Finish Thompson MSKC series User Manual

Finish Thompson Pumps

1

Caution: Do not operate/test the motor with the drive

magnet assembly exposed.

.040”

STRAIGHT

EDGE

DRIVE

MAGNE

T

ASSY.

MSKC SerieS Multi-Stage

Sealless Non-Metallic Centrifugal Pumps

installation and Maintenance instructions

ASSeMBLY

WaRninG: Magnetic field hazard. This pump contains

powerful, rare earth magnets. When the pump is disassembled

(not connected to a motor) and the magnets are exposed, these

magnets produce powerful magnetic fields. individuals with

cardiac pacemakers, implanted defibrillators, other electronic

medical devices, metallic prosthetic heart valves, internal wound

clips (from surgery), metallic prosthetic devices or sickle cell

anemia must not handle or be in the proximity of the magnets

contained inside the pump. Consult a health care provider for

specific recommendations before working with this pump.

Unpack Pump, Drive Magnet Assembly and Hardware Package

from carton and check for shipping damage.

PUMPS WiTH MOTOrS

Proceed to installation Section.

PUMPS WiTHOUT MOTOrS

(56C frame)

1. remove pump, drive magnet assembly and hardware package

from box.

Caution: Keep away from metallic particles, tools and

electronics.

Caution: Drive magnets MUST be free of metal chips.

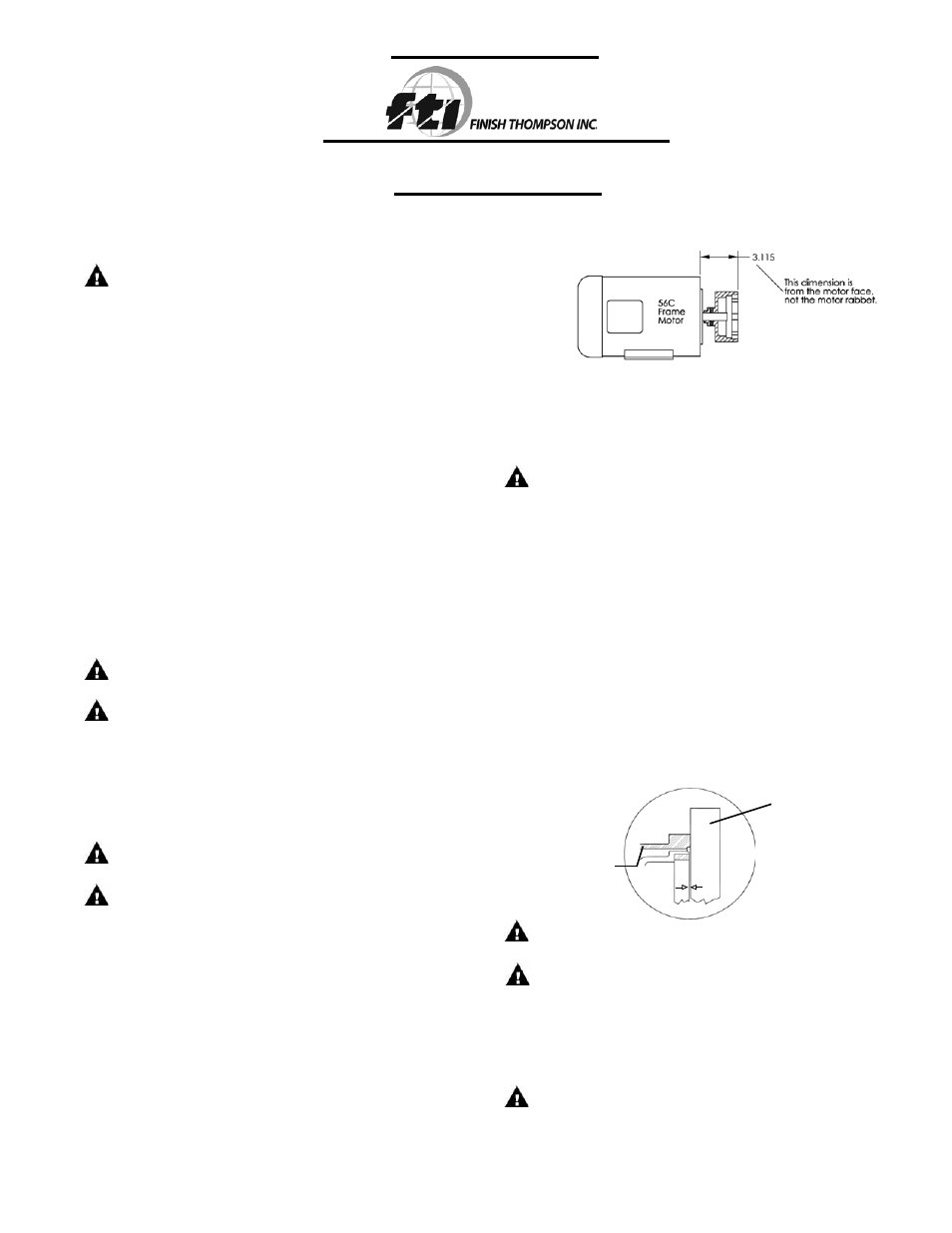

2. Slide drive magnet assembly (item 10) onto the motor shaft

until it is between 3.110” and 3.120” as measured from the

motor face to the top of the drive magnet assembly. See

Figure 1. Align cone point set screw (item 10B) with key slot

on the motor shaft and tighten both set screws with a 5/32”

Allen wrench to 140 in-lbs. (15.8 N-m).

Caution: Do not operate/test the motor with the drive

magnet assembly exposed.

WaRninG: Magnets are strong. To avoid damage and pinch-

ing fingers, tightly grasp pump assembly keeping finger tips

away from the area where the motor adapter and motor meet.

3. Carefully slide the pump assembly over the drive magnet

assembly. Orient the discharge port to either the 12 or 9

o’clock position. Make sure rabbet (step) on motor is fully

seated into the motor adapter (item 11). Align bolt holes in

motor adapter and motor. install (4) bolts and washers (items

14A,14B,14C) from hardware package.

4. Manually rotate pump assembly to ensure that the pump is

not binding or rubbing on the drive magnet assembly.

5. install the pump into the system according to installation

instructions.

Figure 1

Caution: Drive magnets MUST be free of metal chips.

note: Prior to start-up, double check both drive magnet set

screws to assure that they are firmly tightened. Failure to do so

could result in internal damage. rotate to assure clearance with

the motor adapter.

WARNING: Magnets are strong. To avoid damage and pinch-

ing fingers, tightly grasp pump assembly keeping finger tips away

from the area where the housing and motor adapter meet.

PUMPS WiTHOUT MOTOrS

(71/B14 & 80/B14 frame)

1. remove pump, drive magnet assembly and hardware package

from box.

Caution: Keep away from metallic particles, tools and

electronics.

2. remove screws and washers (items 12A, 12B & 12C) from

impeller housing (item 1) and remove wet end assembly from

motor adapter (item 11).

3. install motor adapter onto motor (labels at top) and secure

with motor bolts and washers (items 14A, 14B, 14C) from

hardware package.

4. Slide the drive magnet (item 10) onto the motor shaft so that

the cone point setscrew (item 10B) is aligned with the motor

shaft keyway. install the drive magnet so that it is recessed

1.016 mm (.040” +/- .005”) below the surface of the motor

adapter (see figure 2). Tighten both setscrews with a 5/32”

Allen wrench to 15.8 N-m (140 in-lbs.).

Figure 2