Final heater assembly – Detroit Radiant Products Company DES3 Series User Manual

Page 23

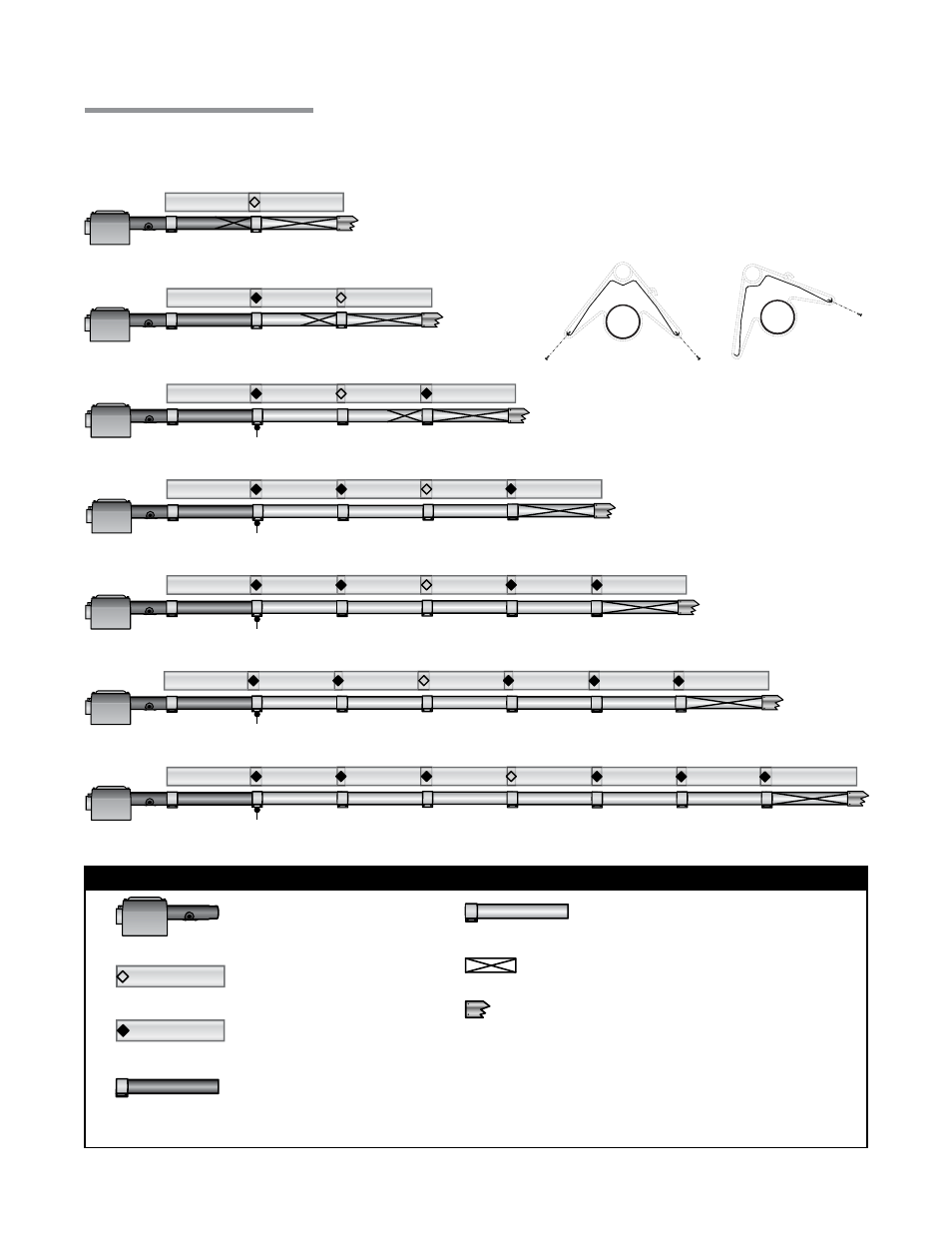

Chart 3.6

Tube Installation Sequence, Baffle Location and Secured Joints for Reflectors

30 Foot

40 Foot

*

*

*

*

*

Burner Control Box

w/16 in. Burner Tube

Key

Expansion Joint on

Reflectors

Secured Joint on

Reflectors

Primary Combustion

Chamber with Clamp

Radiant Tube

Exchanger with Clamp

Baffle Location

Secure vent material to exchanger with three #8

sheet metal screws. Seal with high temperature

silicone sealant. Do not use tube clamp.

23

20 Foot

Final Heater Assembly

3.0

Installation

•

Final Heater Assembly

*

A secondary combustion chamber is installed as the

second tube downstream from the burner control box on

150,000 to 200,000 BTU/h models. Refer to the Series

Insert Manual for installation requirements.

50 Foot

60 Foot

70 Foot

80 Foot

Stainless steel clamp on 150,000 to 175,000 BTU/h

models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000 BTU/h

models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000 BTU/h

models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000 BTU/h

models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000 BTU/h

models (P/N: TP-220).

NOTE: When securing joints on reflectors which

are rotated on an angle from horizontal, secure

joint only on top side of reflector to allow for

sufficient heater expansion and contraction.

1 to 45° Mounting Angle

0° Mounting Angle