Cashco 9540R P/P User Manual

Page 5

IOM-9540R

5

four cap screws (79). The bracket should end

up with four holes to mount the positioner unit

and its baseplate (26) as shown in Figure 2.8.

7.

Attach the baseplate and mounting bracket

(76) assembly to housing cover (13) using

four cap screws (78). Align baseplate (26) to

be parallel with bottom of valve's arm housing

(4). See III.C. NOTE:

Engage the tongue-

and-groove joint between the positioner

baseplate rotary shaft (32) and the spacer

(17) with its protruding set screw (77).

8.

Determine characterization cam's (24) proper

orientation as indicated in Figures 8 thru 15;

cut a spacer from wood or heavy cardboard to

the dimension “X” indicated.

NOTE:

Whether air-to-open (ATO) or air-to-

close (ATC), Cashco's Ranger QCT, Premier

(unlined) or Premier EZO all rotate clockwise

(CW) to “close” valve, or counter clockwise

(CCW) to “open” valve, when viewed from

stem (7) end.

9.

Place a thin film of adhesive, glue or pipe

thread sealant on the “back” side of cam (24)

to secure toothed lock washer (28) to cam

(24). Use post end screw (23) to correctly

align centers of these three parts (24, 27 &

28); do not allow the post-end screw (23) to

adhere to these parts.

10. Using the spacer of Step 8., position cam (24)

with adhered parts (27 & 28) up to the end of

positioner rotary shaft (32). Carefully screw-in

post-end screw (23) while holding cam (24) in

its approximate position. Hand-tighten post-

end screw (23) until certain that the washers

(27 & 28) have remained in alignment. (If

washers (27 & 28) are misaligned, the cam

(24) will not be able to be secured.)

11. Using the spacer of Step 6. above, wrench-

tighten post-end screw (23) into a preliminary

position.

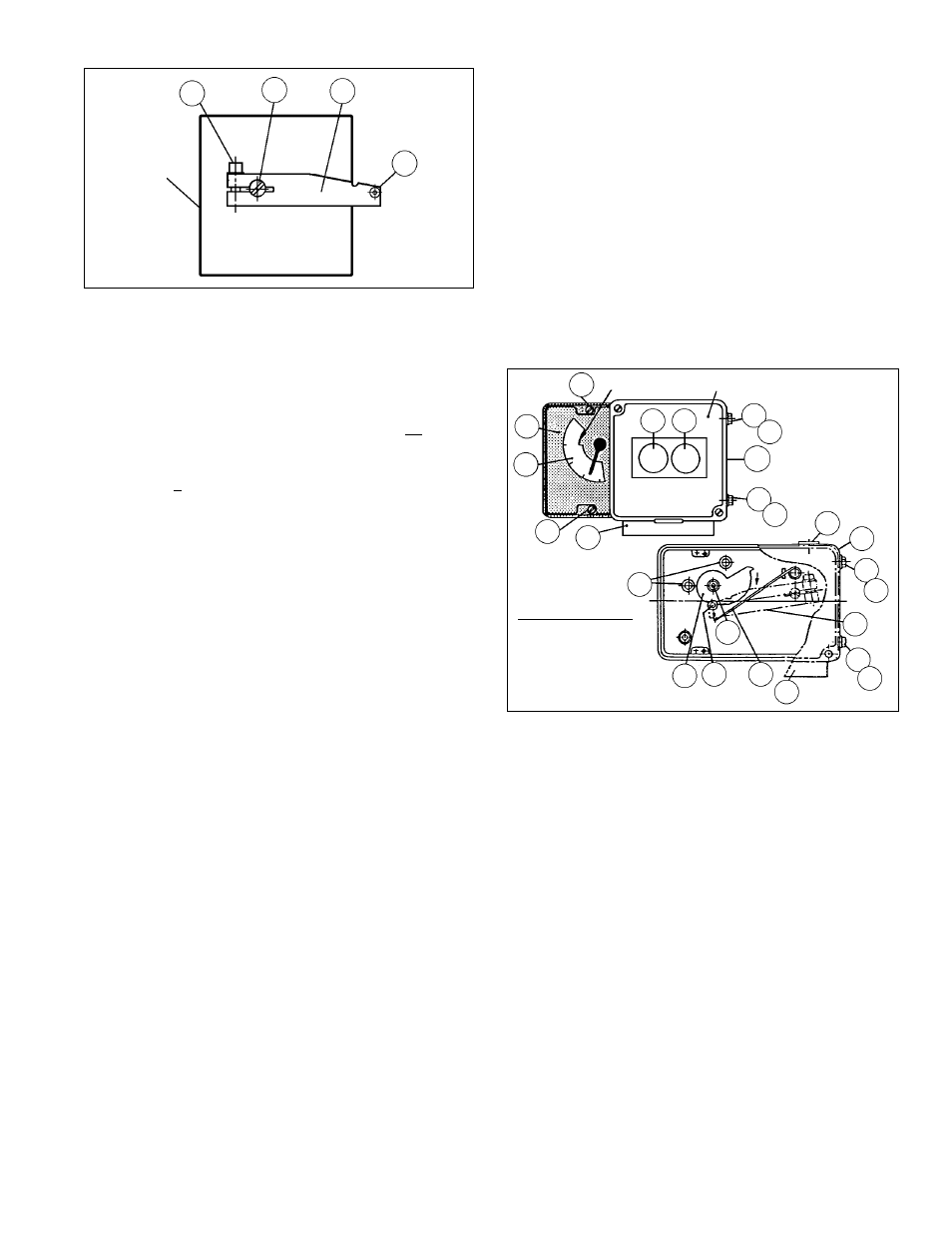

Figure 4 - Rear View

Main

Positioner

Unit

21

17

13

31

12. As shown in Figure 4, attach the feedback lever

(13) onto the positioner unit’s main shaft (17) by

hand-tightening socket cap screw (21). DO

NOT WRENCH TIGHTEN SCREW (21).

13. Remove the two plastic screws in the right side

of the main positioner unit where cap screws

(11) would be inserted. (See Figure 5.)

14. Begin to set the main positioner unit near its

final position on baseplate (26). Using needle

nose pliers grasp compensating spring (18)

and “hook” the end of the spring (18) under the

lower side of the feedback lever as indicated

in Figure 5.

Figure 5

A3

11

12

WC

11

12

G2

G1

22

DC

A3

AB

33

26

11

12

13

11

12

AB

18

17

31

24

A1

"Notch"

Main Positioner

Unit

15. Position the positioner unit onto baseplate

(26), ensuring that the feedback lever’s (13)

roller is placed into contact with characteriza-

tion cam (24) into the approximately proper

location. (See Figures 8 thru 15.)

16. Fasten the positioner unit to the baseplate

(26) inserting two cap screws (11) with lock

washers (12) thru the side of baseplate (26).

17. Remove the positioner cover (WC). Remove

plastic plug (33) from the upper edge of base-

plate (26), allowing access to the socket cap

screw (21).

18. Press the stroke factor lever (19) (See Figure

6) of the positioner’s internals against the

travel stop pin (20) and hold firmly in place.

Using the #5 Allen wrench provided, tighten

socket cap screw (21) to the main shaft (17)

while holding the stroke factor lever (19).

Replace plastic plug (33).

G2 = Air Supply "IAS"

G3 = Output "LOAD"

Illustrated Position:

Ait to Close

Fail Open