Magnum Venus Plastech PATRIOT SSB Commissioning and instruction User Manual

Page 28

SSB_Auto Instructions Issue 05

Page28

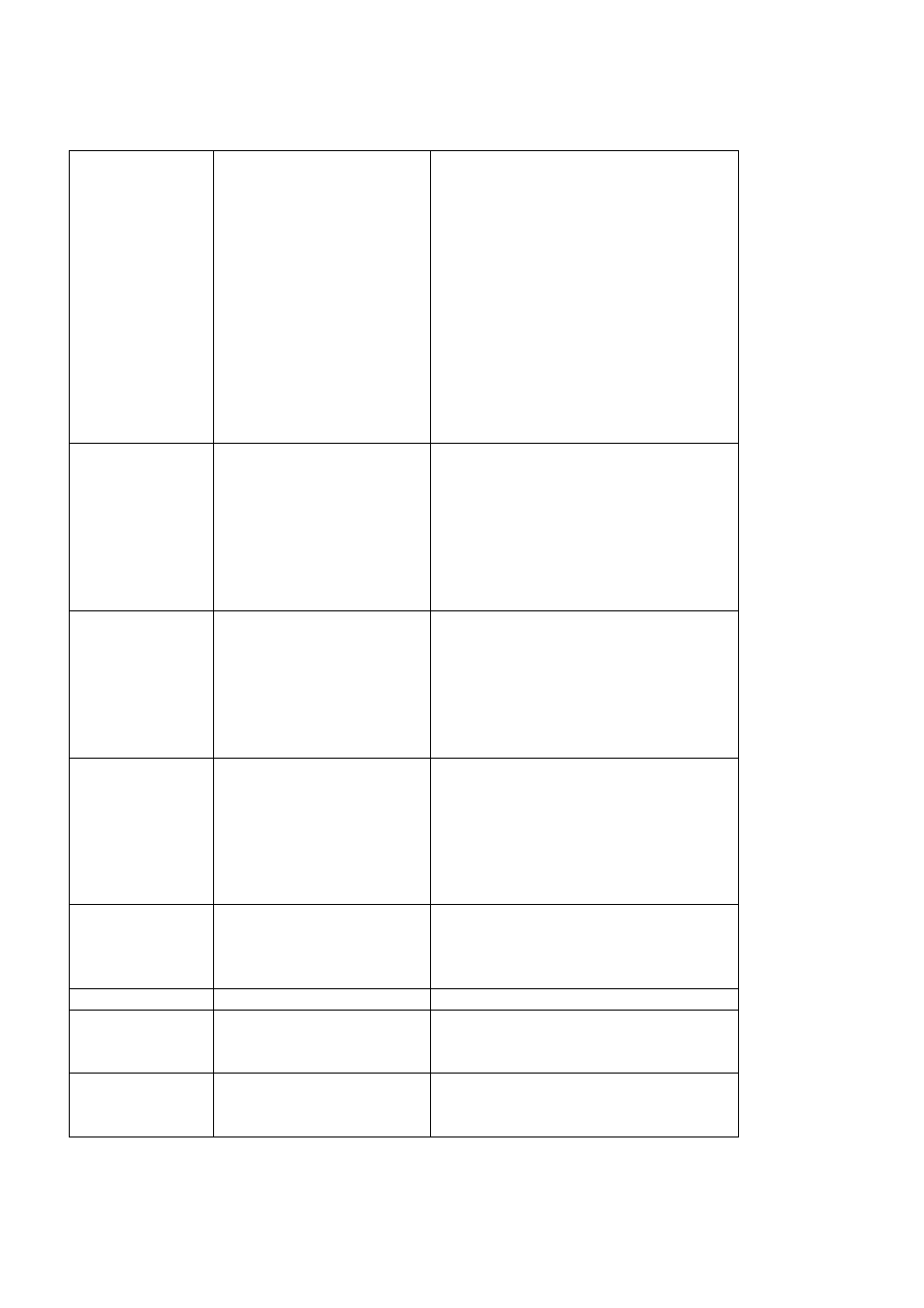

5. Catalyst head valve

has not fully opened

when commanded by

injection command

Check both the resin auto valve and

the catalyst auto valve have opened

.The Resin valve must fully open to

signal the catalyst valve to open.

Both should indicate their

respective open positions by the

Resin valve brass pin raised above

the red valve top by at least 7 mm.

The catalyst auto valve should

show the movement open by the

aluminium pin raised by at least 5

mm from the closed position.

Service the valve which is showing

signs of not fully opening.

6. Resin head valve

blocked .This condition

can happen if the

machine has been left

with resin in the system

for extended times

without use.

Internally clean and if necessary

renew internal parts.

Caution NOTE. Always replace the

resin valve locking M5 screws

securely after servicing the Resin

auto valve.

Catalyst flow

appears erratic

1. Air in catalyst feed

pipe or Fluid section

Re purge catalyst system. I

Contaminated catalyst also causes

bubbles in system. To remedy

empty entire catalyst system

including catalyst bottle . Wash out

with clean water. Refill with fresh

Catalyst

3. Catalyst Gassing

-Clean catalyst system of

contamination.

- Use AAP catalyst system as

MEKP has a greater tendency to

produce gas bubbles more readily

than the more stable AAP systems

Resin flow has

bubbles or

appears erratic

1. Air leaks in the resin

feed intake system.

1.Check all joints for leaks in intake

pipe work and fittings on the resin

pickup fluid section

2. Resin filter blocked

Clean resin intake filter

3. Resin Filler loading

too high

Lower viscosity of resin OR lower

pump speed until even flow on up

and down pump strokes is observed

Flush does not

clean efficiently

or appears

1.Low air supply

pressure

Ensure supply pressure between 6

to 8 bar