Cashco 1000 LP User Manual

Page 5

IOM-1000LP-Basic

5

Body Size

Metal Diaphragm

Comp. Diaphragm

1/2"

35-40 ft. lbs.

25-30 ft. lbs.

3/4"-1"

45-50 ft. lbs.

35-40 ft. lbs.

DN 15

47-54 N-m.

34-41 N-m.

DN20-DN25

61-68 N-m

47-54 N-m

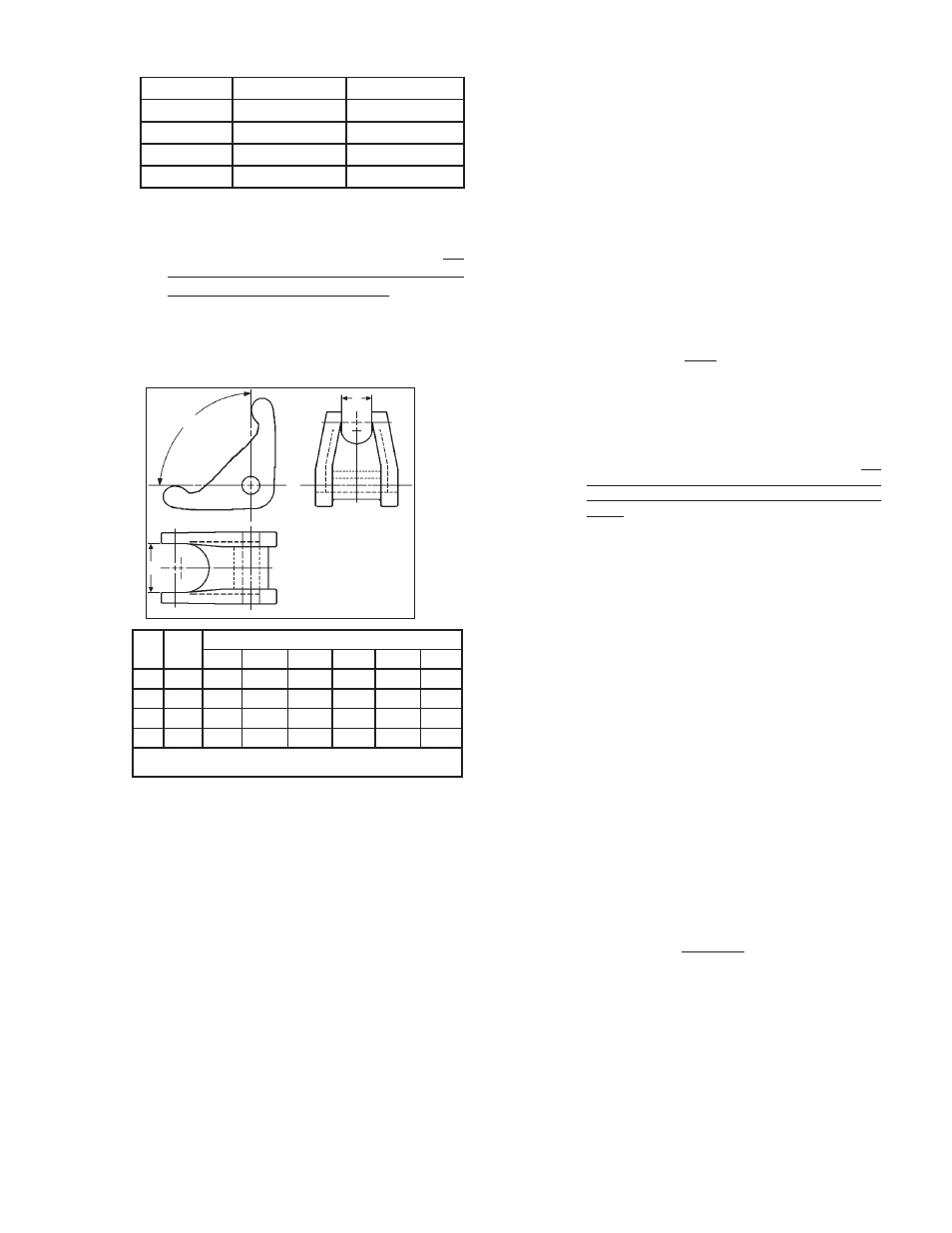

17. Remove cotter pin (15) se cur ing stud nut

(10) to lower end of pusher plate and stud

(13), and replace with a new pin (15). (Do

not allow the stud nut (10) to rotate when

the cotter pin (15) is re moved.)

18. Remove rocker arm shaft (17) and rocker

arm (14). Measure inside of rocker arm (14)

“prongs” as indicated below:

pres sion. It may also adversely change the

di a phragm setting, which will affect the unit's

per for mance, i.e. Option-45, non-as bes tos

construction utilizes special gaskets.

21. Using small gauge wire approximately 18"

(500 mm) long. Form a hook and place the

hook over one prong of the rocker arm (14).

Rotate the rocker arm (14) up until slack is

removed in the mechanism. Hold the wire

above the body (1) fl ange on the outlet side

of the valve.

22. Take the diaphragm sub-assembly (Step 16)

and lower it down into the body (1) cavity

off-center approximately 3/4"-1" (20-25 mm)

towards the inlet side of the valve. When

fully low ered, slide the di a phragm sub-as-

sem bly horizontally to wards the valve's

out let. The wire of Step 21 should hold the

rocker arm (14) up to allow the pusher plate

(5) and stud (13) (with stud nut (10) and stud

collar (16)), to slide underneath the rocker

arm (14) prongs. The rocker arm (14) prongs

must rest di rect ly on the stud collar (16). (Do

not allow the rocker arm (14) prongs to rest

between the stud nut (10) and the stud collar

(16).) Pull fi rmly to remove wire.

23. Align diaphragm (20) bolt holes with body

(1) fl ange bolt holes. Set range spring (27)

onto pressure plate (3), place spring but-

ton (4) on top of range spring (27). Place

multi-pur pose, high temperature grease into

de pres sion of spring button (4).

24. Aligning the matchmarks, place spring

cham ber (2) over the above stacked parts.

Install all bolts (8), nuts (9) and name plate

(28). Tight en bolt ing (8 and 9) in a cross

pattern that allows the spring cham ber (2)

to be pulled down even ly. Rec om mend ed

torque values* are as follows: All sizes

and di a phragms: 35 Ft-lbs (47 N-m)

25. Reinstall

ad

just ing screw (6) with lock nut

(7). Install closing cap (31) if pro vid ed.

26. Spray liquid leak detector to test for leak age

around bolt ing (8 and 9), body (1) and spring

cham ber (2) fl anges, and cyl in der (21) to

body (1) joint. Ensure that an outlet pressure

is main tained during this leak test of at least

mid-range spring level; i.e. 15-30 psig (1.0-

2.1 Barg) range spring, 23 psig (1.6 Barg)

test pres sure min i mum. Use 100 psig (7.0

* Minimum recommended torque values regardless of

gas ket ma te ri als. Some gasket materials may require

higher bolt torques to obtain adequate seal.

Gasket

ma

te ri al may take a “set” with time; a re check

of torque values should be made if the unit has been

stored on the shelf for over 30 days.

NOTE:

Never replace bolting (8 and 9) with

just any bolting if lost. Bolt heads and nuts are

marked with specifi cation iden ti fi ca tion num bers.

Use only proper grades as re placements.

"

A

"

90°

"

B

"

DIM

MAT'L

Valve Size

1/2"

DN15

3/4"

DN20

1"

DN25

A

BRZ

7/8"

22 mm

1-5/32"

29 mm

1-7/16"

37 mm

B

BRZ

5/8"

16 mm

25/32"

20 mm

3/4"

20 mm

A

SST

13/16"

21 mm

1-1/16"

27 mm

1-7/16"

37 mm

B

SST

9/16"

14 mm

23/32"

18 mm

3/4"

20 mm

If any of the above dimensions are exceeded by 1/8" (3 mm), replace rocker

arm (14)

19. Check rocker arm shaft (17) for wear and

straightness. Replace if damaged. Rein-

stall in body (1) thru rocker arm (14). Apply

thread sealant to the rocker arm shaft (17)

threads prior to tightening. Make sure that

the rocker arm shaft (17) enters the sup-

port slot op po site the threaded open ing and

does not align crooked or re strained from

full thread en gage ment with the body (1).

Make sure the rocker arm (14) prongs that

strad dle the piston (24) hold the piston collar

(23) against the piston (24). Do not allow the

rocker arm (14) prongs to push directly on

the piston (24).

20. Clean the body (1) diaphragm fl ange. Install

a new diaphragm gasket (19). Composition

(soft) diaphragms require no diaphragm

gas ket. NOTE:

Use only gaskets man u fac-

tured by Cashco, Inc. that are of the same

ma te ri al as those originally supplied. Sub-

sti tu tion may cause improper gasket com-