Burkert Type 2051 User Manual

Page 21

21

Maintenance, Troubleshooting

installation procedure

10.3.2.

noTe!

Before installation, ensure that:

all components are clean and in perfect condition,

•

the spare parts and the grease are suitable for the operating

•

temperature of the actuator,

the lubricants are suitable for the different operating

•

temperatures.

installing the shaft (pos. 60):

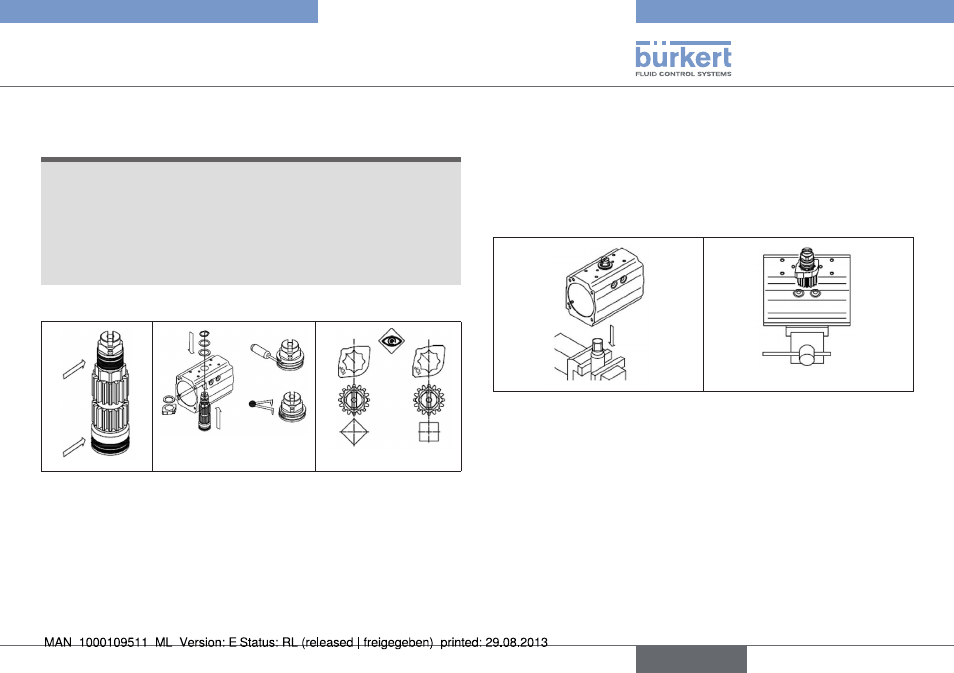

DIAGONAL PARALLEL

Installing the shaft

Fig. 12:

Install the shaft bearing bushes above (Pos. 06) and below (Pos.

→

07), grease the lower (Pos. 20) and upper (Pos. 21) sealing rings

and insert on the shaft,

Grease the surface of the shaft above and below,

→

Insert the shaft partly into the housing (Pos. 50), install the cam

→

(Pos. 01) in the required position, referring to the upper and lower

end of the shaft and the direction of rotation of the actuator during

operation. Insert the inner thrust washer (Pos. 08). Insert the shaft

all the way into the housing,

Fit the outer thrust washer (Pos. 08), the support washer (Pos. 10)

→

and the outer circlip (Pos. 18) using circlip pliers.

installing the pistons (pos. 40):

Fig. 13: Installing the pistons

Grease and fit O-rings (Pos. 16), piston guide jaws (Pos. 05) and

→

piston guide belt (Pos. 15),

Grease the inner surface of the housing (Pos. 50) and the gear

→

racks of the pistons (Pos. 40),

Place the shaft socket (Pos. 60) on an adequately attached

→

coupling,

Ensure that the cam is in the correct position (see

→

Fig. 13:),

If installation is in the standard direction of rotation, design ST

→

(closing clockwise), rotate the housing (Pos. 50) by 40-45°

clockwise (see

english

Type 2051