Chapter 3 – Magnum Venus Plastech DP-1000 (EPO3) User Manual

Page 12

CHAPTER 3

PRIME THE UNIT

Special Conditions: Sensitive Materials

If your materials are extremely sensitive to moisture or contamination, it is advisable to first prime both

pumps with a compatible solvent to remove any oil residue from the unit. The solvent containers should

then be disposed of properly.

Use approved containers for all flushing and priming procedures.

Check hose Fittings

Check all hose fittings on the unit to be sure they are tight.

Fill Solvent Tank

WARNING: Wear Eye Protection When Working With Solvent!

To fill the solvent tank, perform the following steps:

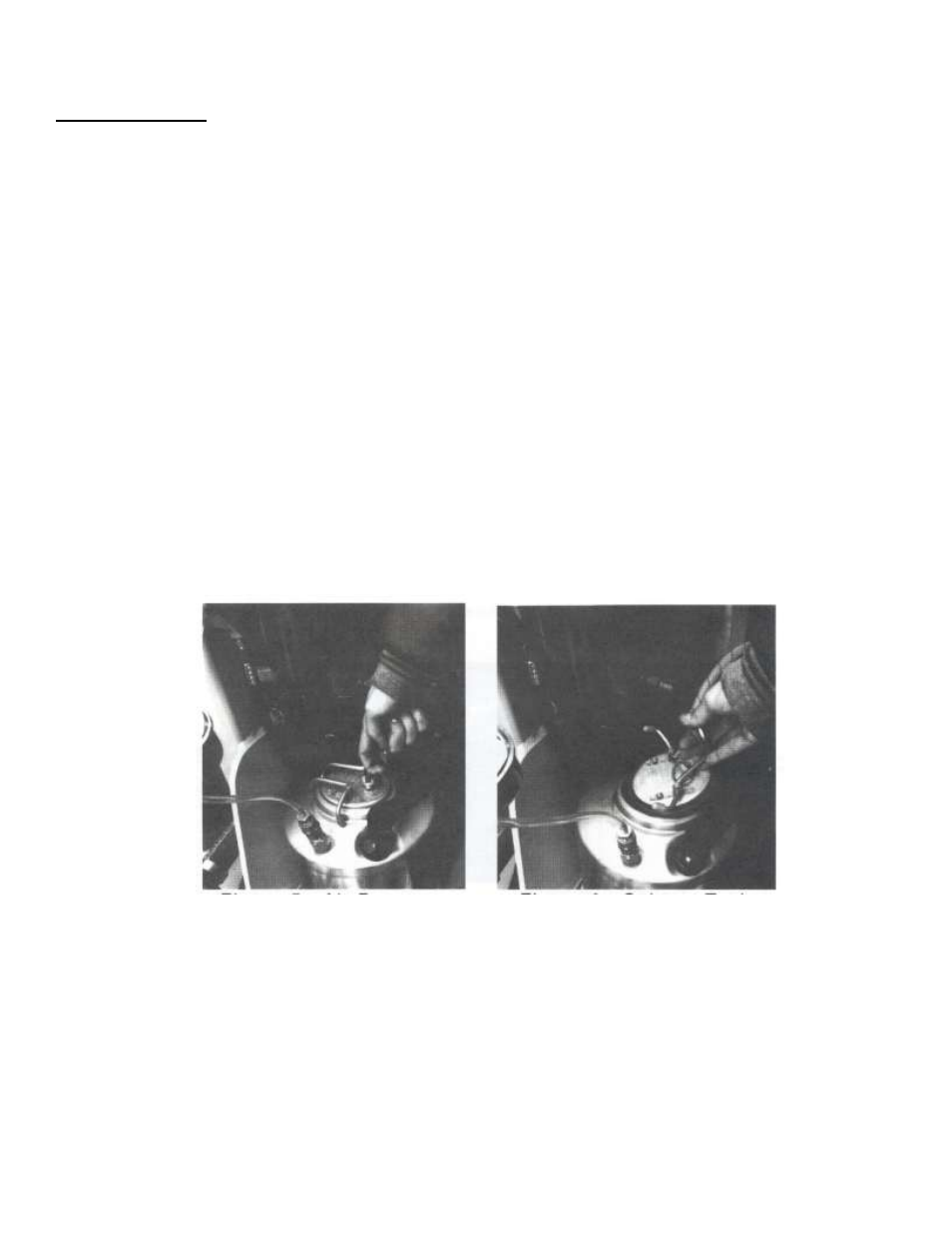

Release all air pressure from solvent tank by pulling the ring on the top of the pressure-relief valve and

turning ½ turn to lock open (see Figure 5). After all the air has exited through the valve, remove the solvent

tank hatch by pulling wire handle directly up and pressing hatch into solvent tank and turning hatch ½ turn

before removing (see Figure 6).

(Figure 5. Air Pressure Relief Valve) (Figure 6. Solvent Tank Hatch)

If solvent is splashed on the rubber O-ring, swelling can occur. Two O-rings have been supplied in case

this happens. However, the O-ring can be re-used. Set it aside and it will return to normal size overnight.

If necessary, the solvent tank can be removed from its bracket and hoses can be removed to allow easy

filling.

Pour solvent through opening in tank and fill to approximately 2/3 full with solvent. Do not over-fill or

solvent could be forced through back of the control panel. Replace solvent tank cover.

Close relief valve at top of tank by turning relief valve locking ring2/3 turn and allowing it to snap into place

(see Figure 7).