Teledyne 3350 - Microprocessor based control room monitor for personnel safety User Manual

Page 25

3-9

Alarm Oxygen Monitor

Installation 3

Teledyne Analytical Instruments

ment when calibrated using the monitored atmosphere

or a span gas of unknown composition, will be meaning-

less.

Preliminary—If not already done: Power up the Analyzer and

allow the LED reading to stabilize.

Procedure:

1. Expose the sensor to ambient air or instrument grade air (20.9%

oxygen). Allow time for the analyzer to achieve equilibrium.

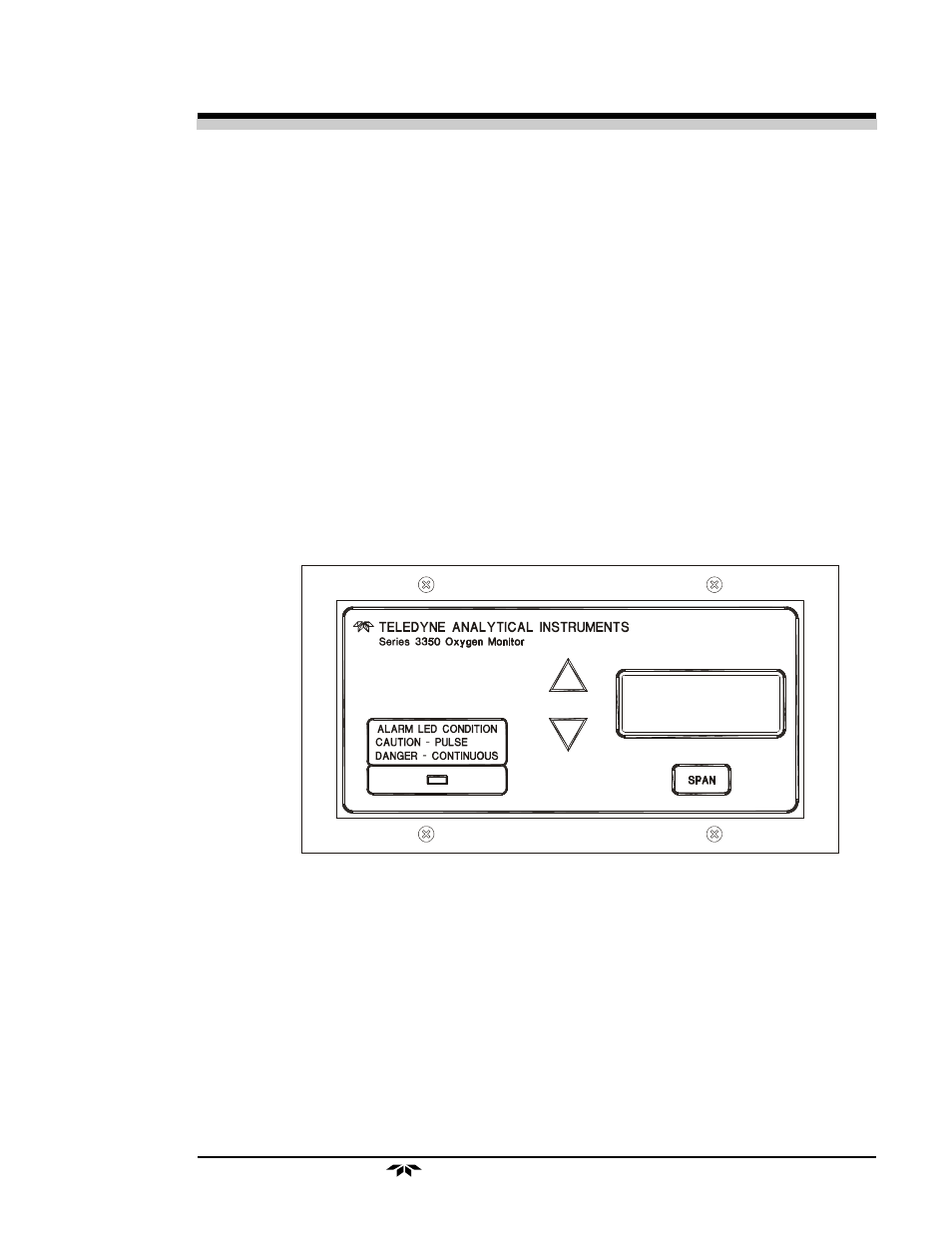

2. Press the SPAN button once.

3. Immediately (within 5 seconds) press either the

Δ or ∇ button

until the display is stable and reads 20.9%.

The unit is now calibrated. (also see section 4 operation)

Note:

The alarms will be disabled for about 25 seconds after the SPAN

button is released. Disabling the alarms allows air to be cleared from

the sensor without tripping any alarm set below span (20.9%).

Figure 3-6 Front Panel Membrane (Control Unit)

3.7 Operation

Once the instrument has been installed, calibrated, and the power turned

on, it will continuously monitor the oxygen level within the environment it is

placed. The oxygen level is displayed on the digital meter. The response

time of the instrument will depend on the actual Micro-Fuel Cell (MFC)

installed. With the class B-3 MFC installed, the response time is less than 15

seconds at 25°C. The table below indicates the response time for some

MFCs typically used in the Model 3350.