Detroit Radiant Products Company DES3 Series User Manual

Page 35

35

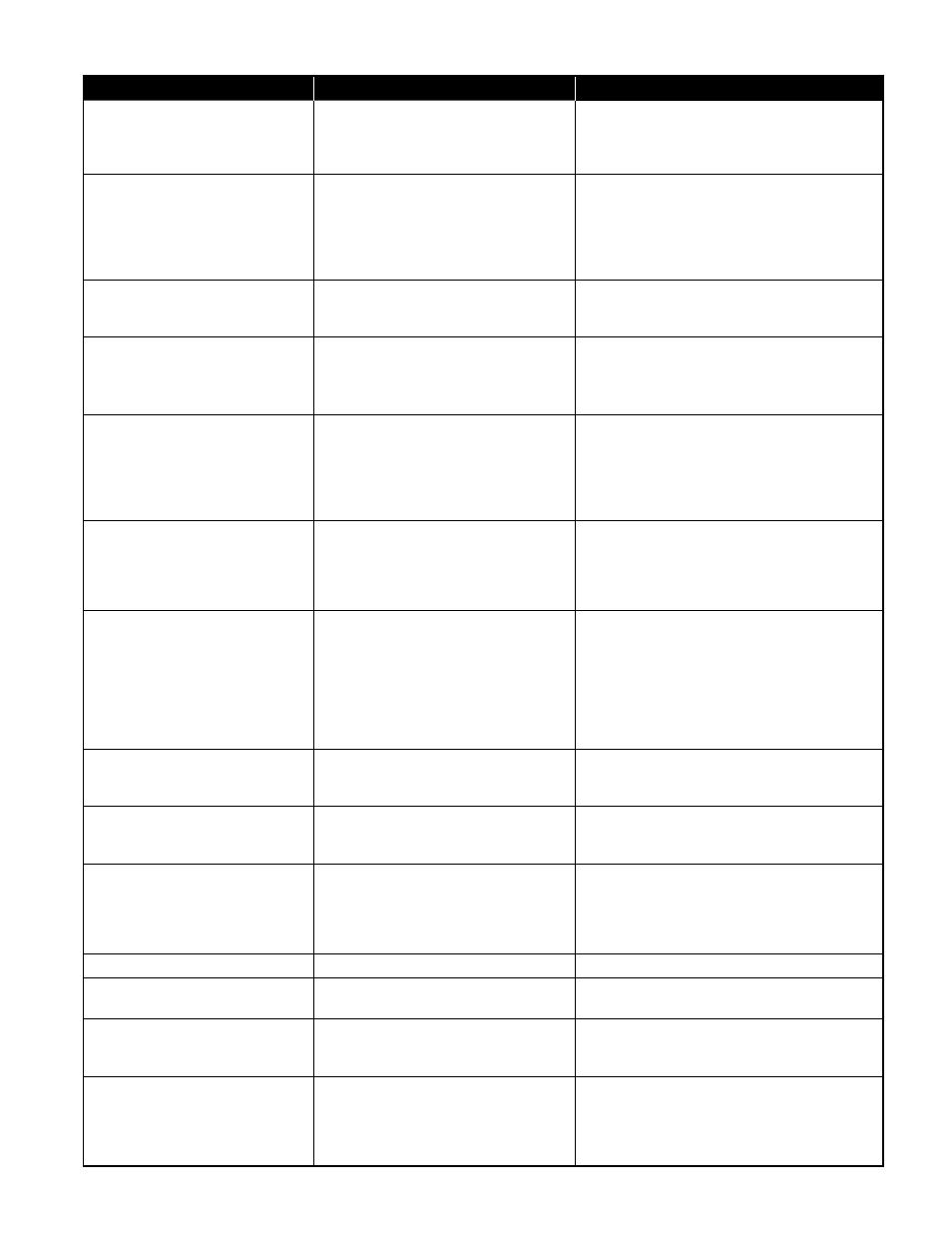

Symptom

Possible Cause

Corrective Action

Thermostat closed, fan doesn’t

operate.

• Blown fuse.

• Faulty thermostat.

• Loose or disconnected wire.

• Faulty fan.

• Replace.

• Replace.

• Repair as required.

• Lubricate, repair or replace.

Thermostat closed. Fan

operates. Switch does not close.

• Loose or disconnected wire.

• Box lid or gasket not in place.

• Plugged pressure switch lines.

• Plugged or restricted exhaust vent.

• Baffle location incorrect.

• Faulty pressure switch.

• Repair as required.

• Put in place.

• Clean as necessary.

• Remove foreign matter.

• Re-position baffles at vent end.

• Replace only. Do not adjust.

Thermostat closed. Fan

operates. Pressure switch

closes. No glo-bar igniter.

• Faulty glo-bar igniter.

• Faulty circuit board.

• Replace.

• Replace.

Thermostat closed. Fan

operates. Pressure switch close.

Glo-bar energizes. Valve does

not open.

• Disconnect gas valve wires.

• Faulty circuit board.

• Faulty gas valve.

• Repair as required.

• Replace.

• Replace.

Thermostat closed. Fan and

glo-bar /spark igniter operate.

Ignition occurs, burner cycles

off in less than 60 seconds.

• Low gas pressure.

• Baffle improperly positioned.

• Faulty pressure switch.

• Restricted flue vent.

• No electrical ground.

• Reversed polarity.

• Provide required gas pressure.

• Re-position baffle at vent end.

• Replace.

• Remove foreign matter.

• Connect electrical ground to junction box.

• Repair.

Thermostat closed. Fan and glo-

bar /spark igniter operate. After

45 seconds glo-bar shuts off

(15 seconds for spark igniter).

No ignition.

• Closed gas supply.

• Dirty or restricted orifice.

• Faulty valve. Disconnected wire.

• Inlet pressure exceeds 14 inches

W.C.

• Open all gas connections.

• Remove. Clean with a soft object.

• Replace or repair.

• Lower inlet pressure.

Loss of heater efficiency.

• Low gas pressure.

• Dirty or restricted orifice.

• Foreign matter inside burner.

• Unit cycles on and off.

• Reflector is dirty.

• Reflector not in place.

• Clogged fan blower.

• Provide required gas pressure.

• Remove. Clean with a soft object.

• Clean as necessary.

• Check previous symptom.

• Clean with aluminum cleaner and soft

cloth.

• Put in place.

• Clean.

Radiant tube leaking burnt

gases.

• Loose tube connections.

• Holes or cracks in radiant tubes.

• Ensure that tubes are fully connected

and clamped properly.

• Replace.

Condensation.

• Stack length is too long.

• Light gauge vent stack used.

• Contaminated combustion air.

• Shorten stack length.

• Minimum of 26 ga. vent pipe required.

• Provide fresh air inlet duct.

Tube bowing.

• Insufficient combustion air.

• Over fired.

• Contaminated combustion air.

• Heater unable to expand properly.

• Provide 1 sq. in. of free air for every

5,000 BTU/h of input.

• Check gas pressure and orifice size.

• Provide fresh air inlet duct.

• Remount with flexible inlet or vent pipe.

Tube corroding.

• Contaminated combustion air.

• Provide fresh air inlet duct.

Visual inspection of burner

operation not possible.

• Dirty or sooted sight glass.

• Unit mounted upside-down.

• Remove, clean or replace.

• Mount correctly.

Stack sooting.

• Insufficient combustion air.

• Improper gas.

• Dirty fan or blockage.

• Provide 1 sq. in. of free air for every

5,000 BTU/h of input.

• Correct with proper gas input (or clean).

Odor or fumes in space

(normal during first firing and

will subside after initial burn off,

approximately 20 minutes).

• Vaporized solvents decomposing

when contacting radiant tubes.

• Evaporation of oils, solvents at floor

level.

• Loose tube / vent connections.

• Provide proper ventilation.

• Provide proper ventilation.

• Tighten tube clamps to 40-60 ft-lb.

• Seal vent pipes.

Chart 5.1

Troubleshooting Guide