Premier series - thermoplastic led combo sign, Unit testing, Manual testing – Emergi-Lite Premier Series Thermoplastic Combination Battery Unit and Exit Sign User Manual

Page 2: Automatic testing and diagnostics

Premier Series - Thermoplastic LED Combo Sign

Emergi-Lite

Tel: (888) 552-6467

Fax: (800) 316-4515

www.emergi-lite.com

03/10 750.1401 Rev. C

2/2

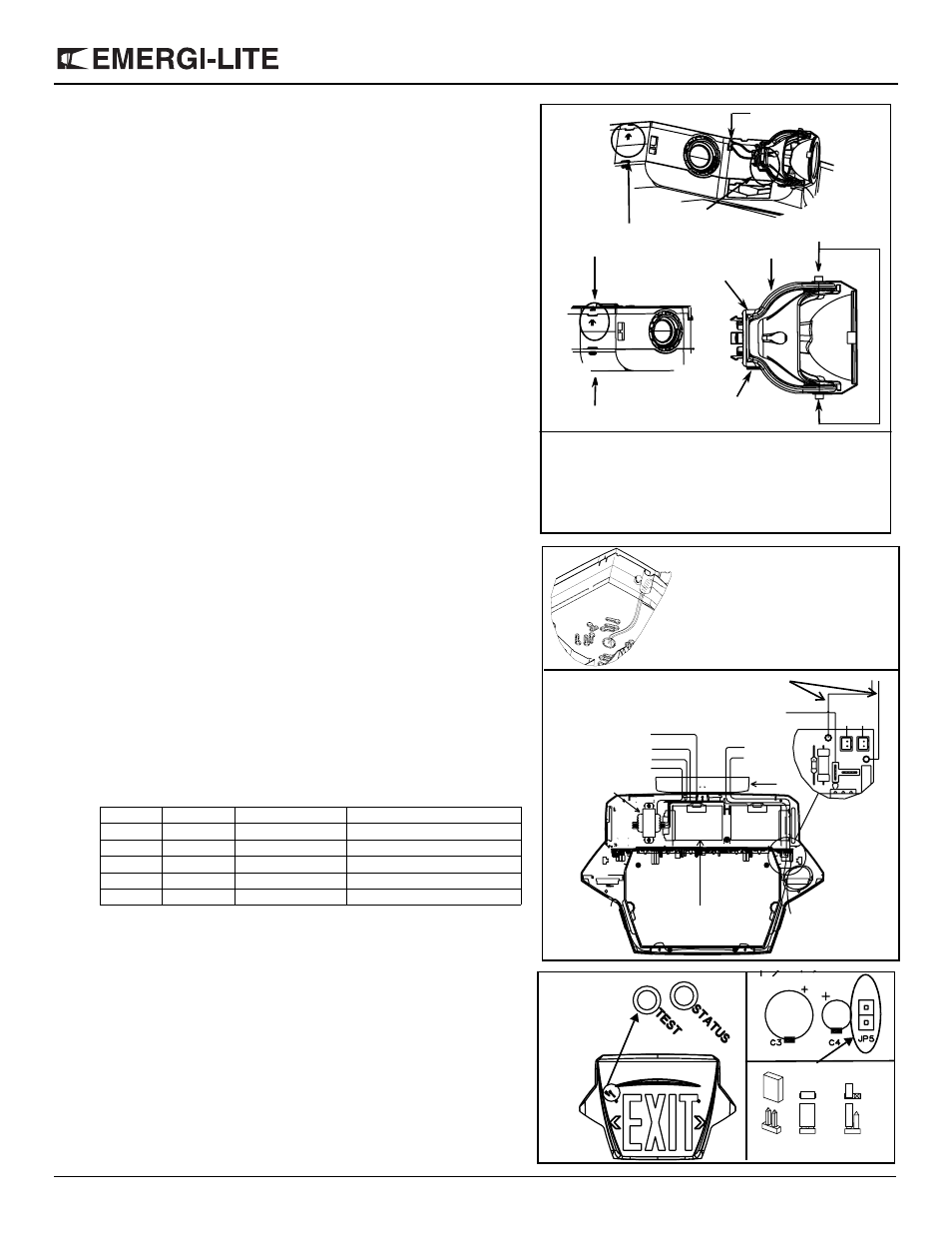

hole plug(5). Feed AC supply leads (and DC leads for remote lamps if

applicable) out through top opening and then through canopy. Remove the

canopy lock(12). Snap the canopy into the opening on top of frame. Rein-

stall the canopy lock into the canopy. Secure the assembly with canopy

housing screw(11) (See Fig. 1). Make the proper wire connections. The

“Quick-install” canopy is equipped with ribs allowing you to hang the unit

spider plate to facilitate wiring (See Fig.4). Feed the excess wire into the

junction box. Unhook unit and slide ribs on canopy into designated

notches on the spider plate (See Fig. 4). Secure the canopy to the junction

box using the canopy screws provided(10).

6. Install battery(s) and wires.

7. Remove the appropriate chevron(s) on the exit door by holding sign with both

hands. Push chevrons from the inside with thumb (See Fig. 2). You will need to

unsnap the diffuser panel to do so.

8. Connect battery “T Connector” to PCB (“B” connection) (See Fig. 6

).

9. Remote lamp(s) connection : Feed external DC+ & DC- wires through unit and

connect to internal wires using wire nuts provided (See Fig. 6).

10. Reinstall combo door(s). Fasten screws (only for some models).

11. Remove lenses (See Fig. 3) and discard plastic bags. Adjust the lamps in

appropriate position. Re-install both lens.

12. Energize AC. Sign will illuminate.

Note — DC input voltage is 6 or 12 volts depending on unit type.

Unit testing

Manual testing

Press test switch. Legend will flicker, but remain lit. On release, external green

LED will illuminate, and automatic charger will restore battery to full charge.

Automatic testing and diagnostics

The automatic testing and diagnostic function includes a micro-controller which

self-tests the unit on a monthly basis and identifies as well displays failures of the

electrical components: battery, battery charger, lamps, LEDs.

Self-test

The self-test is performed every months for 1 minute, every 6 months for

30 minutes, and annually for 90 minutes.

Diagnostic function

The diagnostic function uses an external green LED indicator. Service is

required if the green LED blinks indicating that an alarm condition is

detected (See Fig. 7).

For Nexus models, refer to “Nexus addendum”.

Units with automatic testing are shipped “non-audible”. If you wish to make the unit

“audible” simply re-orient the jumper “JP5” as shown in figure 8.

Maintenance —

None required. If AC supply to the unit is to be disconnected for

2 months or more, the battery must be disconnected.

Note — NiMH (Nickel Metal Hydride) batteries are shipped discharged and need

to be connected to an AC supply for 10 minutes before start-up test procedure, 24

hours to charge to meet a 30 minute discharge or 96 hours to reach full charge.

o

Green

Steady On

AC On

o

Red

Steady On

Battery Disconnect

-o

Red

Blinking

Battery Failure

o-o

Red

Two Blinks

Charger Failure

o-o-o

Red

Three Blinks

Lamp Failure

o-o-o-o

Red

Four Blinks

LED Failure

Support

Stopper

Stopper

Arrow on Central housing

points towards the “front side”

“Back side” of unit

Apply pressure here

when handling

No Stopper

(Facing “Back side” of unit)

Lamp wire groove

Figure 5

Feed Wires Through Plastic

Conduit (Wall Mount Only)

120 VAC Black

White Neutral

Ground

Blue - DC

Red + DC

DC +

DC -

Canopy

Remote DC Supply

DC Wires for

La

m

p

1

La

mp 2

Lamp 2

Batteries

Figure 6

Battery

L+

L-

Transformer

LED Strip

277 VAC Orange

Lamp 1

B

Remote lamp connections

L-

Assembly steps:

1.

Remove lamp assemblies from plastic wrapping.

2.

Place wires in respective grooves on the central housing.

3.

Align and snap in place with "stopper" oriented per Figure 5.

4.

Handle assemblies by applying a pressure on either end of the

support per Figure 5.

Test Switch

External Green LED

Figure 8

Figure 7

JP5

non-audible

audible