13 error messages – Hochiki FIRElink-400CM User Manual

Page 56

Page 56 of 58

FIRElink-400 Air Sampling System – Installation Manual

© 2010 Hochiki Europe (UK) Ltd

9-5-0-346/ISS4/OCT10

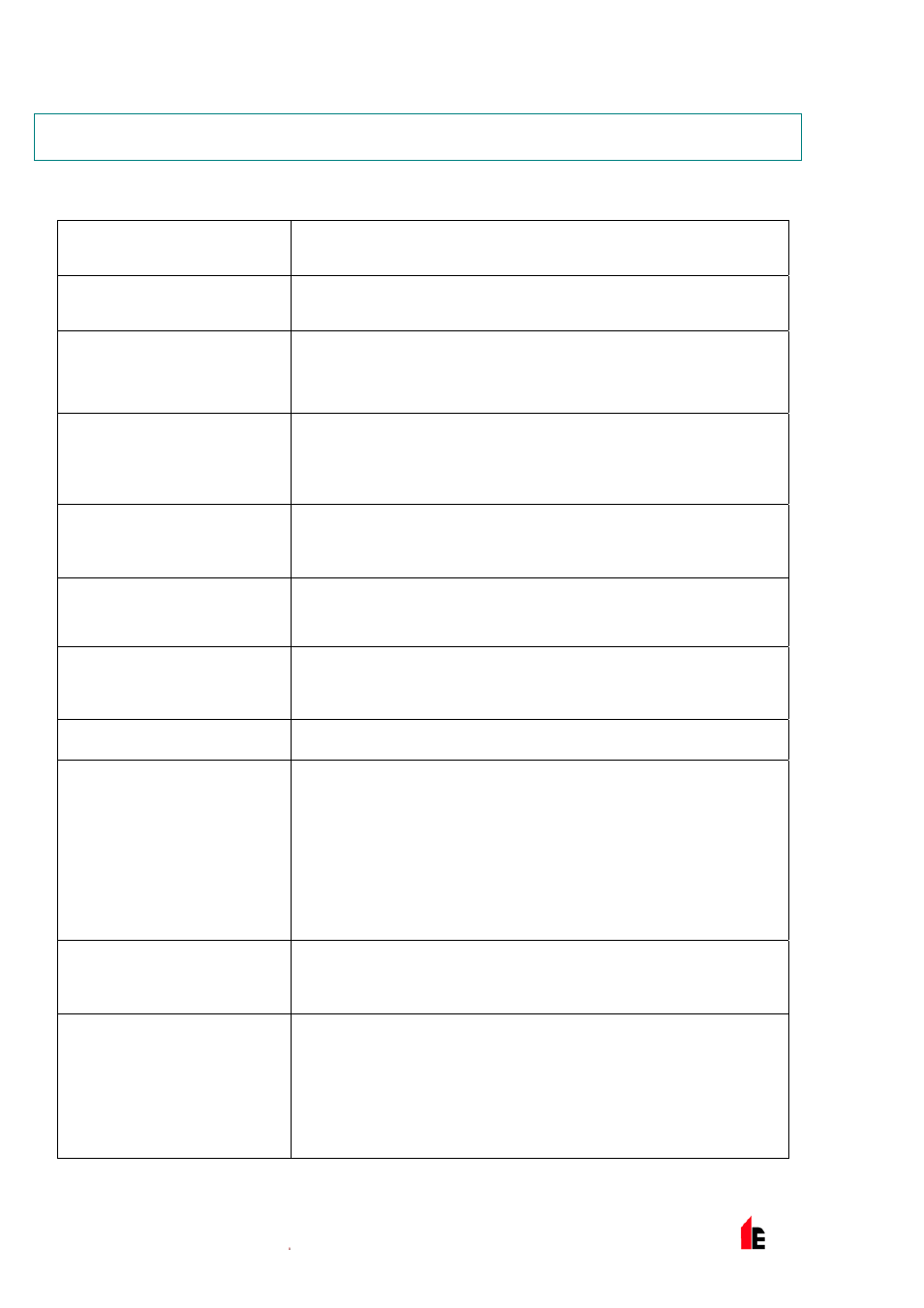

13 Error Messages

The FIRElink-400 text display can provide a wide range of information about the detector. A list of error

messages follows with a brief explanation of their meanings.

Separator renew

The dust separator requires replacement. See section 11

“Maintenance” on page 52.

Separator change

The dust separator is missing or improperly fitted. See section 11

“Maintenance” on page 52.

Bad value

Bad time

Bad date

A value has been input into a function, which is outside the parameter

range for that value. Take note of the range of values allowed (in

brackets) and try again.

Bad detector :

A detector address has been entered which is either outside the

allowed range or which is not present on the loop. This may also

happen if the user has entered address 000 (command module) for a

function which it does not support (for example, alarm factor).

No response

The Command Module has unsuccessfully attempted to read a

function value from a connected unit. Check that the unit connected

supports this function.

001

W

x

X

002

Loop break

There is a break in the communications loop between the detector

addresses specified. Check the wiring.

Comms fault

The Command Module has polled a detector and no response has

been received after the specified poll timeout value. See section

185619544.01.1.1 “Poll Timeout (Numeric - CM only)” on page 24

Bad access code

An incorrect access code has been entered. Enter the correct code.

Battery fault

This indicates either that the standby battery has discharged to a

predetermined level or that no standby battery is fitted. In the former

case, the battery should be replaced and recharged. In the latter

case, the battery check should be disabled (see section

185619544.01.1.1 “Battery Check Enable (Yes/No - Address 000-

127)” on page 21). It is important that the battery fault be acted upon

as soon as noticed, as excessive discharge may cause damage to

the battery. The battery fault condition comes on before the battery

reaches this portion of the discharge curve.

Watchdog reset

This indicates that there has been a power supply fault. If there are

frequent power outages it may be advisable to power the unit from a

UPS.

Detector fault

This indicates that there is a problem with the detector head. This

may be due to a number of causes. Refer to the chart readout if this

can be downloaded to a PC and note the detector signal level at the

time of the fault. When as much information as possible has been

determined about the conditions at the time of the error, please

contact the Hochiki Europe (UK) Limited Product Support Department

(see page 2).