Maintenance – Fulton Edge ICX or FB-F Vertical Tubeless Boilers (Steam), Gas Fired User Manual

Page 63

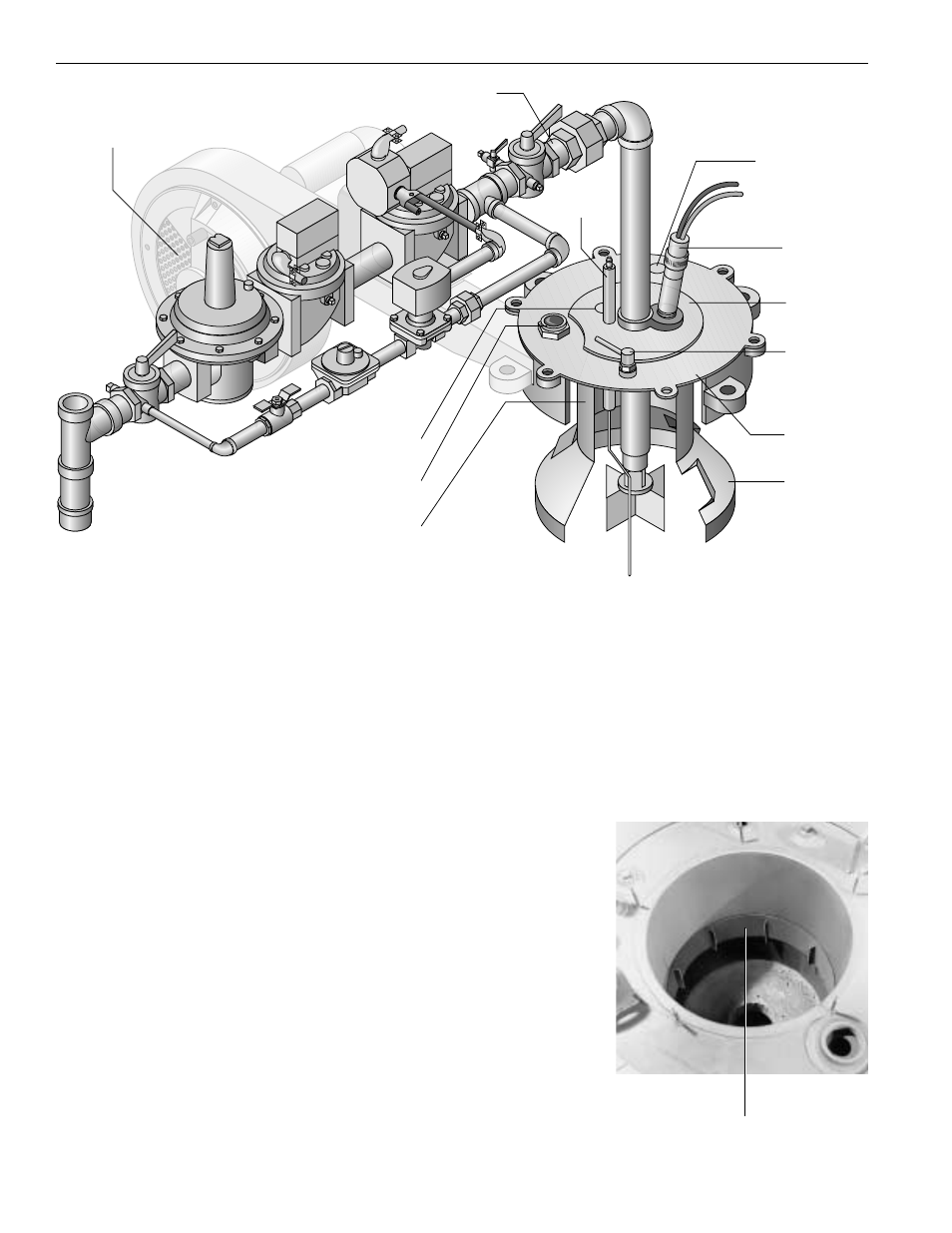

Primary

Air Gate

Burner

Viewing Port

Blast Tube

Viewing Port

Blast Tube

Scanner

(4–15 HP)

Flame

Rod(s)

*

Gas Head

Scanner

Location

(20–60 HP)

Burner

Plate

Air Deflector

*

If Applicable

Top Plate

Secondary

Air Gate

Flame Rod Adjustment for Fulton

Gas Fired Steam Boilers

a) The flame rod adjustment is made

by loosening the lock nut and turning

the porcelain portion of the flame rod

clockwise or counter clockwise.

Whenever a flame rod is moved, care

should be taken to ensure that the

flame rod does not ground out by

touching the metal surface of the blast

tube assembly. A keyboard display

module can be used to determine

proper signal response. It is neces-

sary to establish pilot so that the main

gas valve will engage. The main

flame should be adjusted to an

acceptable flame signal to ensure con-

tinued performance. A poor signal will

result in the boiler flame programmer

going off on safety.

b) A single flame rod is used on 4-15

HP Fulton Boilers, and two flame rods

on 20 and 30 HP. If the boiler has two

flame rods, adjust the flame rod in the

burner plate first, with the outside one

disconnected. After a good pilot signal

is established on the inside flame rod,

then the outside flame rod can be

hooked up and the signal adjusted for

proper responses.

c) If a signal is erratic after adjusting

the flame rod, the main and secondary

air supplies may need adjusting. If a

flame rod is cracked or broken, the

porcelain will have to be replaced to

get a proper signal.

Flame Scanner Adjustments for

Fulton Gas Fired Steam Boilers

a) Flame scanner adjustments are

made with the detectors installed and

the burner running. It is essential to

obtain optimum flame signal detection

for safe and continual operation of the

control relay.

b) If a scanner is inoperable, it may

prove the detector is working and only

an adjustment to the pilot flame is

needed to improve the signal.

c) If the scanner is found to be

defective, replace.

NOTE:

The scanner is located on the out-

side edge of the burner top plate for

20-60 HP.

d) For the RM7800 Series use a key-

board display module or volt meter,the

flame safeguard will require a 1.25

VDC signal to pull in the main flame.

Then a maximum signal should be

obtained on main flame (5.0 VDC).

e) Adjustments to establish a good

signal may include the following items:

1) Primary and secondary air

adjustments.

2) Increasing the pilot gas through the

pilot gas regulator.

Checking the Stainless Steel

Combustion Ring on Fulton

Gas Fired Steam Boilers

a) The stainless steel combustion

ring in Fulton gas fired boilers

(50-60 HP only) are designed to bring

quick and effective flame transfer to

the fire wall. The ring should fit

securely and tight against the furnace

wall for best results.

b) The ring should be inspected for

distortion in the event of poor com-

bustion which could result in flame

failures.

54-G 1/01

Maintenance

Stainless

Steel

Combustion

Ring