Cashco C-CS User Manual

Page 4

4

IOM-C-CS

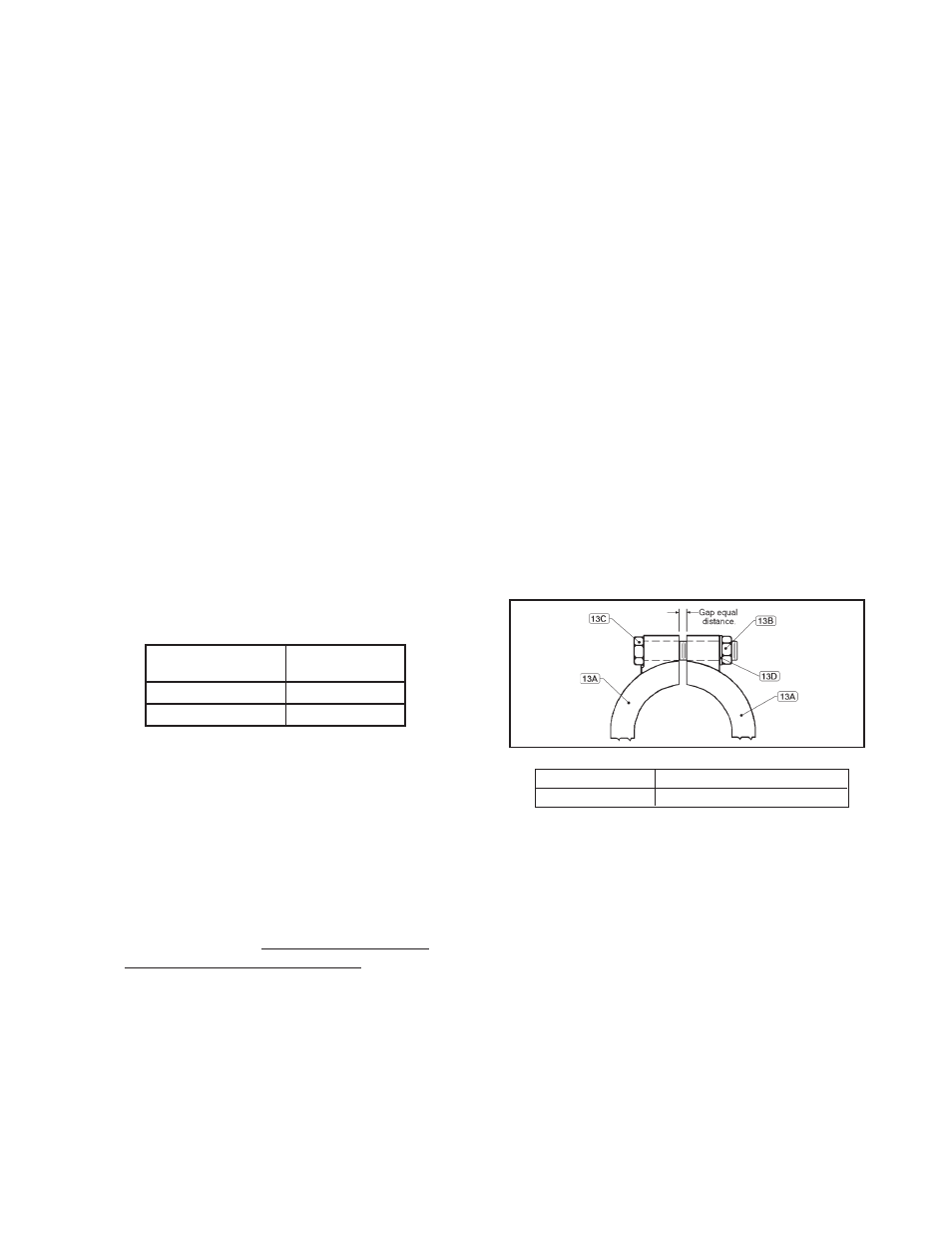

Figure 1: Clamp Arrangement.

together by hand. NOTE: Top of dowel

pin (25.8) should be fl ush with top surface

of adjusting screw cap (25.7).

22. Install new bearing (26) on top of upper

guide assembly (25).

23. Align slot guides inside spring chamber

(2) with spring button (4) tabs (ears) and

position on to body (1). Align with match

marks of step 6. previous.

24. Place handle (6) over end of guide post

(27) coming to rest on adjusting screw cap

(25.7). Insert hitch pin (21) into hole through

end of guide post (27). Apply Loctite 242

or equalivent to threads of set screw (30)

install into top of guide post (27) and tighten

securely.

25. Reposition clamps (13A) around body (1)

and spring chamber (2) fl anges. Insert clamp

bolts (13C), washers (13D) and tighten

clamp nuts (13B) in alternating pattern.

NOTE: Gap be tween clamp (13A) halves

should be equal in size. Gap and torque

re quire ments are as follows:

26. Reapply compression to the range spring

(7) by rotating handle (6) CW as per the

num ber of revolutions re cord ed in VI.B.2.

27. Return to Section II for Installation and

Sec tion IV for Start-up.

13. Clean gasket (15) and O-ring (16) retaining

surfaces of body (1) and spring chamber (2).

14. Clean all parts in accordance with Own er’s

cleaning procedures. Reposition plug (14)

back into vise with body (1). Ensure that the

plug (14) is in contact with the seating area of

the body (1) and the face of the inlet fl ange of

the body (1) is resting on the vise.

15. Place new diaphragm gasket (15) on body (1)

fl ange.

16. Install O-ring (16). NOTE: For Opt.-11 re po si-

tion push er plate (20) on threaded end of plug

(14) and install O-ring (18) and seal (19). Refer

to Figure 4.

17. Place diaphragm (17) over threaded end of

plug (14). NOTE: The word ‘TOP’ is etched on

one side of the diaphragm and should be vis-

ible when looking down on the diaphragm.

18. Place a small amount of medium strength

threadlocker equal to "Blue 242 Loctite" on

threaded end of plug (14). Reassemble pres-

sure plate assembly (27,28 and 29) to plug

(14). Refer to NOTE: in Step 10. Grasp the

parts and rotate pres sure plate assembly

(27,28,29) CW until wrench tight (met al-to-

metal con tact); Torque values not to ex ceed

the following:

19. Center/align the above pressure plate/

diaphragm assembly on the di a phragm (17)

fl ange sur face in the body (1).

20. Position spring (7) on to hub of pressure plate

(28). Place adjusting screw (25.6) - with spring

button (4) - over end of guide post (27) and

into spring (7) cav i ty. NOTE: Apply a small

amount of Emhart Bostik White Food Grade

“Never-Seez” or equiv a lent to threads of ad-

just ing screw (25.6) Do Not rotate adjusting

screw (25.6) or spring button (4).

21. Install new guide seals (25.9) in adjusting

screw cap (25.7). NOTE: There are two sizes

of u-cup seals - install the seal with the big-

ger diameter spring fi rst, open face into the

cap recess. Install the second u-cap seal,

open face exposed to face of adjusting screw

(25.6). Slide adjusting screw cap (25.7) over

end of guide post (27). Align dowel pin (25.8)

with hole in adjusting screw (25.6) and press

Body Size

in (DN)

Torque

in-lbs (N-m)

3/4"-1 1/2" (20-40)

100 (11)

2" - 3" (50-80)

270 (31)

Gap Torque

Equal Distance 225-250 in-lbs (25-28 N-m)