Acyclic operation description – Fluid Components International ST100 Series PROFIBUS PA User Manual

Page 8

ST100 Series Profibus PA

4

Fluid Components International LLC

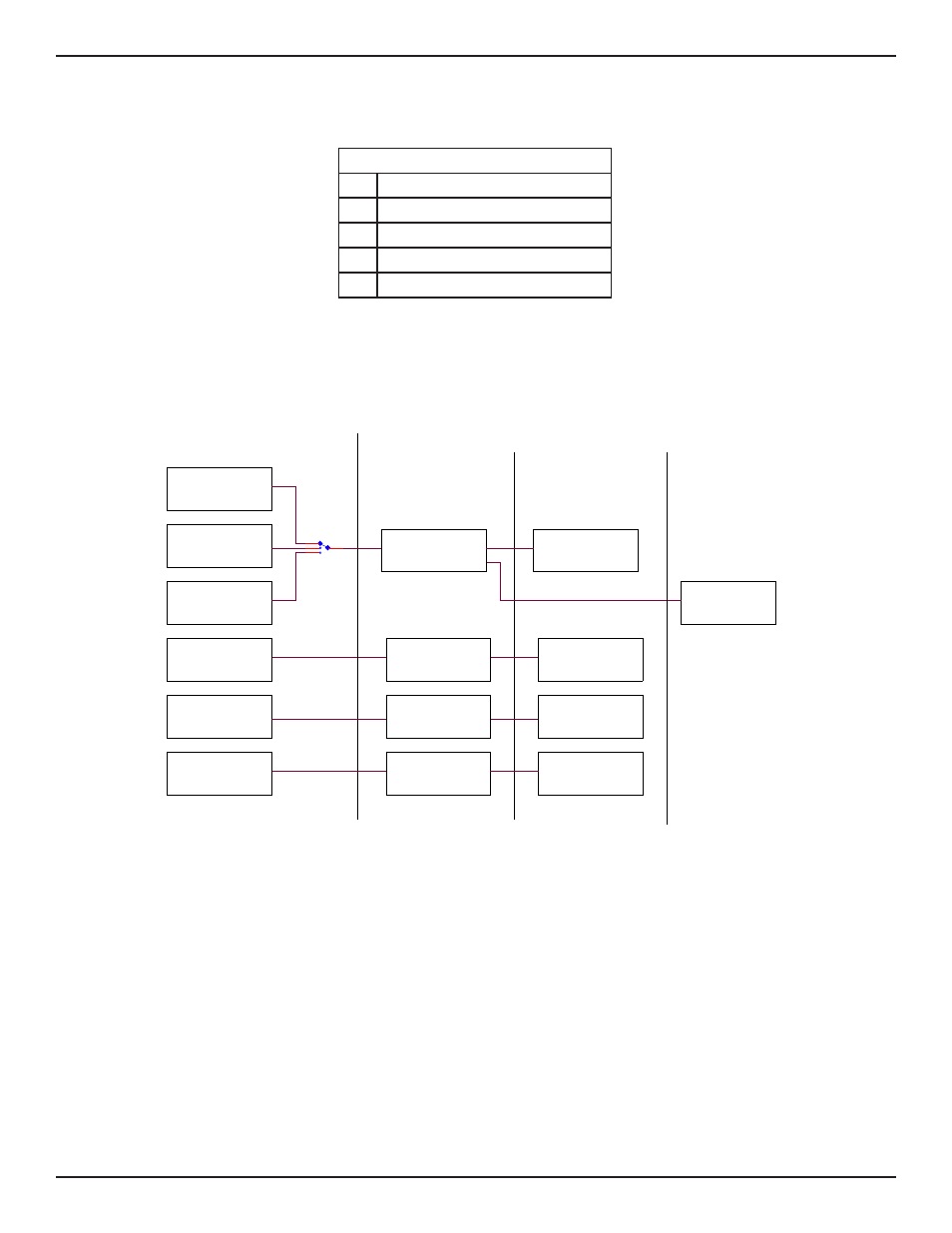

When configuring the ST100 it is very important to follow the Slot sequence described below. If a module is not needed make sure to load an

“EMPTY MODULE” in its place. In the example above the two “EMPTY_MODULE” modules are taking the place of the PRESSURE AI that is not offer

in this model, and the profile TOTALIZER. The recommended TOTALIZER to use is the ST100 “internal” Totalizer.

ST100 AI SLOT DEFINITION TABLE

1

FLOW

2

TEMPERATURE

3

PRESSURE

4

PROFILE TOTALIZER

5

FCI INT. TOTALIZER

Acyclic Operation Description

A number of transducer blocks that receive the process data from the instrument and a corresponding number of analog input blocks support the

acyclic data operation of the ST100. See diagram below for a quick overview of the process.

The ST100 implements the PROFIBUS PA Profile 3 for a multi-variable device. Profile 3 uses a function block model to organize the variables and the

parameters. The diagram shows the PROFIBUS PA function blocks. A class 2 master is needed to access the profile 3 function blocks.

PV - PROCESS FLOW

*

TV - FCI TOTALIZER

FCI TOTALIZER

SV - PROCESS

TEMPERATURE

AI BLOCK FOR FLOW

PROFIBUS PA - PROCESS VARIABLES

VOLUMETRIC FLOW

FLOW

2

3

1

4

+

AI BLOCK FOR

TEMPERATURE

AI BLOCK FOR

FCI TOTALIZER

*

OTHER FUNCTION BLOCKS

AI BLOCK FOR

FCI PRESSURE

PROCESS TEMPERATURE

PROCESS PRESSURE

PROFILE P3

TOTALIZER BLOCK

ST100 - PROCESS VARIABLES

VELOCITY FLOW

TRANSDUCER BLOCK VARIABLES

*

QV - PROCESS

PRESSURE

MASS FLOW FROM

ANALOG INPUT BLOCKS