Grounding, Grounding the dms – Liquid Controls DMS Installation User Manual

Page 10

10

Grounding the dMs

After the DMS is mounted, you must ensure that the

DMS is properly grounded. Without a proper ground,

the DMS is susceptible to damage in the event of static

discharges and voltage spikes.

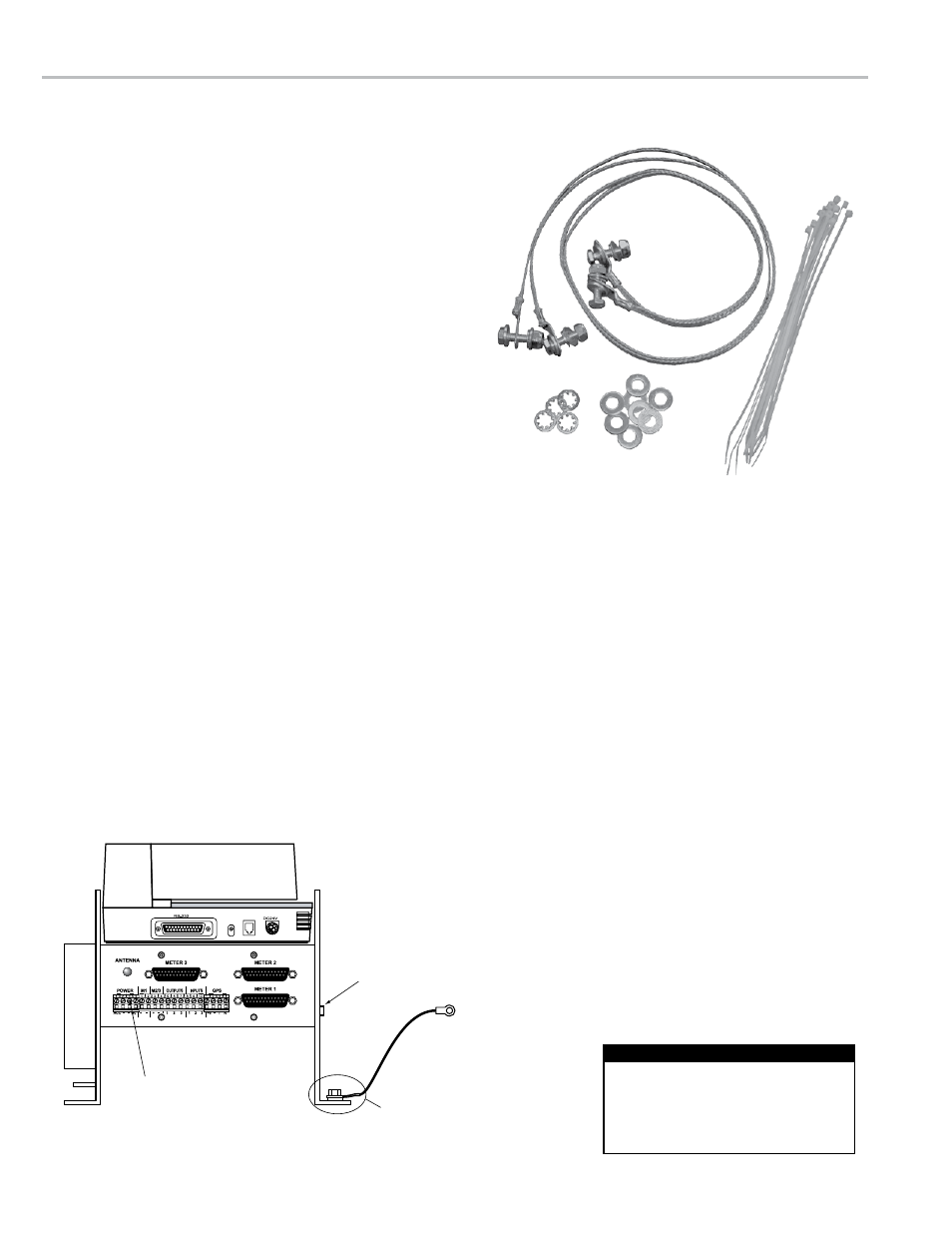

To protect the DMS, LC ships each unit with a ground

strap kit (82180). Each kit contains two ground straps.

One strap is for grounding the support brackets to the

chassis. The other strap grounds the seat to the chassis.

If the truck has two seats, both seats must be grounded.

An additional ground strap kit can be ordered from Liquid

Controls.

GroundInG The suPPorT braCkeTs

The DMS must be grounded to a good chassis ground.

In many cases, a good ground is established when the

support brackets are bolted to the chassis. Check for a

good chassis ground. If the ground is inadequate, attach

a ground strap to the support brackets.

Check for a good ground connection between the

dMs and the chassis:

1. Turn

OFF all accessories, including the dome light, to

prevent other currents from distorting the reading.

2. Take a multimeter and measure the resistance between

one of the silver, hex head screws on the support

brackets and the ground terminal of the DMS, pin 3 on

the power plug (see figure below).

a. If the resistance is less than 3Ω, the system is grounded

adequately.

b. If the resistance is greater than 3Ω, install a ground strap

between a support bracket and a clean ground point on

the cab chassis.

GroundInG

Ground a dMs support bracket to the cab chassis:

1. Find a suitable ground point, and bolt one ring terminal of the

ground strap to the chassis of the cab. An ideal grounding

point is clean, out of the way, and easily drilled and bolted.

2. Remove a mounting bolt from the support bracket.

3. Rebolt the support bracket to the cab chassis with the

ring terminal and a star washer. Place the star washer

directly onto the support bracket, and turn it into the

bracket until it penetrates the coat of paint.

4. Measure the resistance between the silver, hex head

screw and Pin 3 again.

5. If the resistance is still greater than 3Ω, check for proper

metal to metal contact on both ends of the grounding

strap. Clean any paint, dirt, or oxidation that may block

the grounding point. If the resistance remains above

3Ω, attach the ground strap to a different ground point.

Repeat the process until the ground resistance is below

3Ω.

Pin 3, Ground

Attach too

a good chassis

ground

Place a bolt and washer

on top of the ring terminal

and a star washer between

the ring terminal and the support bracket

Silver Hex

Head Screw

Ground Strap Kit

PN 82180

Check the ground connection

periodically. Connections can become

become susceptible to electrostatic

discharge over time due to corrosion

and gunk.

Check the Ground