Alarm messages, Causes and actions to be taken, Anomalies codes – Liquid Controls HML210 IOM - LCMag User Manual

Page 40

HML 210

40

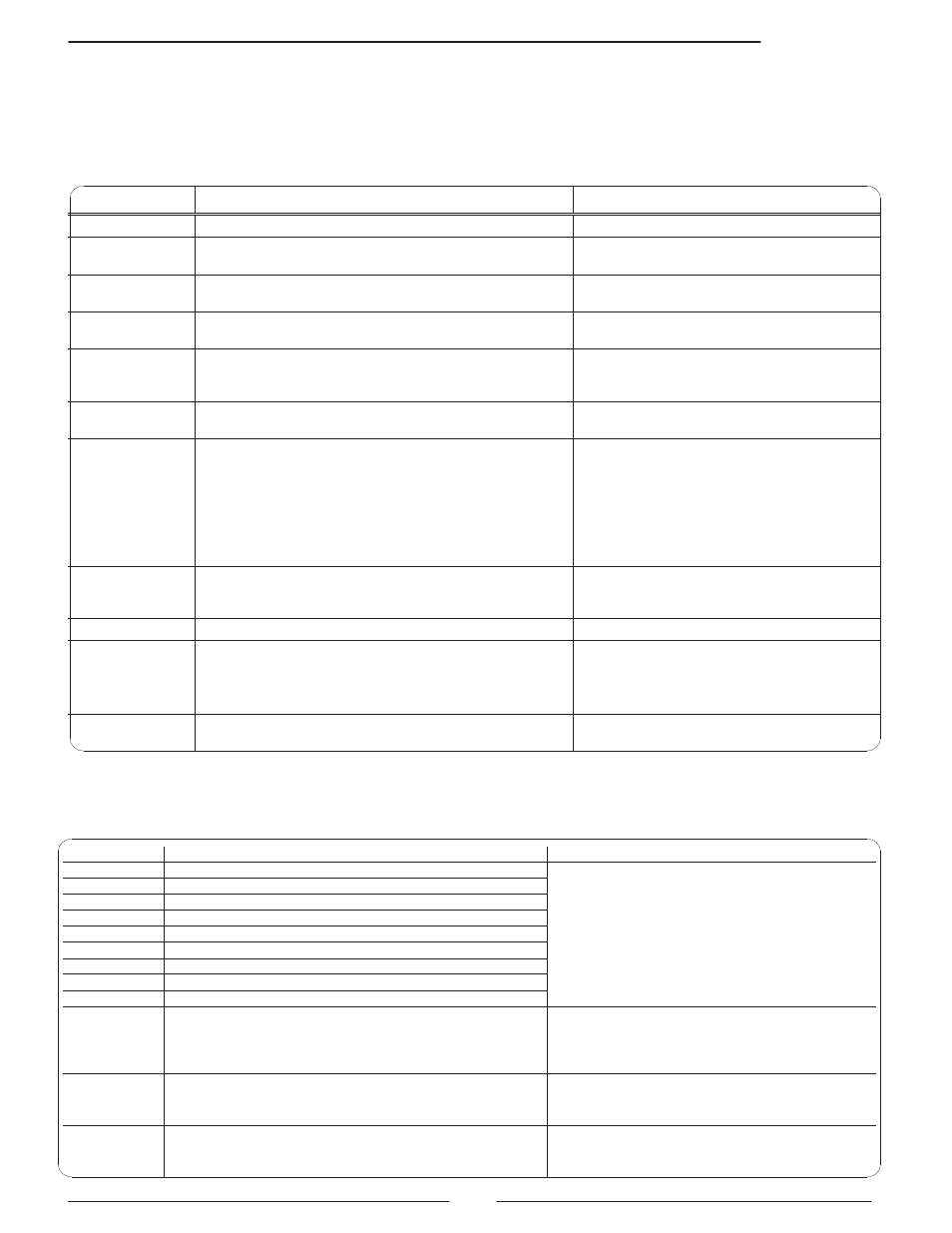

CODES

ANOMALIE DESCRIPTIONS

ACTION TO TAKE

0001

Problem with watch-dog circuit

ADDRESSING TO SERVICE

0002

Wrong configuration work data in eeprom

0004

Wrong configuration safety data in eeprom

0008

Defective eeprom

0010

Defective keyboard (one or more key are pushed during the test)

0020

Power supply voltage (+3.3) is out of range

0040

Power supply voltage (+13) is too low (<10V)

0080

Power supply voltage (+13) it’s too high (>14V)

0200

Timeout calibration input (input circuit is broken)

0400

Gain input stage is out of range

Check the status of the cables connecting the sensor to

the converter, the grounding connections of the devices

or the possible presence of strong and anomalous noise

sources

0800

Interruption on the coils circuit

Check the status of the cables connecting the sensor to

the converter

0C00

Cumulative alarm 0800 + 0400

See single codes 0800 and 0400 above.

ALARM MESSAGES

CAUSES AND ACTIONS TO BE TAKEN

ANOMALIES CODES

Messages

ANOMALIES

ACTION TO TAKE

NO ALARMS

All works regularly

-----

MAX ALARM

The flow rate is higher than the maximum threshold set

Check the maximum flow rate threshold set and the

process conditions

MIN ALARM

The flow rate is lower than the minimum threshold set

Check the minimum flow rate threshold set and the

process conditions

FLOW RATE >FS

The flow rate is higher than the full scale value set on the

instrument

Check the full scale value set on the instrument and

the process conditions

PULSE/FREQ>FS

The pulse generation output of the device is saturated

and cannot

generate

the sufficient number of impulses

Set a bigger unit of volume or, if the connected

counting device allows it, reduce the pulse duration

value

EMPTY PIPE

The measuring pipe is empty or the detection system has not

been properly calibrated

Check whether the pipe is empty or repeat the empty

pipe calibration procedure

BATCH ALARM

Batch interrupted for the followings condition:

Timer batch expired before the end of the batch

Batch valve open and flow rate to zero for a time longer

to the safety timer set

Batch valve closed and flow rate different from zero for

a time longer than the safety timer set

Verify:

Presetting

System conditions

INPUT NOISY

The measure is strongly effected by external noise or the cable

connecting the converter to the sensor is broken

Check the status of the cables connecting the sensor,

the grounding connections of the devices and the

possible presence of noise sources

EXCITATION FAIL The coils or the cable connecting the sensor are interrupted

Check the connecting cables to the sensor

CURR. LOOP

OPEN

The 4-20mA output on board or the optional one are not correctly

closed on a valid load

Verify the load is applied to the output (max 1000

ohm).

To disable the alarm,set the “mA V.fault” value

(menu alarm ) to 0.

P.SUPPLY FAIL

Power supply different from that indicated on the label.

Verify that the power supply is with in the

specifications indicated on the label