Magnum Venus Plastech DP-1000 (EPO3) User Manual

Page 20

If the pressure is not adequate to form a well-defined fan pattern, increase the MAIN PRESSURE until there is

just enough pressure to form a proper fan pattern.

Described in the following are possible problems and their solutions with fan pattern:

One Narrow Stream: The MAIN PRESSURE is too low for the material you are using (see Figure 16 on

previous page).

Solution

: Increase the MAIN PRESSURE. Increase the material’s temperature. Use a smaller nozzle size.

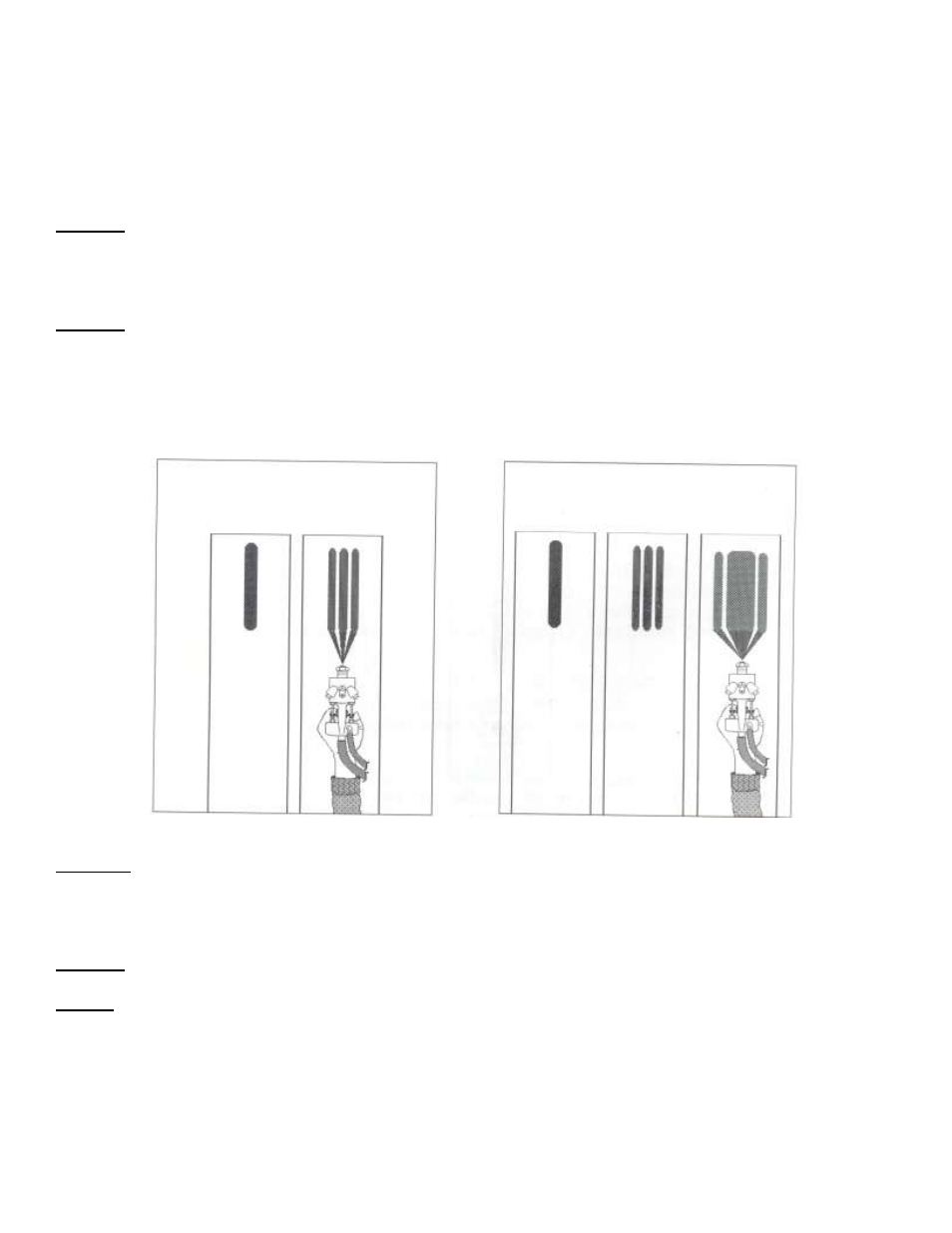

Three Heavy Fingers Horns are beginning to develop but the MAIN PRESSURE is still too low (see Figure

17).

Solution: Increase MAIN PRESSURE. Increase material pressure. Use a smaller nozzle size.

Middle Stream Not Full Width Middle Stream is wider but not the full width it should be for the nozzle (see

Figure 18).

Note: See Appendix B for spray nozzle list.

(Figure 17. Narrow Middle Stream Pattern) (Figure 18. Wider Spray Pattern)

Solution: Increa

se MAIN PRESSURE. Increase material’s temperature.

Pattern Near Full Width

There are well-defined fingers; however, there is little or no white frothing (air

bubbles) in the center of the sprayed material (see Figure 19)

Solution: Slightly increase t

he operating pressure. Slightly increase material’s temperature.

Result: PATTERN IS AT FULL WIDTH and the fingers are well-defined. White frothing appears in the

sprayed material. However, the white froth should disappear in less than 2 minutes (see Figure 20).

Note: This is considered the best general set of conditions for the fan pattern. Keep notes of the MAIN

PRESSURE and the material TEMPERATURE gauge readings when the pattern is correct.