Chapter 5 – Magnum Venus Plastech DP-1000 (EPO3) User Manual

Page 17

CHAPTER 5

PRESSURE AND ADJUSTMENT

Select Injectors

Four injectors are supplied with each unit and must be selected for each application according to back

pressures developed by the variable-ratio pump (#1 is the largest, #4 is the smallest).

Typically the #3 injector should be used for 3:1 ratio materials and #4 injector should be used for 4:1 ratio

materials, etc. High ratio materials require less flow through the injector.

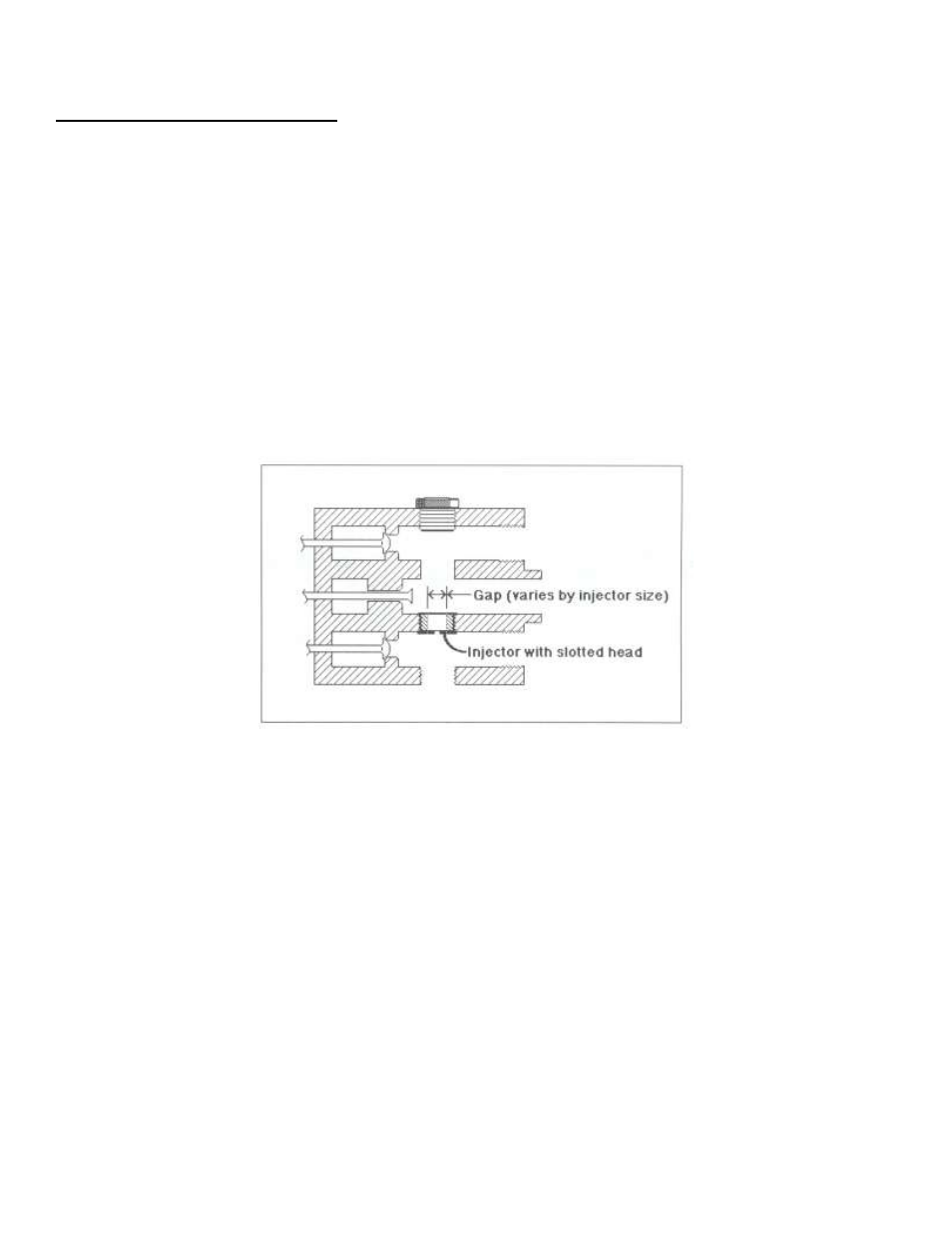

The orifice of the injector must be sized to maintain proper back pressure to the pump (see figure 13).

Viscosity, temperature, surface tension, and other factors affect the back pressure developed by this injector.

Because of the se factors, injector selection must always be done by trial-and-error. If pressures at the pump

gauges cannot be balanced within 200psi by injector selection, modify viscosity of materials by heating.

Select injectors according to flow rate and viscosity of materials.

(Figure 13. Select Injector)

Assemble Gun-Head

Grease all threads with compatible grease (usually Lubriplate

™).

Insert turbulent mixer in nozzle port (see Figure 14).

Assemble air-assist nozzle onto gun. Refer to MVP Nozzle charts (Appendix B) for nozzle

selections.

Insert injector into gun-head and screw in gun plug (see Figure 15).

Recirculate Material Again

WARNING: If Pump Runs Rapidly Shut Off Main Pressure Immediately!

To operate the unit in RECIRCULATION mode perform the following steps:

Turn MAIN PRESSURE switch “ON” and leave pressure regulator set at “0” (zero) to bring air

into the recirculation control system.

Turn RECIRCULATION regulator switch “ON” and slowly increase regulator pressure until pump

is cycling (priming) slowly. Wait until material is seen exiting recirculation hoses back to

material container in a steady stream before turning RECI

RCULATION switch to “OFF.”

Note: Unit should be left in recirculation mode if not operating or material will cool off in hoses and pumps.