Finish Thompson AK / AV 4 & 5 SERIES User Manual

Finish Thompson Pumps

1

Assembly

PumPs with motors

1. No assembly required. simply unpack the pump and motor

and examine for any signs of shipping damage. if damage is

detected, save the packaging and notify the carrier immediately.

2. to install the pump into the system, follow the installation

instructions provided.

PumPs without motors

1. unpack the pump and any supplied accessories and examine

for damage. if damage is detected, save the packaging and

notify the carrier immediately.

2. Lay the motor on its side. install the slinger ring (item 2)

onto the motor shaft. After coating the motor shaft threads

with a thread lube, thread the pump shaft (item 8) onto the

motor shaft about 3 full turns. install the four set screws

(item 6) in the motor end of the pump shaft, but do not

tighten.

3. Gently place the motor on the fan cover so the pump shaft

points straight up. install the mounting plate (item 1) with

the four locating tabs (these are welded on one side of the

plate) facing the motor and locating on the raised motor face.

slide column assembly (item 7) over the pump shaft and at-

tach to the motor with the four mounting bolts, flat washers

and lock washers (items 5,3, 4) going through the column

flange and the mounting plate.

4. Lay the pump on its side and remove the fan cover from the

motor.

AK / AV 4 & 5 SERIES

Metallic Vertical Centrifugal Pumps

Installation and Maintenance Instructions

8. on AK/AV 4 models, spin the fan blade and visually check

to make sure all four impeller fins are not rubbing and are

straight in relationship to the back head section of the column

assembly. Gently adjust the fins if necessary.

9. install the impeller housing (item 16) (without the o-ring) and

hold in place with your hand. spin the fan blade while listen-

ing and feeling for impeller rubbing. Pump shaft adjustment

can be made if necessary.

10. replace the motor fan cover and gently place the pump on the

motor fan cover.

11. Clean the o-ring sealing area on the back head section of the

column assembly and the impeller housing. Lubricate the

o-ring (item 10) with a compatible lubricant.

12. install the impeller housing and v-clamp (item 11). impeller

housings with the discharge attached need to be inserted into

the hole in the mounting plate and visually aligned with the

column assembly. snug the nut on the v-clamp.

13. the alignment for the discharge can be adjusted by tapping

the impeller housing discharge left or right with a rubber mal-

let. Visually check that the discharge is parallel to the column

assembly and it goes through the mounting plate straight.

14. once the discharge alignment is correct the v-clamp nut can be

tightened.

15. insert a 1/2” socket into the suction and spin the impeller to

check clearances.

16. install the pump into the system following the installation

instructions provided.

InstAllAtIon

mouNtiNG:

1. Base plate must be securely fastened so that there is no vibration

when the pump is running.

2. Align the piping with the pump ports. Do not connect the piping

until it is aligned properly and supported independently. Do not

pull the piping in line with the pump or support the piping with

the pump.

3. A valve should be installed in the discharge line. During initial

operation of the pump, determine the power consumed. if

necessary, throttle back the flow until the pump draws the

rated horsepower of the motor.

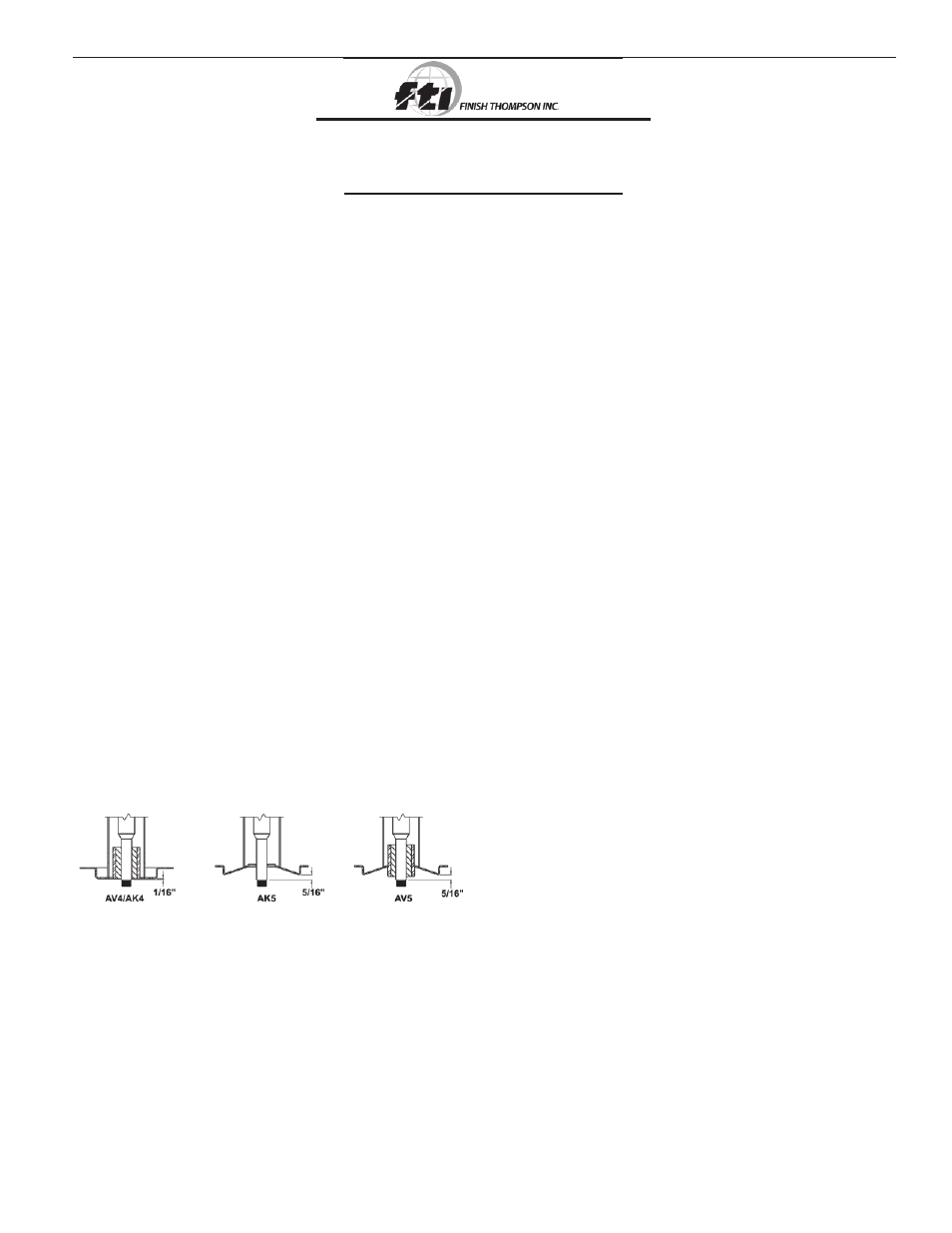

5. holding the motor fan, adjust the pump shaft by threading

clockwise or counterclockwise until the pump shaft shoulder

is set correctly (see figure 1).

6. tighten the setscrews in the pump shaft through the access

hole at the motor end of the column assembly.

7. After applying a thread lube, thread the impeller (item 12) on

until it bottoms out on the pump shaft shoulder. install the

5/16 bolt, washer and lock washer (items 15, 13, 14) in the

impeller end of the pump shaft.

Figure 1