2 sensor installation or replacement – Teledyne 3350 - Microprocessor based control room monitor for personnel safety User Manual

Page 34

5-2

5 Maintenance

Model 3350

Teledyne Analytical Instruments

3. Insert a small flat-blade screwdriver into the slot in the receptacle at

the end of the power module and gently pry open the fuse

receptacle. The fuse holder will slide out. There are two fuses in use

and are visible in the clip.

4. Remove the bad fuse and replace it with a 5x20mm 0.5 A,

250 VAC, type T fuse(P /N F1130).

5. Replace the fuse holder into its receptacle, pushing in firmly until it

clicks.

5.1.2 AC With Battery Backup Version

1. Disconnect the AC power and place the power switch, located on

the rear panel of the control unit, in the O position.

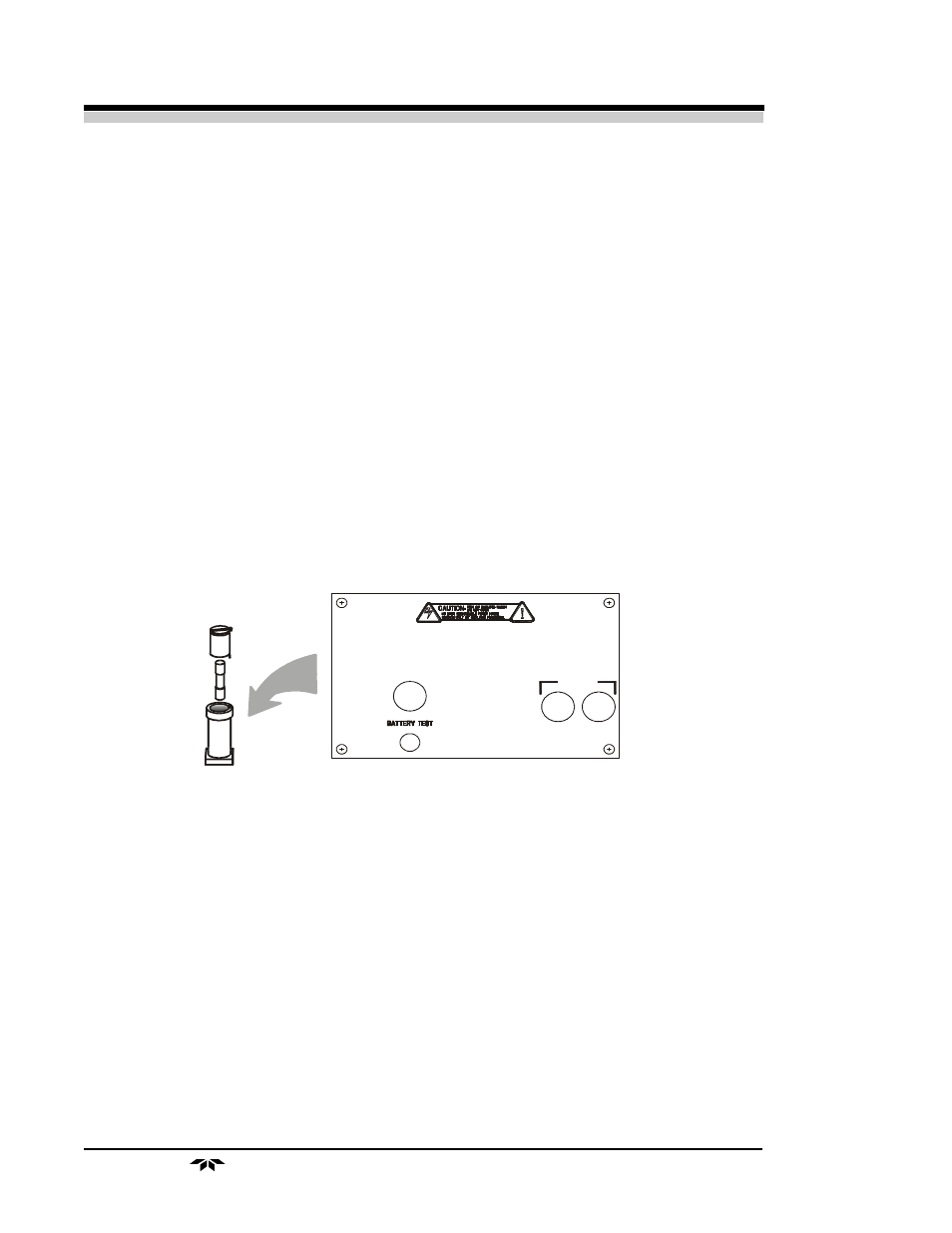

2. Place a small screwdriver in the notch of the fuse holder cap, push in

and rotate 1/4 turn. The cap will pop out a few millimeters. Pull out

the fuse holder cap and fuse, as shown in figure 5-2.

Figure 5-2: DC Battery Backup Fuse Replacement

3. Replace fuse by reversing process in step 1, by removing the bad

fuse and replace it with a 5 x 20mm 0.25A, 250VAC, Type "T" fuse

(P/N F1128) and 0.50A, 250VAC (P/N F1358).

5.2

Sensor Installation or Replacement

5.2.1 When to Replace a Sensor

The Micro-Fuel Cell typically provide almost constant output through their

useful life, and then fall off sharply towards zero at the end. You will find that

very little adjustment will be required to keep the analyzer calibrated properly

during the duration of a given cell’s useful life.

If large adjustments are required to calibrate the instrument, or calibration

cannot be achieved within the range of the

Δ∇ buttons, the cell may need replac-

FUSE

0.50 AMP

FUSE

¼ AMP