Finish Thompson VKC 11 SERIES User Manual

Assembly, Installation

11111

ASSEMBLY

WARNING: Magnetic field hazard. This pump contains powerful

rare earth magnets. When the pump is disassembled (not

connected to a motor) and the magnets are exposed, these

magnets produce powerful magnetic fields. Individuals with

cardiac pacemakers, implanted defibrillators, other electronic

medical devices, metallic prosthetic heart valves, internal wound

clips (from surgery),metallic prosthetic devices or sickle cell

anemia must not handle or be in the proximity of the magnets

cntained inside the pump. Consult a health care provider for

specific recommendations before working with this pump.

PUMPS WITH MOTORS

1.

No assembly required. Simply unpack the pump and motor

and examine for any signs of shipping damage. If damage is

detected, save the packaging and notify the carrier immediately.

2.

Ensure that lock rings are securely snapped in place and did

not loosen during shipment.

3.

Proceed to the “Installation” section of these instructions.

PUMPS WITHOUT MOTORS:

(56C/143-145TC FRAME)

1.

Unpack the pump and any supplied accessories and exam-

ine for damage. If damage is detected, save the packaging

and notify the carrier immediately.

2.

Create a hole if required for discharge piping in the optional

mounting plate (item 9) at desired location.

3.

Prepare to install the motor on the pump. Carefully place the

motor on the fan cover on a suitable, level work surface.

4.

Install key into motor shaft key slot. Align the keyway slot on

coupling half (item 8) and slide it into motor shaft. Set cou-

pling half flush with the end of the motor shaft and tighten

both set screws with 1/8” Allen wrench to 70 in-lbs. (7.9 N-m).

5.

Insert the coupling insert (item 9) into the coupling half on the

motor. Carefully slide motor adapter (item 8) end of the col-

umn assembly over the motor shaft until both coupling halves

are completely seated in the coupling insert. Make sure rabbet

(step) on the motor is firmly seated into motor adapter.

CAUTION: Pump assembly may be top heavy.

6.

Rotate the pump and mounting plate to the desired orienta-

tion. Align the holes in the mounting plate and the motor

adapter with the holes in the motor face. Secure the mount-

ing plate and motor adapter to the motor using (4) washers,

lock washers and 3/8" bolts (items 5,6,7) from the hardware

package (if metric frame, use (4) 3/8" hex nuts (item 33).

7.

Ensure that lock rings are securely snapped in place and did

not loosen during shipment.

8.

Install the pump into the system according to the installa-

tion instructions.

METRIC FRAME

1.

Unpack the pump and any supplied accessories and exam-

ine for damage. If damage is detected, save the packaging

and notify the carrier immediately.

2.

Make a hole if required for discharge piping in the optional

mounting plate (item 9) at desired location.

3.

Prepare to install the motor on the pump. Carefully place the

motor on the fan cover on a suitable, level work surface.

4.

Install key into motor shaft key slot. Align the keyway slot on

coupling half (item 8) and slide it into motor shaft. Set cou-

pling half flush with the end of the motor shaft and tighten

both set screws with 1/8” Allen wrench to 70 in-lbs. (7.9 N-m).

5.

Install the metric motor adapter flange (item 2) on the motor

with (4) socket head cap screws (item 4). Use lock washers

(item 3) on 80 frame motors only (90 frame motors do not

require any washers). One side of the adapter has a B stamped

on it and this side faces the motor on an 80 frame. The other

side has an A stamped on it (with hex nut recessed bolt

holes). This side (side A) is for 90 frame motors.

6.

Proceed to steps 5-8 in section “Pumps without Motors -

56C/143-145TC Frame.”

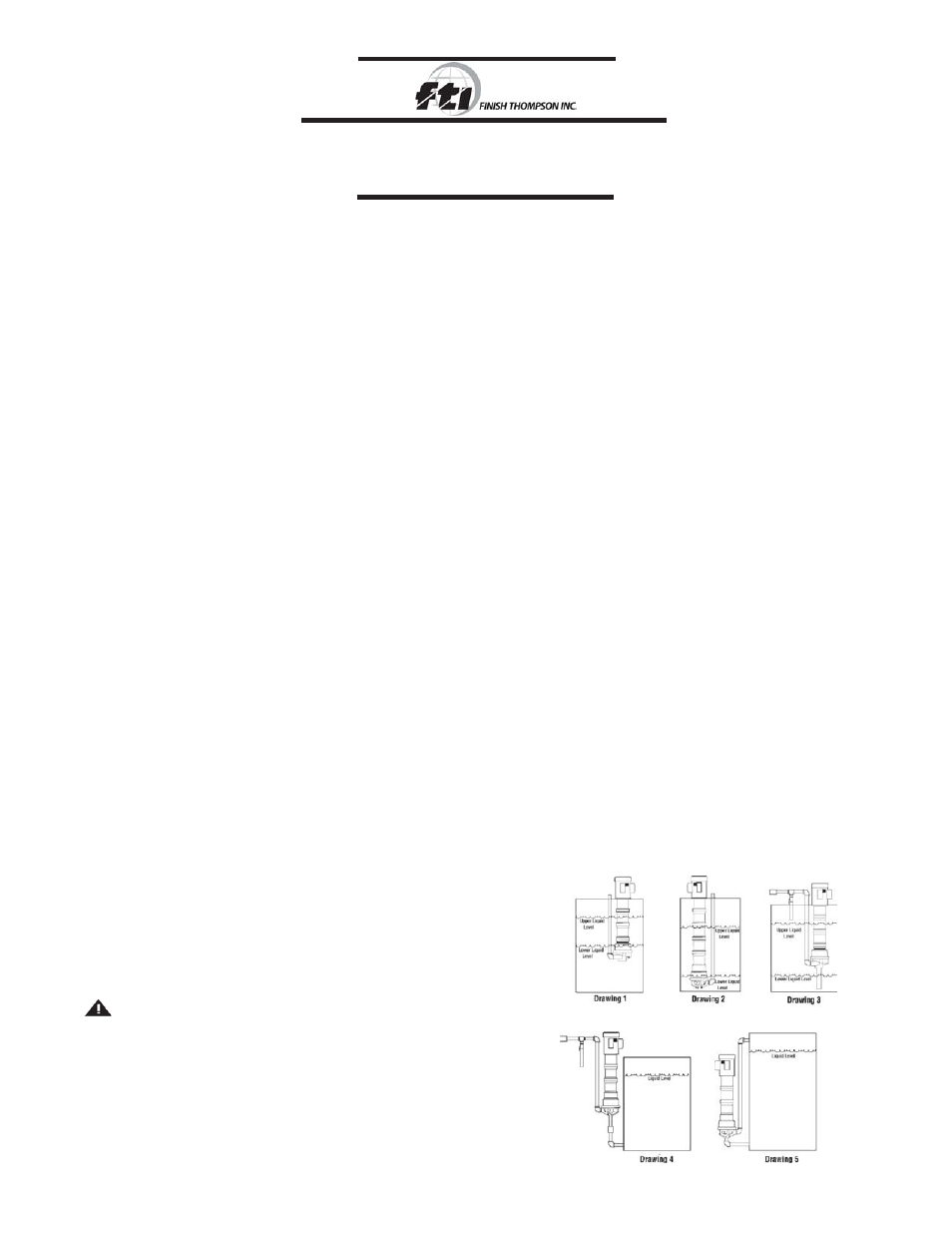

INSTALLATION

The VKC Series is a versatile pump designed to be operated in a

variety of mounting configurations. The pump can be mounted

either inside or outside of a tank or sump.

Note: Drawings for illustration only. Pumps need to be properly

supported when installed.

VKC 11 SERIES

Sealless, Non-Metallic Vertical Pumps

Installation and Maintenance Instructions

Pat. No. 5,708,313

Figure 1

Figure 1

Figure 1

Figure 1

Figure 1