Cashco 1000 LP User Manual

Page 7

IOM-1000LP-Basic

7

c. Flow induced wear at expansion zone

where fl uid turns to enter the piston (24)

center.

d. Where the piston (24) ribbed guides

bear (guide zone).

If wear is signifi cant at any of these points,

both cylinder sub-assembly (21) and piston

sub-assembly (24 or 24, 25 and 26) should

be replaced. (Cashco, Inc., does not rec om -

mend attempting to replace the valve seat

(21.2) by pressing out and then re-pressing

in. Cashco, Inc., also recom mends that a

cyl in der (21) and piston (24 or 24, 25 and

26) be replaced as a set. Composition seat

discs (25) may be re placed individually.)

5. If a composition (soft) seat trim design is

uti lized, use the following sub-steps:

a. Tighten the “fl ats” of the seat disc screw

(26) within a vise. Firmly hand-grip the

piston (24) and turn CCW to loosen the

seat disc screw (26). If too tight, place a

screwdriver or similar rod within the pis-

ton (24) port holes and rotate. Re move

the piston (24), and inspect for raised

burrs around the port holes if a device

is used to loosen; deburr as re quired.

NOTE: Do not grip the piston (24) with

a wrench.

b. Remove the seat disc (25) and clean

the re cessed piston (24) area where the

seat disc (25) is placed. If the edges

which form the recess of the piston (24)

are worn, also replace piston (24) and

seat disc screw (26).

c. Place seat disc (25) into recessed end

of piston (24).

d. Place thread sealant on threaded por-

tion of seat disc screw (26), and manu-

ally ro tate piston (24) into seat disc

screw (26) (still fi xed in vise) to secure

seat disc (25). Tight en seat disc screw

(26) fi rmly. Do not over-tighten to the

point of em bed ding the seat disc screw

(26) into the seat disc (25); the seat disc

(25) should lay fl at with no rounded sur-

face. A mech anical aid is nor mal ly not

required; hand-tightening is nor mal ly

suf fi cient.

6. If utilized, place piston spring (30) over

small er end of cylinder (21).

7. Insert piston assembly (24 metal seat; 24,

25 and 26 comp. seat) into end of cylinder

(21).

8. Place piston collar (23) over end of piston

(24), ensuring that the spherical surface of

the piston (24) and the piston collar (23) bear

against each other.

9. Clean the body (1) cavity thru the openings.

Clean the “jet area” just inside the body (1)

outlet end thru which the piston (24) proj-

ects. Clean all parts to be reused. NOTE:

On valves originally sup plied with Option

1000-55, “ox y gen clean”, main te nance

must in clude a level of clean li ness equal to

Cashco, Inc's., cleaning standard #S-1134.

Contact factory for details.

10. Use special care cleaning the fl at mating

sur fac es of the body (1) and cylinder (21)

shoulder, as this pressurized joint is metal-

to-metal with no gasket.

11. Lubricate the cylinder (21) threads lightly

with thread sealant. Insert the entire trim

stack into the body (1) opening and thread

until tightly seated. NOTE: Take special

pre cau tion to keep piston collar from getting

“cocked” at an angle when inserted. Impact

until the cylinder (21) shoulder is metal-to-

metal with the body (1).

12. Inspect the body (1) outlet end to ensure that

the piston (24) is concentric to the body (1)

bore in the jet area and has clearance on

all sides. Under no conditions should the

piston (24) be touch ing the body (1). Use

two pencils or similar shafts to place in inlet

and outlet ends of valve and alternately push

on each end of the piston (24) to ensure

free movement. NOTE: Total move ment is

ap prox i mate ly 1/8" (3.2 mm).

13. Bench test unit for suitable operation and

seat leakage. NOTE: Regulators are not

nor mal ly tight shutoff devices. Pressure

must build above setpoint for best shutoff.

14. Spray liquid leak detector around cyl in der

(21)-to-body (1) connection and check for

leak age. Test pres sure should be a min-

i mum of 100 psig (6.9 Barg) at the inlet, or

actual service con di tions if high er.

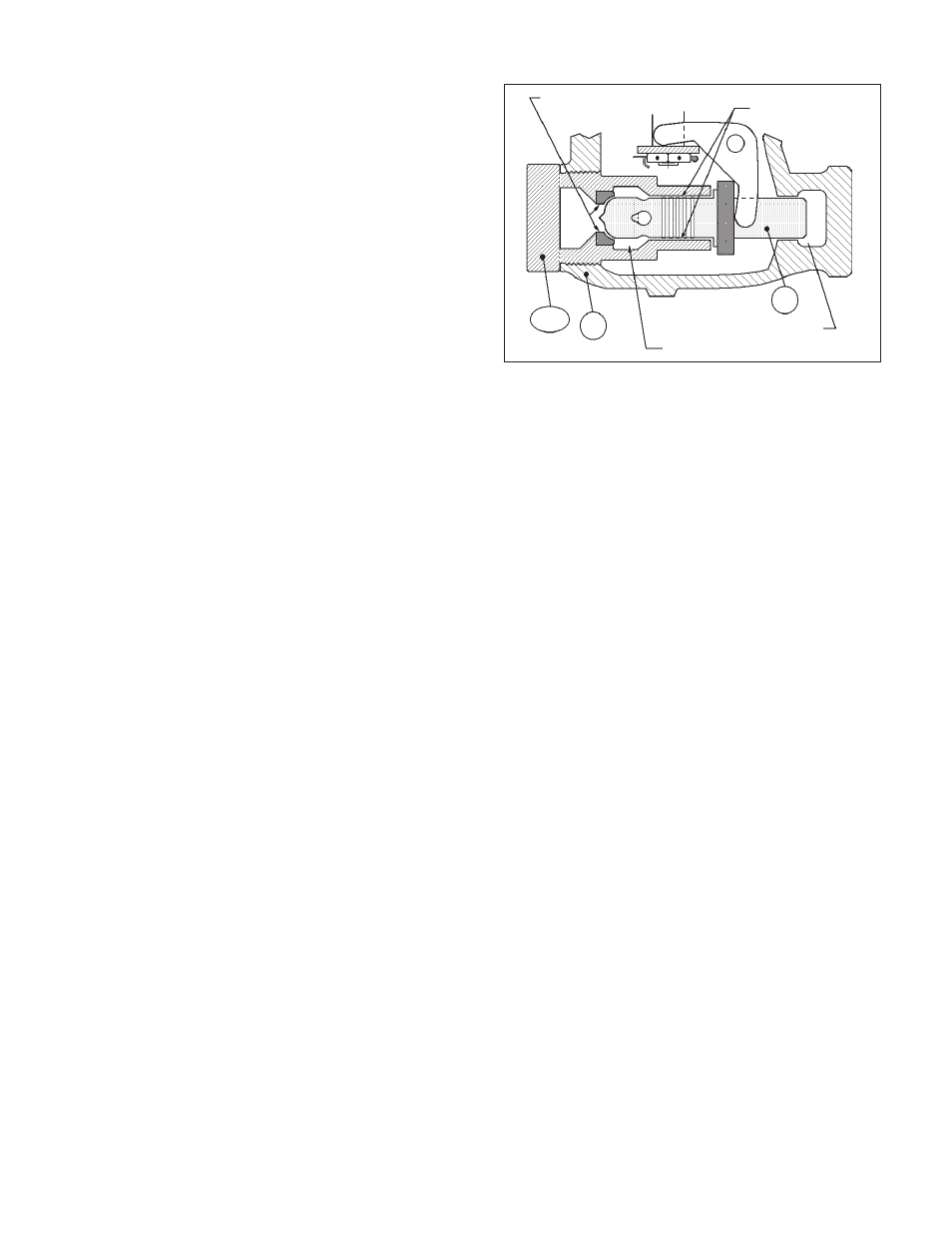

Cylinder Sub-Assembly (21) with Piston (24) Metal

Seat Construction

Jet Zone (E.10)

(21.2) Pressed In Seat Ring (E.5 b)

4

Guide Zone (E.5 d)

1

21.1

Expansion Zone (E.15 c)