Rs232 / fc88 – Fluid Components International ST51 User Manual

Page 8

FLUID COMPONENTS INTERNATIONAL LLC

ST51 MASS FLOW

This page is subject to proprietary rights statement on last page

8

Doc. No. 06EN003389 Rev. -

RS232 / FC88

Menu Control and Organization

Most entries require at least two key strokes; a Capital letter and the [ENTER] key, or one or more numbers and the [ENTER] key. All

user entries begin at the input mode prompt “>”,except when the instrument is in the Main Function Mode (just press the desired

function letter and [ENTER] to make an entry).

Backspaces are made using the backspace [BKSP] key. Some entries are case sensitive between numbers and letters. Be sure the

SHIFT key is pressed to indicate the correct case. A square after the prompt caret indicates the FC88 is in lower case. A slightly

raised rectangle in the same spot indicates the FC88 is in the upper case.

It is recommended that the FC88 be plugged into the instrument before power is applied. If the FC88 is plugged in while the

instrument power is on and the FC88 does not respond, press [ENTER], if there is still no response Press [N] or cycle the power.

Note:

The Zero and Span may be changed from the original calibration, provided the new values are within the original calibrated

range. i.e. If the original calibration was 1 to 100 SCFM (4-20mA), the new zero (4mA) must be equal to or greater than 1

SCFM, the new span (20mA) must be equal to or less than 100 SCFM.

Some entries require a Factory pass code. If this occurs contact FCI Field Service to continue programming the instrument. The

instrument will prompt the user when this is necessary. Do not change any parameters that require this code unless there is an absolute

understanding of the instrument's operation. The user can not exit some routines unless all entries are completed or the power is

recycled.

The top level of the menu is shown in Appendix B - Table 5. Enter the large letter in the tables below to activate a command. The user

may exit a command at any time entering “Q” [ENTER] in the menus: D, K, V, W, or Z.

Units

Select

E=English

M=Metric

Select

0= SFPS

5 = SMPS

or

1 = SCFM

6 = NCMH

or

2 = SCFH

7 = NCMM

or

3 = LBS/H

8 = KG/H

or

4 = GPM

9 = LPM

For Volumetric or Mass Flow

Select

R = Round pipe or duct

or

S = Square duct

Set

Diameter or Wide X High (in inches or mm)

Set

CMaxflow = Maximum flow rate (span)

Set

CMinflow = Minimum flow rate (zero)

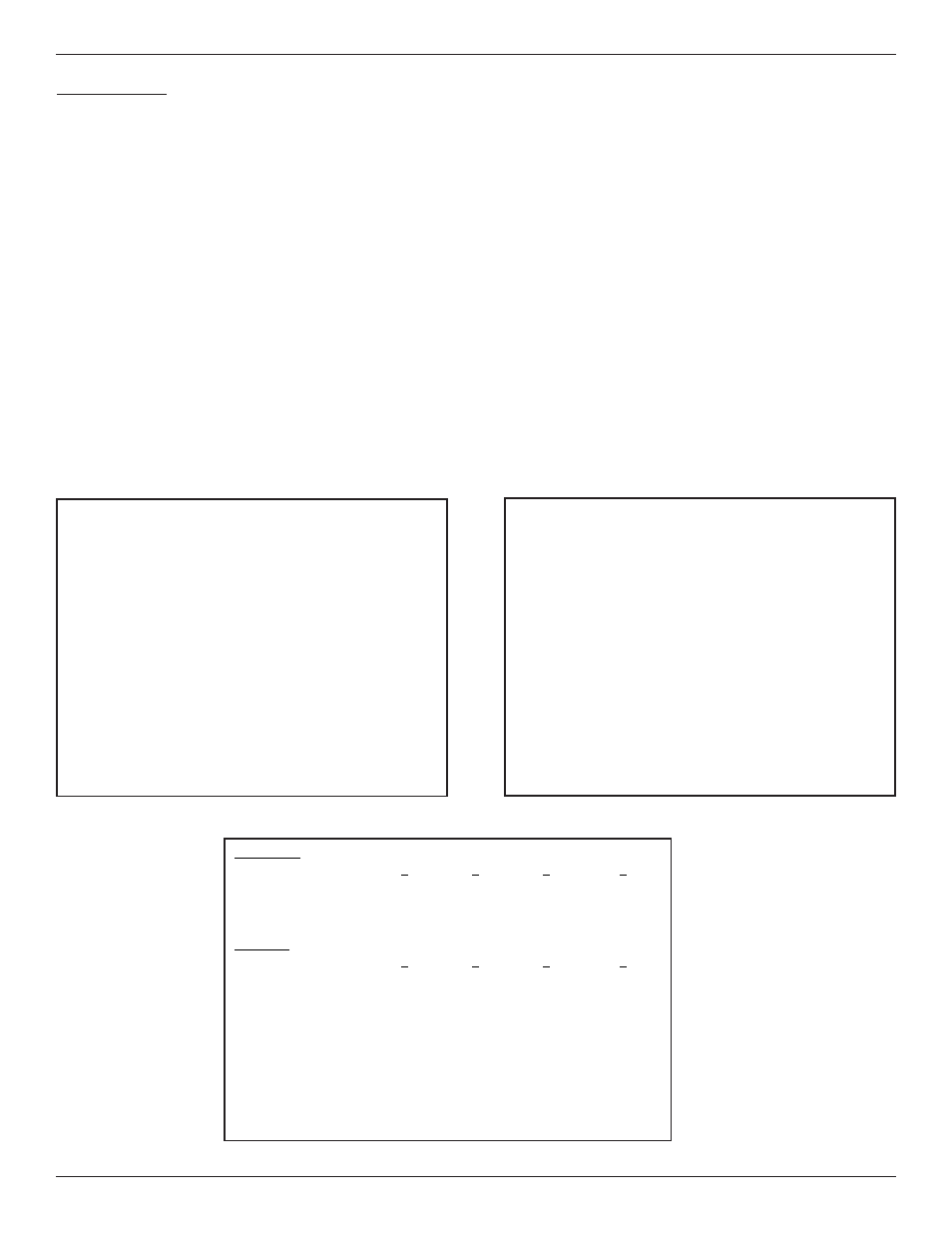

Table 2. “Z” Flow Units Set-Up and Scaling

Note: Changing units requires rescaling the unit (set new zero and span).

Analog out

Select

1

2

3

4

4-20mA out 1

Flow

Flow

Temp

Temp

4-20mA out 2

Temp

Flow

Flow

Temp

Pulse out

Select

1

2

3

4

Source out

Pulse

Pulse

Alarm0

Alarm0

Set

Factor

Factor

Set pt.0

Set pt.0

Set

Period

Period

State0

State0

Set

State0

State0

Sink

Pulse

Alarm1

Pulse

Alarm1

Set

Set pt.1

Factor

Set pt.1

Set

State1

State1

Period

State1

State1

Table 3. “V” Output Configuration Set-Up

Table 1. Diagnostics and Factory Settings

C Calibration Information

Display only: A/D, Delta-R, Ref-R data values

D Diagnostics

Display only: List of unit prameters.

K Factory Calibration Settings

Display only: Cal. parameters, i.e. linearization

and temperature compensation coefficients.

R Factory Reset

Replaces user data with factory calibration data