Finish Thompson SP11/15 SERIES SELF-PRIMING User Manual

Page 13

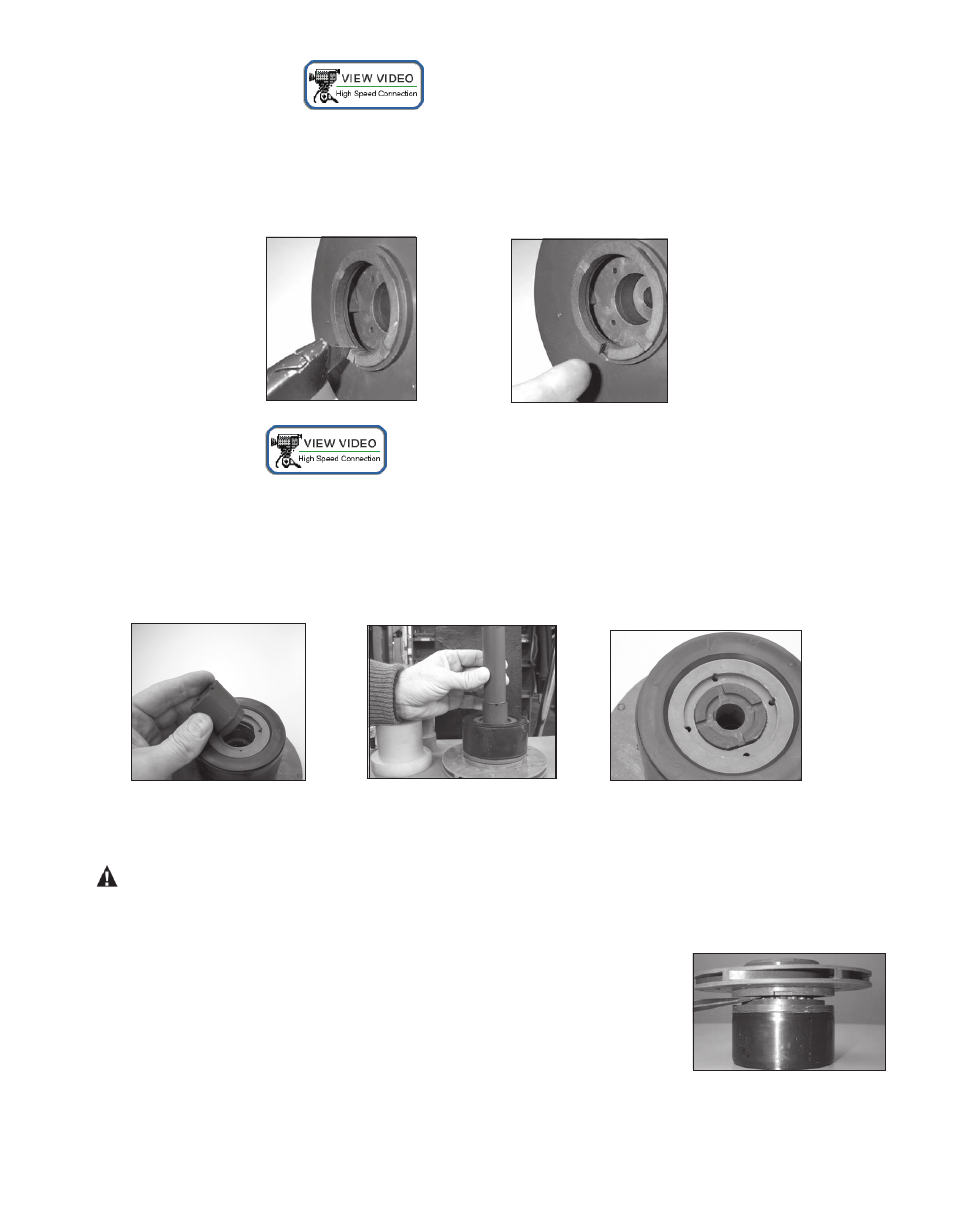

Thrust Ring Replacement

1. Thrust ring (item 7A) is held in-place with a snap fit with a ridge. Using a razor knife or side cutters, cut a notch

out of the thrust ring. Pull ring up and out of the holder. See figures 25 and 26.

2 To reinstall, align the two flats on the thrust ring with the flats in the bore of the impeller. Using a piece of wood

press into place using an arbor press until the thrust ring is completely seated in the impeller.

Bushing Replacement

1. To remove the bushing, place the impeller/inner drive assembly in an arbor press. Insert a 3/4” diameter plastic or

wood shaft through the eye of the impeller and press the bushing out.

2. To replace the bushing (item 8A), place the top of the impeller on an arbor press with the thrust ring face down.

Insert the front of the bushing (figure 27) into the center of the impeller/inner drive magnet assembly, aligning the

flat on the bushing with the flat in the bore of the inner drive magnet. Using a soft arbor, press into place until the

bushing reaches the shoulder molded into the inner drive (figures 28, 29).

Impeller Replacement

CAUTION: Do no damage the outer surface of the inner drive magnet during impeller replacement.

Using the two slots provided, insert a flat blade screwdriver into them and pry the impeller (items 7A, 7) up from the

body of the inner drive magnet (items 8, 8A). Once a gap has been established, work around the perimeter to evenly

increase the gap until the impeller can be removed. See figure 30.

To install a new impeller, place the inner drive magnet assembly face up (splines

facing up) on an arbor press. Align the spines in the impeller with the ones in the

bore on the inner drive magnet. Place a piece of wood over the top of the impel-

ler thrust ring. Using an arbor press, push down on the impeller until it is com-

pletely seated in the inner drive.

Figure 25

Figure 26

Figure 27

Figure 28

Figure 29

Figure 30

13