Cashco 1000 LP User Manual

Page 4

IOM-1000LP-Basic

4

Diaphragm sub-assembly consists of items (10), (11),

(12), (13), (15), (16) and (20). (Metal diaphragm de-

sign).

4. Regulators originally supplied as “oxygen

cleaned” (Option-55 ) are assembled using

special gasket sealant, Fluorolube GR-362

1

, or equivalent. Cashco, Inc. rec om mends

following factory cleaning spec ifi cation #S-

1134, or equiv a lent. Con tact factory for

details.

B. Diaphragm Replacement:

1. Securely install the body (1) in a vise with

the spring chamber (2) directed up wards.

2. Remove closing cap (31) if provided. Relax

range spring (27) by turning adjusting screw

(6) CCW until removed from spring chamber

(2).

3. Paint or embed a match mark between body

casting (1) and spring chamber casting (2)

along fl anged area.

4. Remove all diaphragm nuts (9) and bolts (8).

Remove nameplate (28).

5. Remove spring chamber (2), range spring

(27) and spring button (4).

6. Pry up the diaphragm(s) (20) and diaph ragm

gasket (19) around the perimeter of the body

(1) diaphragm fl ange to ensure that the

diaphragm(s) (20) are not “sticking”. NOTE:

Diaphragm gasket (19) is not used with a

com po si tion (soft) diaphragm.

7. Remove the diaphragm sub-assembly by

slid ing the pusher plate and stud (13) and

nut (11) in the direction of the regulator's

inlet, ap prox i mate ly 1/2"-3/4" (12-20 mm).

The push er plate and stud (13), stud nut

(10), and stud collar (16) should disengage

from the rock er arm (14) slot. Lift vertically

for the diaphragm sub-assembly re mov al.

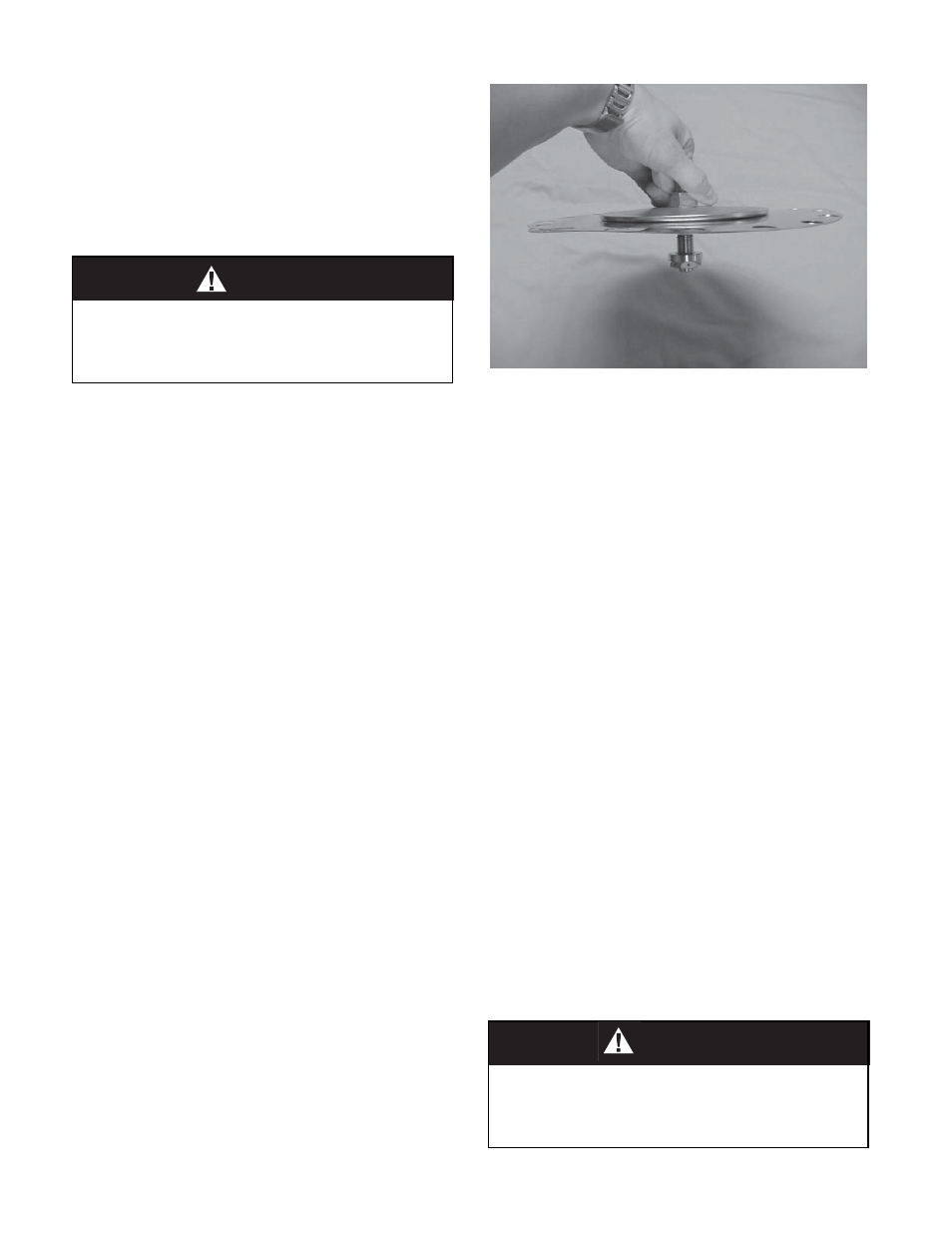

8. Place the pusher plate and stud (13) in a

sepa rate vise, gripping the stud (13) on the

hex ago nal cast-in-place edges located on

the un der neath side of the pusher plate stud.

NOTE: Do not remove the stud nut (10),

stud collar (16), or cotter pin (15). Loosen

and remove pressure plate nut (11).

9. Remove pressure plate (3) by lifting.

10. Pry loose pusher plate and stud (13) from

diaphragm(s) (20) or from pusher plate gas-

ket (12). (Pusher plate gasket (12) is not

used with a composition (soft) diaph ragm.)

Remove the diaphragm(s) (20).

11. Remove pusher plate gasket (12) from

push er plate and stud (13).

12. Clean gasket sealing surface of pusher plate

and stud (13) thoroughly.

13. Install new pusher plate gasket (12), if re-

quired, over pusher plate and stud (13).

14. Install new diaphragm(s) (20) over pusher

plate and stud (13). NOTE: Refer to the

quantity of diaphragms (20) incorporated

per the bill of materials listing. Depending

on outlet pressure level, various quantities

of metal diaphragms will be “stacked”.

15. Inspect pressure plate (3) to ensure no

de for ma tion due to over-pressurization. If

de formed, bent, or otherwise distorted, re-

place.

16. Ensuring that the fl at side of the pressure

plate (3) rests against the dia phragm (20).

Place the pressure plate (3) over the pusher

plate and stud (13). Install pressure plate

nut (11) onto the stud (13) and tighten. Rec-

om mend ed torque val ues are as follows:

WARNING 2

1

Product of Fisher Scientifi c Com pa ny

DO NOT USE FIN GERS TO HOLD DIAPHRAGMS

(20) DURING TIGHT EN ING OF NUT (11). Use two

fl ange bolts (8) to keep multiple di a phragms' (20)

properly aligned with bolt holes while tight en ing the

stud nut (10).

CAUTION E

SYSTEM UNDER COMPRESSION.

Prior to removing fl ange bolts, relieve spring

compression by backing out the adjusting screw.

Failure to do so may result in fl ying parts that

could cause personal injury.