Teledyne 3350 - Microprocessor based control room monitor for personnel safety User Manual

Page 12

2-2

2 Operational Theory

Model 3350

Teledyne Analytical Instruments

2.2.2 Anatomy of a Micro-Fuel Cell

The Micro-Fuel Cell is made of extremely inert plastic (which can be

placed confidently in practically any environment or sample stream). It is effec-

tively sealed, though one end is permeable to oxygen in the sample gas. At the

permeable end a screen retains a diffusion membrane through which the oxygen

passes into the cell. At the other end of the cell is a connector and temperature

compensation network (restrictors and thermistor) on a printed circuit board.

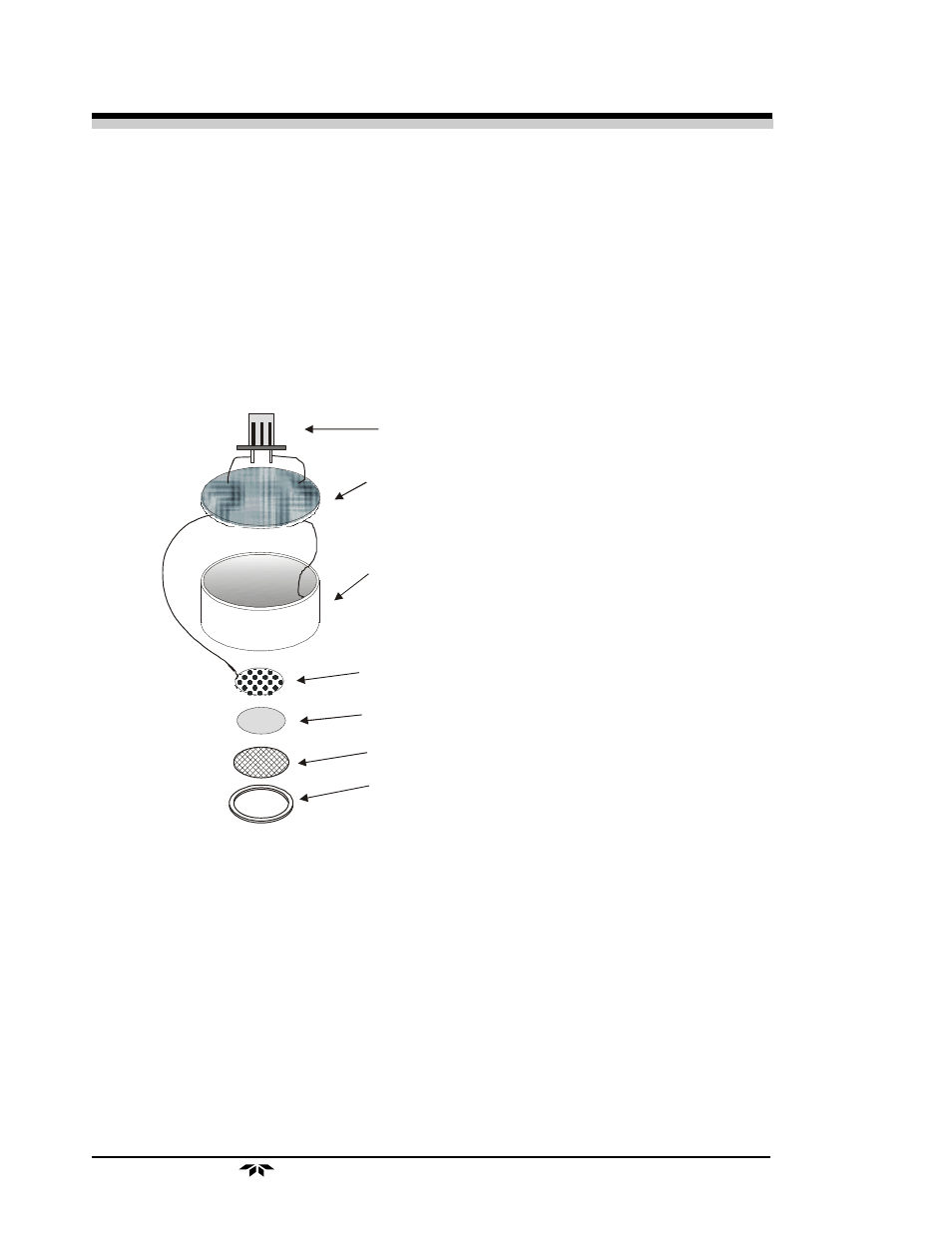

Refer to Figure 2-1, Basic Elements of a Micro-Fuel Cell, which illus-

trates the following internal description.

Figure 2-1. Basic Elements of a Micro-Fuel Cell (not to scale)

At the sensing end of the cell is a diffusion membrane, whose thickness is

very accurately controlled. Near the diffusion membrane lies the oxygen sensing

element—the cathode.

The anode structure is larger than the cathode. It is made of lead and is

designed to maximize the amount of metal available for chemical reaction.

The space between the active elements is filled by a structure saturated with

electrolyte. Cathode and anode are wet by this common pool. They each have a

conductor connecting them, through some electrical circuitry, to one of the

external contacts in the connector receptacle, which is on the top of the cell.

Electrical Connector

Circuit Board

with temperature compensation network.

Cathode

Anode

Clamp

Teflon Membrane

Screen