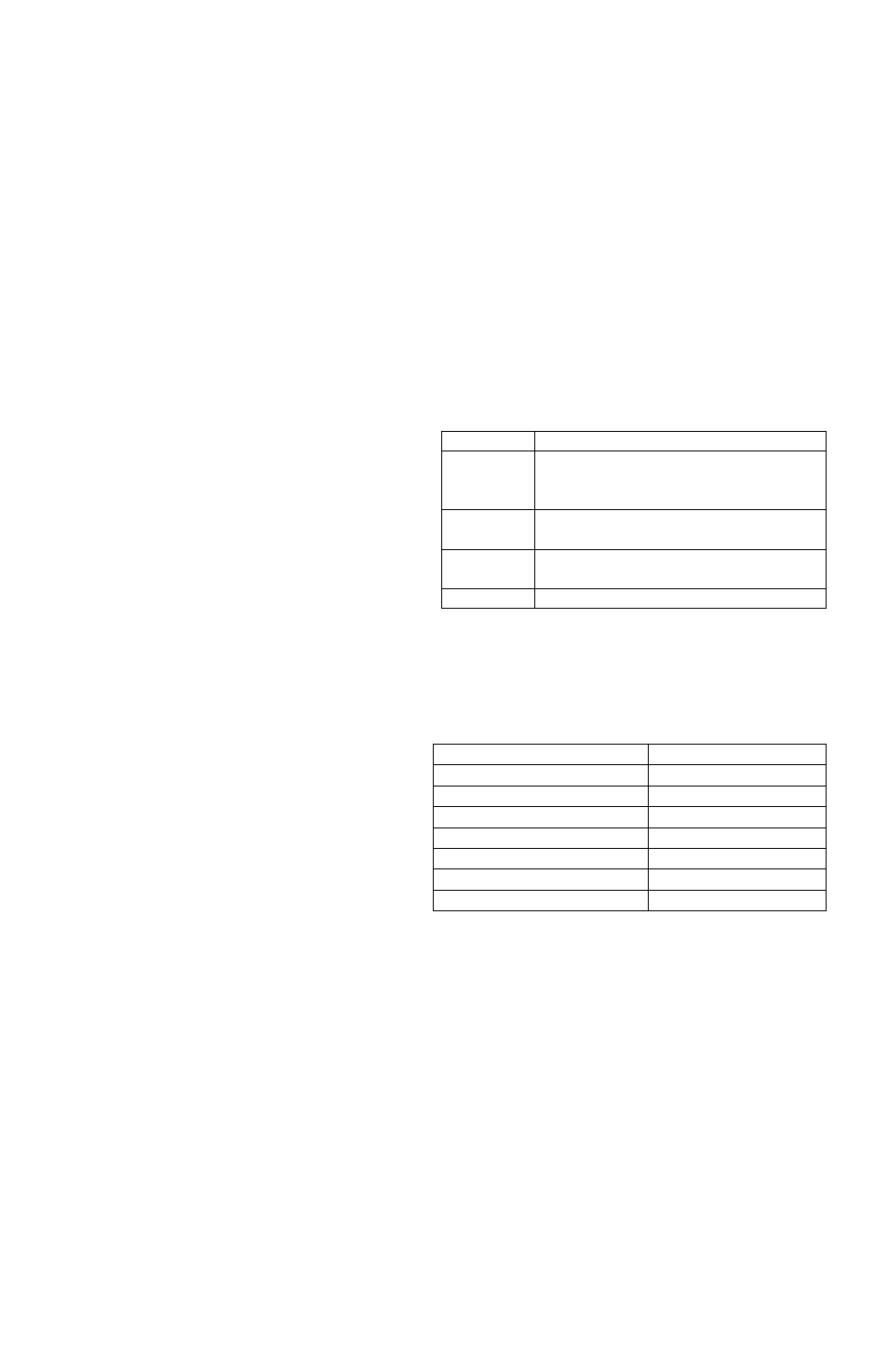

TABLE 5 – FAULT RECOVERY & RESETTING THE DRIVE*

Fault

Automatic Start Mode (Factory Setting)

Undervoltage

Drive will automatically start

after the bus voltage returns to the operational level

or when the drive is first turned on (power up).

Overvoltage

Drive will automatically start

after the bus voltage returns to the operational level.

Short Circuit

Drive will automatically start

after the short circuit is removed.

I

2

t

Drive must be manually restarted.

* The fault must be cleared before the drive can be reset.

TABLE 6 – DRIVE OPERATING CONDITION &

STATUS LED INDICATOR

Drive Operating Condition

Flash Rate

1

and LED Color

Normal Operation (Run)

Slow Flash Green

Overload (120% – 160% Full Load)

Steady Red

2

I

2

t (Drive Timed Out)

Quick Flash Red

Short Circuit

Slow Flash: Red

Undervoltage

Quick Flash Red / Yellow

3

Overvoltage

Slow Flash Red / Yellow

3

Stop

Steady Yellow