Cashco 1000 LP User Manual

Page 6

IOM-1000LP-Basic

6

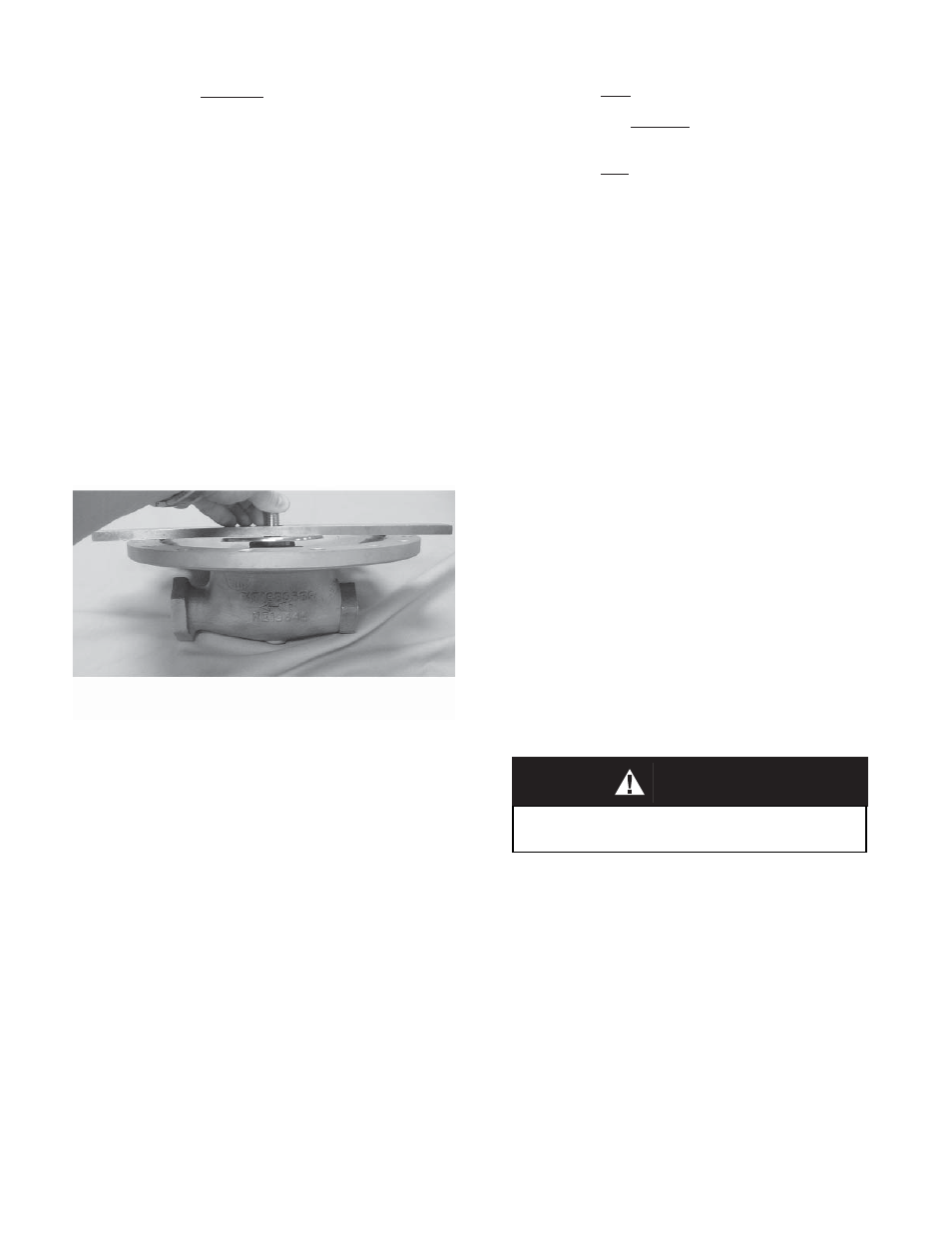

Checking diaphragm setting.

Barg) min i mum inlet pres sure to leak test.

Actual service con ditions should be used if

in ex cess of the minimum con di tions.

C. Special Instructions for Diaphragm

Removal.

1. If Option-3, Handwheel, is uti lized, the

ad just ing screw (6) and locknut (7) are

re placed by a handwheel (6.3)/adjusting

screw (6) assembly and locking le ver (7).

2. Use only gaskets of the same material as

original equipment. Cashco's Option-45,

non-as bes tos con struc tion, uti liz es spe cial

gas kets.

D. Diaphragm Setting Adjustment:

1. In the previous “Sub-Section B. Diaph ragm

Replace ment”, care was taken to prevent

re mov al of the stud collar (16) and stud nut

(10). Location of the stud nut (10) is a critical

ad just ment for a Model 1000 regulator.

2. Not removing the stud nut (10) will provide

per for mance equal to original factory per for-

over 0.020" (0.50 mm).

b. Diaphragm setting acceptable. Bar

lifts be tween 0.010"-0.020" (0.25-0.50

mm).

c. Diaphragm setting too low. Bar lifted

less than 0.010" (0.25 mm), or failed to

be lifted.

4. The castle style stud nut (10) has six lo ca -

tions per revolution to align the stud nut (10)

slots with the drilled hole thru the pusher

plate and stud (13). Each stud nut (10) slot

represents a movement up/down of 0.010"

(0.25 mm). NOTE: The ideal diaphragm

set ting is 0.015" (0.38 mm) high, and bet-

ter per for mance is usu al ly obtained when

the di a phragm is slight ly higher rather than

low er. As the measuring of thou sandths of

an inch is dif fi cult with such a procedure, it

is rec om mended that the “null” position be

found where the di a phragm (20) is fl ush

with the body (1) fl ange (bar ap prox i mate ly

at 0.000" (0.00 mm)). Remove the push er

plate and stud (13), rotate the stud nut (10)

one or two slots CCW to bring the setting to

0.010"-0.020" (0.25-0.50 mm) high.

5. Place cotter pin (15) thru the slot/hole, bend

over ends.

6. Continue re-assembly per Sub-Section B.

Di a phragm Replacement, Step 14.

E. Trim Removal and Replacement

1. Install body (1) horizontally in a vise with the

spring chamber (2) directed upwards, and

the body (1) held at the outlet end.

2. Loosen and remove the cylinder (21) by

turning CCW. NOTE: The piston (24) and

piston collar (23) should come out with the

cylinder (21) re mov al.

3. If an Option-17 piston spring (30) is utilized,

it also should be removed and re placed at

trim replacement.

4. Inspect inside surface of cylinder (21) at four

points:

a. Valve seat (21.2). Check for ero sion/

wear on seat ing surfaces. If wear is

ex ces sive, con sider uti liz ing Op tion

1000-15, stel lited seat sur faces.

b. Seat (21.2). Check for wire drawing

be tween cyl in der (21.1) and valve seat

(21.2) where pressed in. If wear exists

here, an Option-14, integral seat, should

be uti lized as a re place ment.

CAUTION F

m ance when a diaphragm(s) (20) is re placed

with a like diaphragm(s) (20). How ever, if

the stud nut (10) is removed, or a switch is

made from metal to composition diaphragm

(20), or vice versa, the dia phragm setting

should be checked.

3. Follow procedure “Sub-Section B. Dia-

phragm Re place ment” to the point of re mov-

ing diaphragm(s) (20), Step 14. Remove

di a phragm gasket (19) and pusher plate

stud gas ket (12). Obtain a fl at 12" x 1-1/2"

x 1/4" (300 mm x 40 mm x 6 mm) plate bar

with a 3/4" (20 mm) hole drilled in the cen-

ter. Hook the pusher plate and stud (13)

into the rocker arm (14) prongs prop er ly.

Pull fi rmly up on the pusher plate and stud

(13) to ensure that all slack is re moved from

the mech a nism and that the piston (24) is

seat ed fi rmly. Relax the pulling and place

the fl at bar over the pusher plate and stud

(13) with the stud (13) passing thru the hole

of the bar. Again, pull fi rmly up to remove

mech a nism slack. One of three positions

will be reached:

a. Diaphragm setting too high. Pusher

plate and stud (13) will lift the fl at bar

Do not allow the pis ton (24) to fall from within the

cylinder (21); tip cylinder with hex end down.