Magnum Venus Plastech DP-1000 (EPO3) User Manual

Page 14

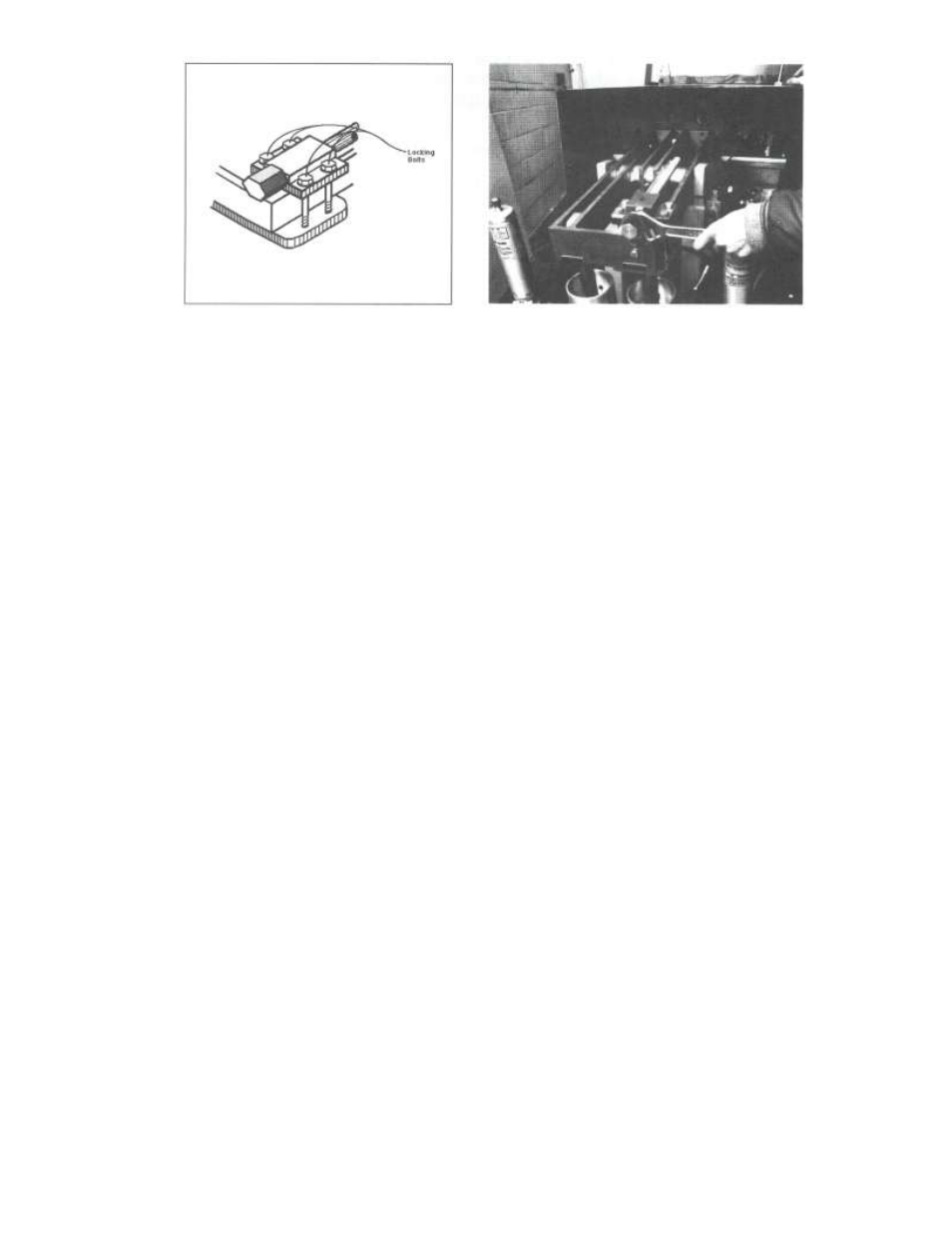

(Figure 10. Loosen Slave Arm Bolts) (Figure 11. Adjust Slave Arm Screw)

Check that all ball valves levers located on INLET PANEL are in the open position (parallel with the hoses).

The location of the ball valves is described in the following list:

One on each pump (2).

One on the RESIN RETURN HOSE.

One on the HARDENER RETURN HOSE.

Recirculate Material

Material must be recirculated past the gun-head through a return fitting to prime the unit. No material will

exit the gun. To recirculate material, perform the following steps:

Turn on MAIN PRESSURE switch

and leave pressure regulator set at “0” (zero). This brings air into the

recirculation control system.

Turn RECIRCULATION PRESSURE switch “ON” and slowly increase the regulator pressure until the pump

is cycling (priming) slowly.

Observe fluid pressure at resin and hardener pump pressure gauges attached to the pump as seen from

the back of the unit. Do not operate the unit if recirculation pressure is higher than 1200psi in either pump.

Adjust material viscosities by heating the container which shows the highest pressure on the pump gauge.

Use customer-supplied heating sources such as heat bands or water-jacket heating system on the material

containers. The EPO3 in-line heaters do not have enough wattage to efficiently heat large amounts of

material.

Apply heat until temperature of the material in the container is high enough to reduce viscosity to a point

where both pump pressures are balanced or nearly balanced. Do not heat material past 250º F.

While the unit is recirculating material, check for sudden movement of the pumps either on the upstroke or

downstroke. That would indicate gelled or hardened material is present on the ball seats requiring the

pumps to by disassembled and cleaned. Operation of pumps at high pressures with high viscosity

materials may also result in cavitation or diving movement on the pump which would need correcting.

Wait until material is seen exiting recirculation hoses back to material container in a steady stream before

turning RECIRCULATION PRESSURE switch to “OFF”.

Turn

RECIRCULATION PRESSURE knob counterclockwise to the “0” position.

Note: If pumps do not prime, slowly increase RECIRCULATION PRESSURE until pump is running at

approximately one cycle per second. If pump does not immediately slow down when material reaches fluid

piston, stop this procedure and use the following procedure.

Disconnect the green supply hoses from the inside of the INPUT panel.

Pull hoses free from the unit and pour material into the open hose fittings with hose raised high enough for

material to flow to bottom of the pump and wet the inlet balls.

The unit should now prime easily.