Cashco 9540R P/P User Manual

Page 13

IOM-9540R

13

4.

The following procedure must be observed in

order to achieve a no-feedback adjustment of

the ZERO and STROKE setting.

a.

Press the stroke factor lever (19) against

the travel stop pin (20).

b.

Set the stroke factor thumbscrew (40) to

a high stroke factor (approximately 5/64”

before the upper stop).

c.

Turn the zero thumbscrew (39) until the

output pressure is mid-range of “SIG”

span and make a note of this value.

d.

Set the stroke factor thumbscrew (40)

to a low stroke factor (approximately

5/64” before the lower stop). The output

pressure may not vary by more than

±

0.003 psig as compared with the setting

described in c. above.

e.

In case of excessive deviations, the travel

stop pin (20) should be adjusted. When-

ever the travel stop pin (20) is adjusted,

the settings described in b. to d. should be

repeated until the deviation is less than

±

0.003 psig.

f.

Seal the travel stop pin (20) with sealing

paint.

5.

Return the changeover plate (15) to its origi-

nal positioner if it was “U”. Re-tighten the

feedback (13) lever onto the main shaft (17) of

the positioner (see Section III.D.8. & 9.).

6.

Go thru a complete calibration/adjustment

procedure as described in Section V.

B. Cleaning the Throttle Screw: (See Figure 18)

1.

Unscrew CCW the limiting screw (43). If you

can’t pull it out by hand, unscrew CCW the

throttle screw (42) and remove both by hand.

2.

Pull the throttle screw (42) out of the limiting

screw (43).

3.

Place the throttle screw (42) in solvent (e.g.

benzene) and blow through it carefully. It is

best to clean in an ultrasonic solvent bath.

4.

Turn the throttle screw (42) in again as far as

it goes CW.

5.

Turn the limiting screw (43) in as far as it goes

CW; then back it out CCW about half a revo-

lution.

6.

Secure the limiting screw (43) with sealing

paint.

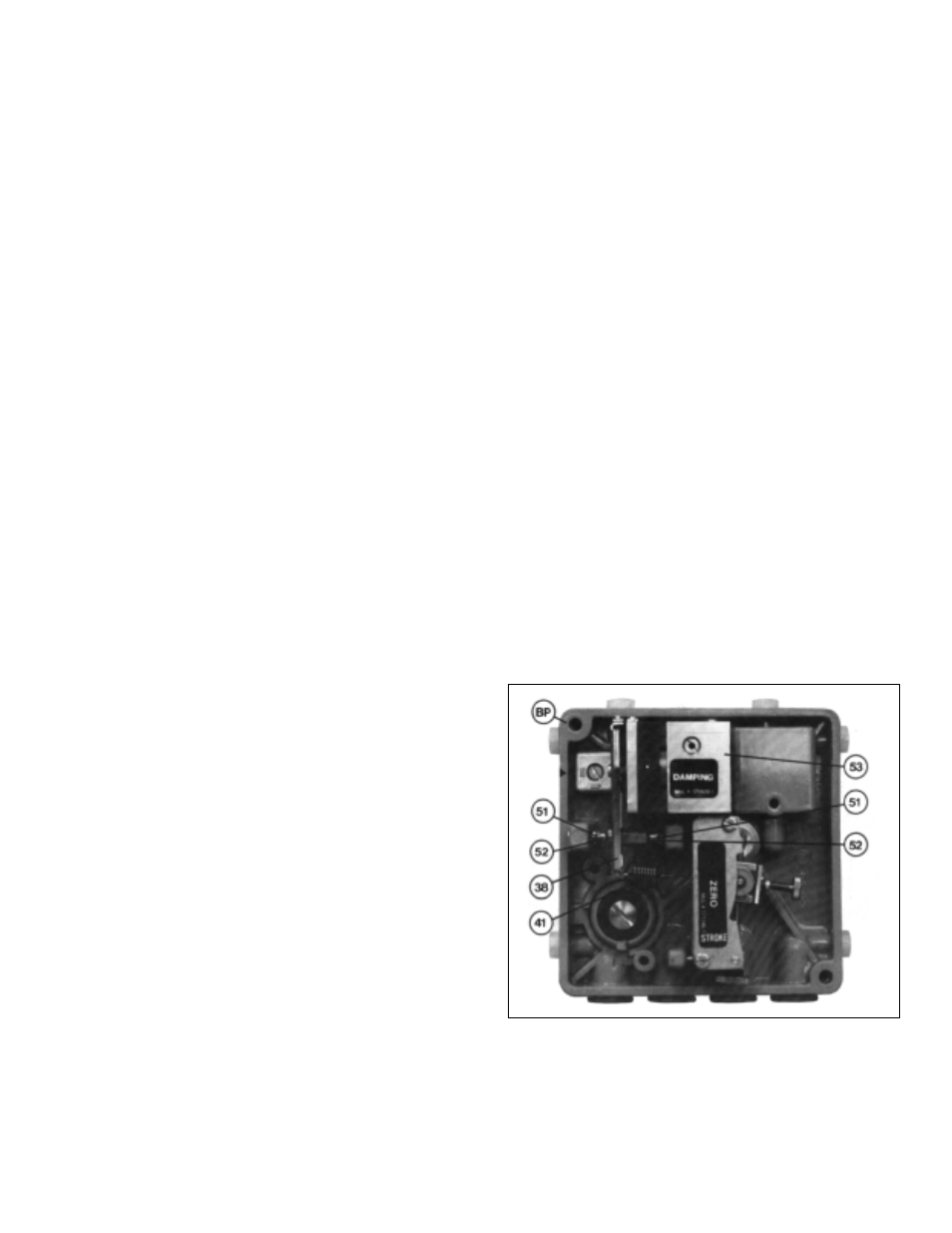

C. Replacing the Amplifier: (See Figure 21)

1.

Unhook the range spring (41) from the flapper

lever (38).

2.

Unscrew and remove the amplifier (53) sub-

assembly; the two amplifier mounting screws

are accessible from the rear of the positioner.

3.

Install a new amplifier (53). Do not forget the

O-rings between the amplifier and the base-

plate (BP) (air baffle). Before tightening, care-

fully align the mounting screws, position the

amplifier (53) in such a way that the flappers

(52) are concentrically aligned with the nozzles

(51).

4.

Hook the range spring (41) onto the flapper

lever (38).

5.

Perform a maintenance basic adjustment and

recalibrate per Section IV, V and VI.

Figure 21