Burkert Type 8681 User Manual

Page 4

12

Structure

6.2.

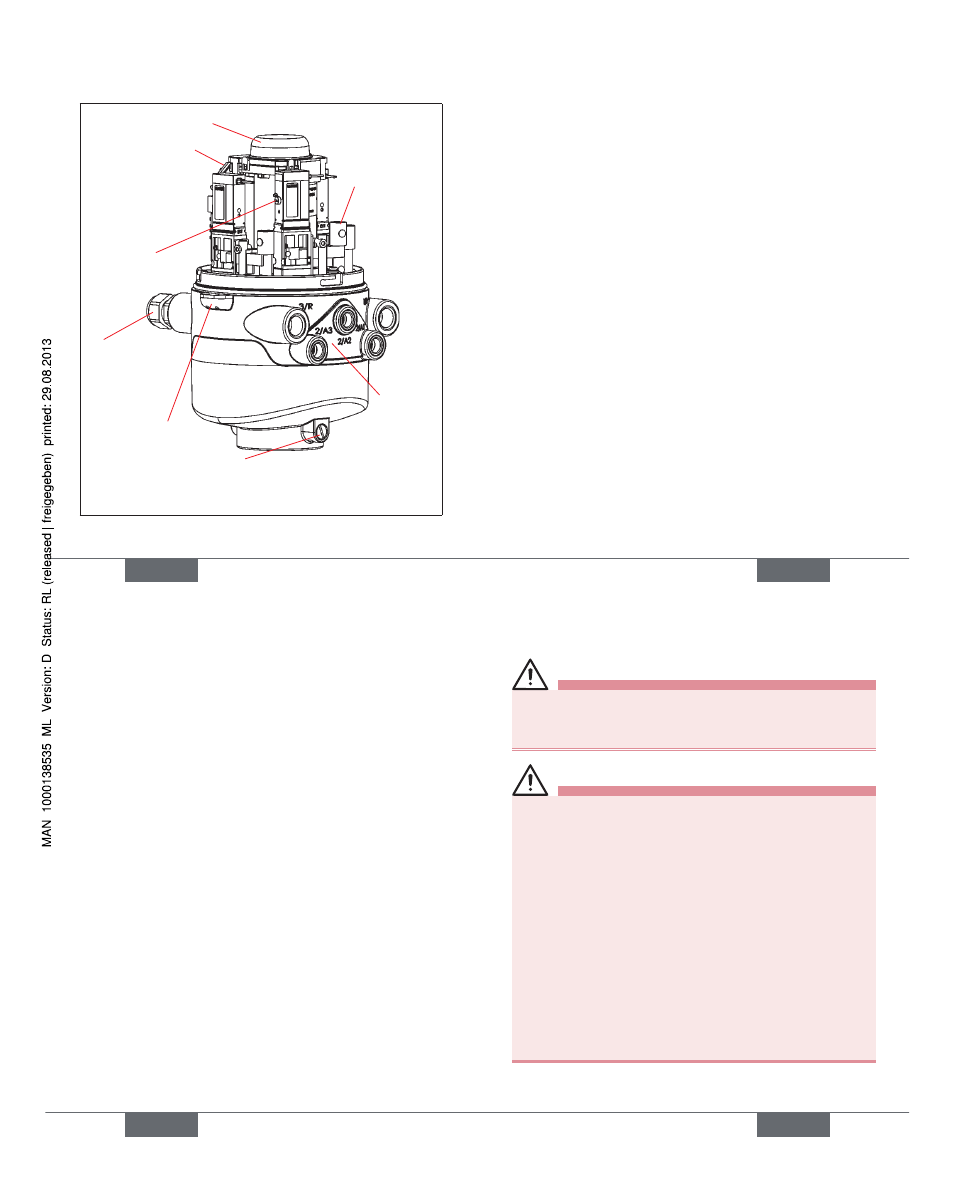

Pneumatic

connections

Locking/(shoulder) screws

as protection against pulling

off from the hub fl ange

Electrical

connections

(Cable

glands)

Sealing lug

Electronics module

(24VDC- or AS-i-

Design with service

interface, connection

terminals, DIP, Teach-

In-buttons)

Position measuring system with LED’s

Flow restriction

screw(s) of

solenoid valves

Mechanical

manual control

at solenoid

valves (red

levers)

english

13

TECHNICAL DATA

7.

Operating Conditions

7.1.

Ambient temperature: -10 ... +55 °C

Protection class: IP65 / IP67 according to EN 60529 or

IP69K according to IEC 40050-9

Mechanical Data

7.2.

Dimensions:

see data sheet

Housing material:

outside: PA, PP, PPO, VA

inside:

ABS, PA, PMMA

Sealing material:

outside: CR, EPDM

inside:

EPDM, FKM, NBR

Pneumatic Data

7.3.

Control medium:

Oil-free and dry air, neutral gases,

Quality classes in accordance with

DIN ISO 8573-1 (5 µm fi lter

recommended)

Dust content:

max. particle size 40 µm,

(quality class 5) max. particle density 10 mg/m

3

Water content:

max. pressure dew point -20 °C or

(quality class 3)

min. 10 °C below the lowest

operating

temperature

english

14

Oil content:

max. 25 mg/m

3

(quality class 5)

Temperature range

of compressed air:

-10 to +50 °C

Pressure range:

2.5 to 8 bar

Air rate of solenoid

valve:

110 I

N

/min (for de-/aeration, ventilation)

(110 I

N

/min - supplied state

200 I

N

/min - maximum typical fl ow-rate)

(Q

Nn

value according to defi nition for

pressure drop from 7 to 6 bar absolute

at +20 °C)

Connections:

Intake and exhaust air connection G1/4

Working connections

G1/8

Position Measuring System Data

7.4.

Stroke range:

0 ... 80 mm (measuring range)

Resolution:

0.1 mm

Total fault:

± 0.5 mm - when using a target as

mentioned in the manual

Electrical Data

7.5.

see chapter 9. 24 V DC - Design or 10. AS-I - Design or

11. DeviceNet- Design or 12. 120 V AC - Design .

english

15

ASSEMBLY / INSTALLATION

8.

DANGER!

Risk of injury from high pressure in the equipment!

Before loosening pneumatic lines and valves, turn off

•

the pressure and vent the lines.

WARNING!

Risk of injury due to electrical shock!

Before reaching into the system (except for the

•

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting!

Observe applicable accident prevention and safety

•

regulations for electrical equipment!

Risk of injury from improper installation!

Installation may be carried out by authorized techni-

•

cians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

Secure system from unintentional activation.

•

Following assembly, ensure a controlled restart.

•

english

Type 8681