Operating procedures – Magnum Venus Plastech Quick Shot User Manual

Page 21

Quick Shot Operations Manual

Rev. 03/2013

Page | 21

Operating Procedures:

1. Move the catalyst pump to the desired catalyst percentage as noted on the slave

arm sticker and pin the bottom and top bearing block at the same percentage.

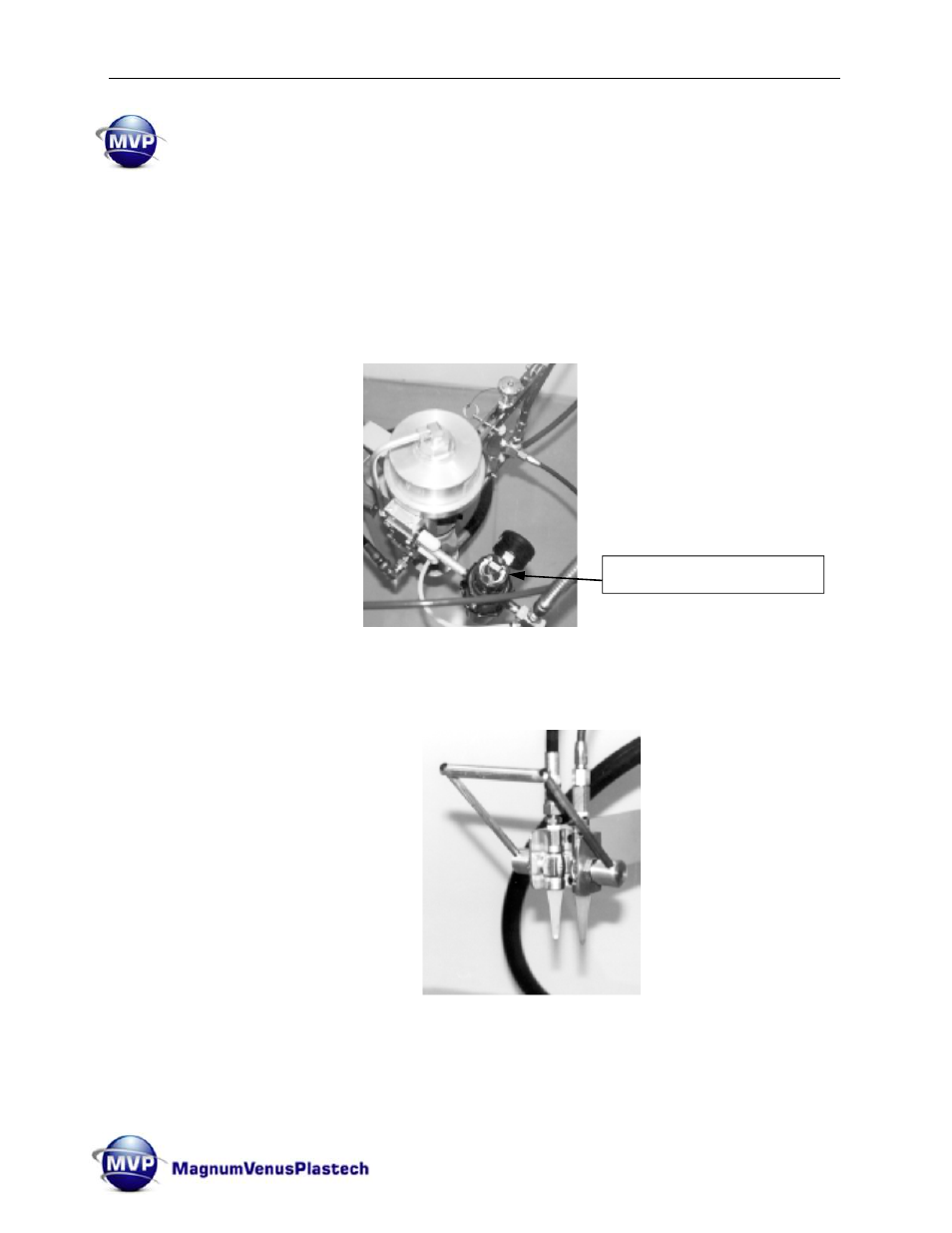

2. Turning the knob counter-clockwise on top of the regulator/filter combination unit

decreases air pressure to the resin pump. Turning the knob clockwise increases

air pressure to the resin pump. Turning the knob counter-clockwise until the

pressure gauge reads zero shuts the unit down. (See fig. 9)

3. When air pressure is attached to the pump, pulling the parallel ball valve down

will start resin and catalyst flow. Pushing the handle back up will shut the resin

and catalyst flow off, stalling the resin pump against the fluid pressure and

shutting it off. (See fig. 10)

Note: The best way to regulate the flow rate, or output of the machine is at the

regulator that controls the amount of air supplied to the resin pump. In other words,

the higher the regulated air pressure, the faster the pump will run. In practice, the

valve is either on or off. Any attempt to throttle the valve may negatively affect the

machine’s ability to meter the two materials in the appropriate quantities.

Regulator Control Knob

Fig. 9

Fig. 10