Magnum Venus Plastech DP-1000 (EPO3) User Manual

Page 19

It is also possible t

o help compensate for this effect by proper selection of accumulator sizes on the “PUMP H.”

A hardener pump operating at an 8:1 ratio may be equipped with an accumulator having approximately 1/8 the

volume of the resin accumulator (4:1 at ¼, etc.).

When using accumulators at this reduced volume, the charging and testing procedure must be performed

correctly. Properly matched accumulators may prevent the necessity of pre-

pressurizing the “PUMP H” by

restricting recirculation.

Change to Operating Mode

Upon completion of the MAIN PRESSURE adjustment procedure, be sure that the 4 ball valves on the INLET

panel are set to the fully open position (see Section 3, Set Pump To Maximum Stroke Length).

Set the RECIRCULATION PRESSURE switch “OFF” and MAIN PRESSURE switch “ON.” Repeat this

procedure whenever the unit is placed in recirculation mode.

Note: The gun-head must be reassembled before pattern testing can be done.

Test Spray Patterns

Lay out a strip of paper for the spray test and perform the following test:

Note: You need two people for this test.

Turn on MAIN PRESSURE switch and adjust MAIN PRESSURE to 50 psi.

Turn RECIRCULATION PRESSURE “ON” and adjust the pressure until pump is operating at

approximately one stroke every two seconds.

When the gun trigger is pulled back, the air valve on the gun activates an air signal in the machine to switch

from recirculation air pressure to MAIN PRESSURE. The same air signal closes two ball valves on the INLET

PANEL and shuts off both recirculation lines. All fluid exits the gun nozzle rather than returning to the

containers.

The gun operator starts spraying onto the test strip and the second operator adjusts the MAIN PRESSURE

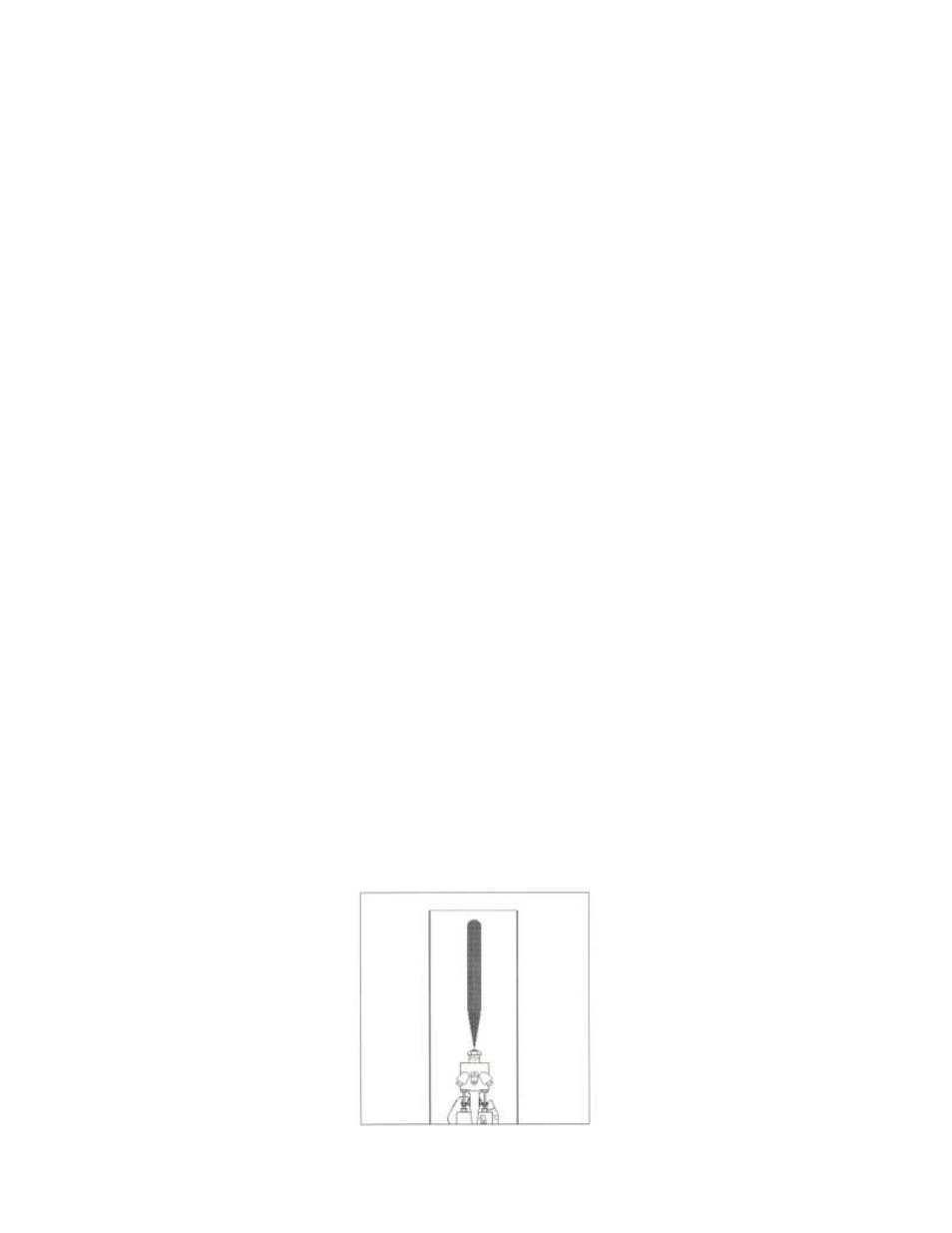

knob up or down as required for a proper spray pattern output (see Figure 16).

CAUTION: If you should stop spraying for any reason, immediately flush the gun-head using the

following procedure:

Place the gun-head into an approved container and push forward on the trigger until a steady stream

of solvent pours into the container).

(Figure 16. Initial Spray Pattern)