Cashco 9540R P/P User Manual

Page 3

IOM-9540R

3

D. Existing Control Valve Modifications:

1.

Refer to IOM-48 or IOM-148 for instructions

for the rotary actuators used on Ranger QCT,

Premier EZO and Premier (unlined).

2.

All indicated Item Numbers that are with

respect to IOM-48 or IOM-148 will be in paren-

thesis and underscored; i.e. (32). All part Item

Numbers that are with respect to this

IOM-9520R are not underscored; i.e. (32).

NOTE:

If no handwheel (58) or adjusting screw

assembly is provided with the actuator, it is

recommended that the rod end (9) be un-

coupled from the arms (5) by removal of bolt

(40). See IOM-48 or IOM-148. Use of air

loading into the actuator casing (1) is pos-

sible, but introduces safety considerations;

i.e. use “tools” and not “fingers” inside the arm

housing (4) area.

3.

Remove cover plate (20).

4.

Steps to change the mounting and stem inter-

connection between the valve end-of-shaft

and the positioner unit. These changes bring

the positioner into compliance with NAMUR

Standard VDI/VDE #3845.

#48 Actuator: (See Figure 3)

a.

Turn actuator handwheel CW to remove

stem windup torque. The linkage from the

actuator stem (9) will become slack. May

require 1-3 revolutions. This will ease

removal of cap screws (31).

b.

Remove three cap screws (31), dial lens

(14), travel indicator dial (15), cover plate

(13), cap screw (32), travel indicator (16),

lock washer (55) and pin (51). Remove

bearing (18), both bearing flanges (19)

and indicator spacer (17).

c.

Discard removed dial lens (14), travel

indicator dial (15), cap screw (32), travel

indicator (16), washer (55), pin (51) and

indicator spacer (17). Save only cover

plate (13), bearing (18) and both bearing

flanges (19) for re-use.

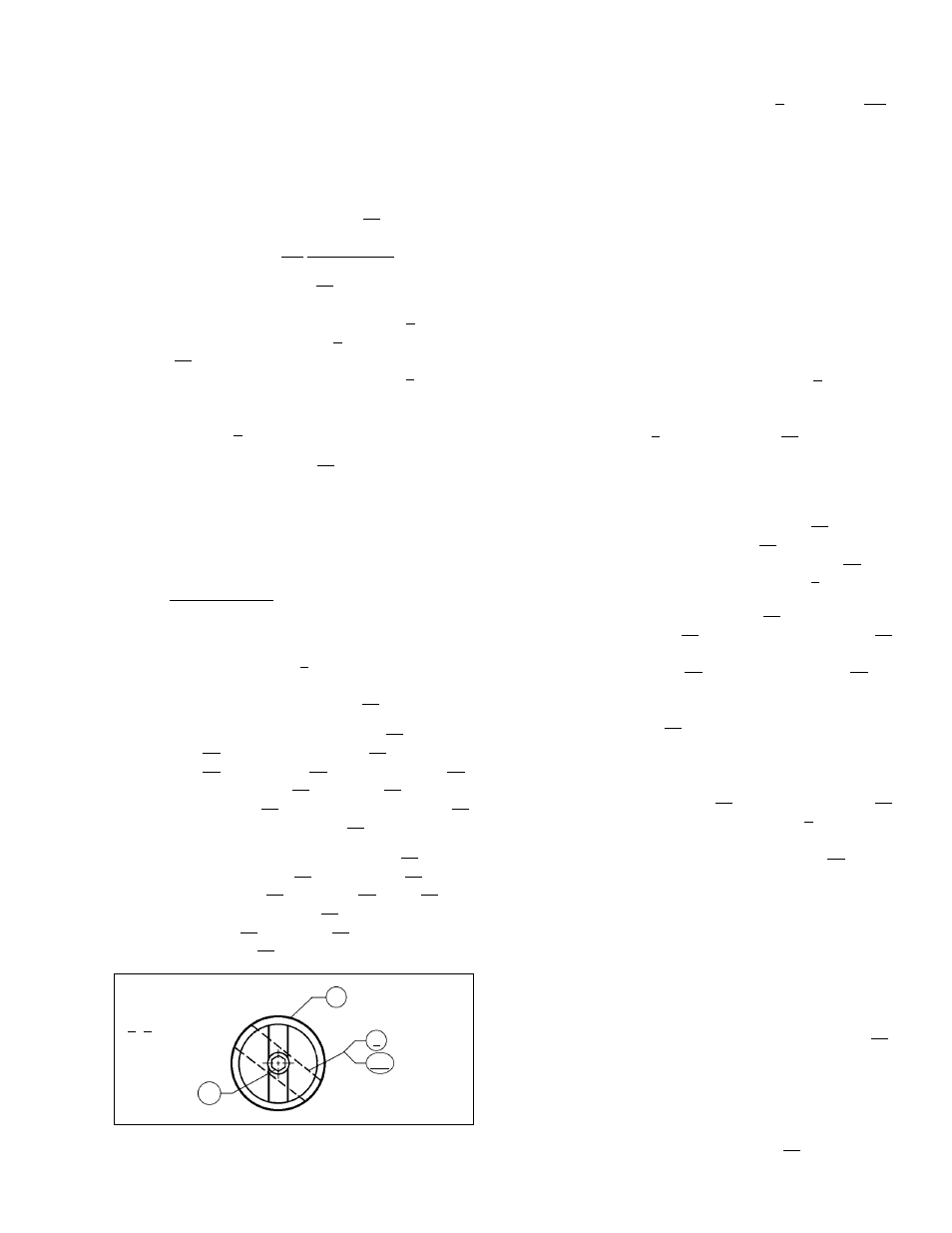

d.

Position the new positioner spacer (17)

over the valve stem (7 - Ranger, 3.2 -

Premier) end, oriented as shown below in

Figure 2.5.

e.

Put Locktite #242 thread locking sealant,

or equal, onto the set screw (77). Engage

the set screw (77) into the tapped end of

the spacer (17), until the set screw (77) is

projecting out of the spacer (17)

3/16" – 1/4" (5 – 6 mm).

f.

Position positioner baseplate (26) to

positioner mounting bracket (76) properly

oriented such that positioner baseplate

(26) bottom edge is parallel to the bottom

edge actuator arm housing (4). Opposite

side boltholes of bracket (76) must also

align with boltholes of actuator arm hous-

ing (4) and cover plate (13). Use four cap

screws (79) to secure the baseplate (26)

to the bracket (76). Place connected

parts (26, 76, 79) aside.

g.

Position bearing flanges (19) with re-

tainer ball bearing (18) over the spacer

(17). Align the bearing flange (19) bolt

holes with the arm housing (4) bolt holes.

h.

Position cover plate (13) over the bearing

flanges (19) aligning the cover plate (13)

bolt holes with those of the bearing

flanges (19). Hold cover plate (13) on

outer edge with fingers. NOTE:

Ensure

that the three tapped holes in the cover

plate (13) used to mount the bracket (76)

are near the 1 o'clock, 5 o'clock and 9

o'clock positions. Engage three cap

screws (31) to secure spacer (17), bear-

ing flanges (19) and cover plate (13)

securely to arm housing (4). NOTE

: It

may be necessary to rotate the actuator

manual handwheel operator (58) down-

wards, or alternately supply a small level

of air pressure (5-7 psig, .34 - .50 Barg) to

assist in aligning bolt holes for cap screws

(31). Do not tighten one cap screw (31)

until all three cap screws are partially

thread-engaged.

i.

Position connected parts (26, 76, 79) of

Step 4f., above, with the bracket (76) up

and pressing against the cover plate (13),

engaging the tongue-and-groove joint

between the positioner baseplate rotary

shaft (32) and the spacer (17) with its

protruding set screw (77). Engage new

cap screws (78) to secure the bracket

(76) to the cover plate (13).

17

7

3.2

77

Actuator Casings

(1, 2) on Topside

(Viewed looking

at Shaft end.)

Ranger

Premier

Figure 2.5: Spacer Orientation