Description/instructions – Fulton Edge ICX or FB-F Vertical Tubeless Boilers (Steam), Gas Fired User Manual

Page 49

42a-G 1/01

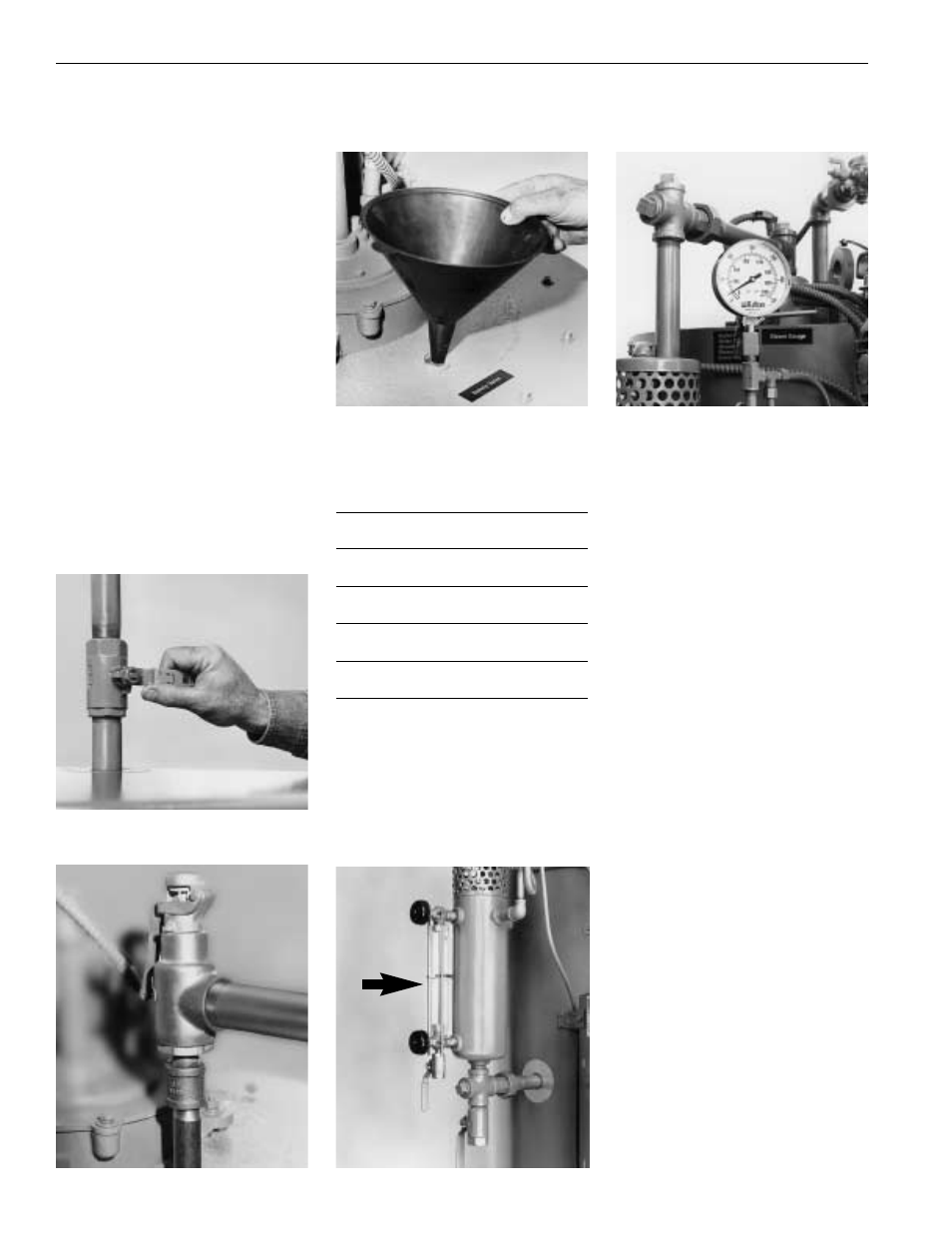

Installation Check Points

1) Make sure all piping connections

are complete and tight.

2) Make sure the pressure controls

are adjusted properly.

3) Make sure all electrical connections

in the control panel box, the water col-

umn, and elsewhere are secure.

4) Make sure the door in the boiler

room is closed. Combustion air cont-

aminates can cause damage to the

boiler jacket and stack.

NOTE

After installation is complete and

prior to operation the pressure

vessel should be cleaned.

Cleaning the Pressure Vessel

a) After the boiler has been installed

and before it is placed in service it is

advisable to purge the pressure vessel

of any oil film,dirt, or other impurities.

Clean the pressure vessel as follows:

1) Isolate the boiler from the system

by shutting off the main steam valve.

2) Remove the steam safety valve.

3) Mix washing soda with water in a

one-gallon container and pour it into

the boiler through the steam safety

valve opening.

4) The mixture of washing soda to

water is as follows:

Boiler Size

Soda

4 - 6

1 lb. (454g)

10 - 15

2 lb (908g)

20 - 30

3 lb (1362g)

40 - 50

3-1/2 lb (1589g)

60

4 lb (1816g)

5) Replace the steam safety valve.

6) Fill the boiler with water. Water

level is about center in the water

gauge glass.

7) Generate 15 PSI (1.054 kg/cm

2

)

of steam and shut off the boiler.

Allow this hot solution to remain in

the boiler for 10 minutes.

8) Drain and flush the boiler twice

with fresh water.

9) To remove all the oil and dirt from

the main steam and the condensate

return lines, allow the returns to go

into a floor drain or a safe discharge

point for the first week of operation.

CAUTION

Do not store halogenated hydro-

carbons near or in the boiler room.

In general, ensure that the boiler area

is in conformance with established

boiler room requirements. Review

national and local codes

.

As a final checkpoint, again,

Water Treatment

We cannot emphasize enough the

importance of proper water treat-

ment: Water analysis should be

made by a competent water treat-

ment concern and their recom-

mendations should be followed.

Description/Instructions