Burkert Type 8681 User Manual

Page 11

40

120 V AC - DESIGN

12.

Connection

12.1.

left connection:

1 x M16 x 1,5 cable gland for

power supply and signals

right connection:

1 x M16 x 1,5 cable gland for

external initiator

Electrical Data

12.2.

Central power supply: 110 ... 130 V AC, 50/60 Hz

Power consumption

(stnd-by current):

10 mA at 120 V AC

Solenoid valves:

power

consumption

per solenoid valve:

max. 1,4 VA

(1,7 VA during activation)

power

consumption

per solenoid valve:

12 mA at 120 V AC

Operation mode:

Long-term operation (100 %)

english

41

Central display of the switching states:

13 mA with a power supply of

120 V AC per illuminated display

Outputs/binary

feedback signals:

S1out - S3out

Design:

NO contact, L switching,

short-circuit protection via auto-

matically resetting fuse

switchable output

current:

max. 50 mA per feedback signal

Output voltage

- active:

(operating voltage - 2 V)

- inactive:

max. 1 V in unloaded state

Feedback signal output: S4 out is directly connected to

S4

in

Input / proximity switches (external initiator: S4 in):

Power supply:

voltage present at control head

U

Nominal

= 120 V AC, 50/60 Hz

Current carrying capacity,

sensor power supply:

max. 0.7 A

Short-circuit

protection

Design:

DC 2- and 3-conductor,

NO contact, L-switching

input current 1-Signal:

I

Sensor

< 2 mA

english

42

Valve control inputs (Y1 - Y3):

Signal level - active:

U > 60 V AC

Signal level - inactive:

U < 20 V AC

Impedance:

> 40 kOhm

Electrical Installation

12.3.

WARNING!

Risk of injury due to electrical shock (120 V AC)!

When setting the position measuring system

•

(Teach-In), do not contact any live components!

Before reaching into the system (except for the

•

Teach-In procedure in a non-explosive atmosphere)

switch off the power supply and secure it to prevent

restarting

Observe applicable accident prevention and safety

•

regulations for electrical equipment!

Risk of injury from improper installation!

the

•

PE connection must be connected!

Installation may be carried out by authorized techni-

•

cians only and with the appropriate tools!

english

43

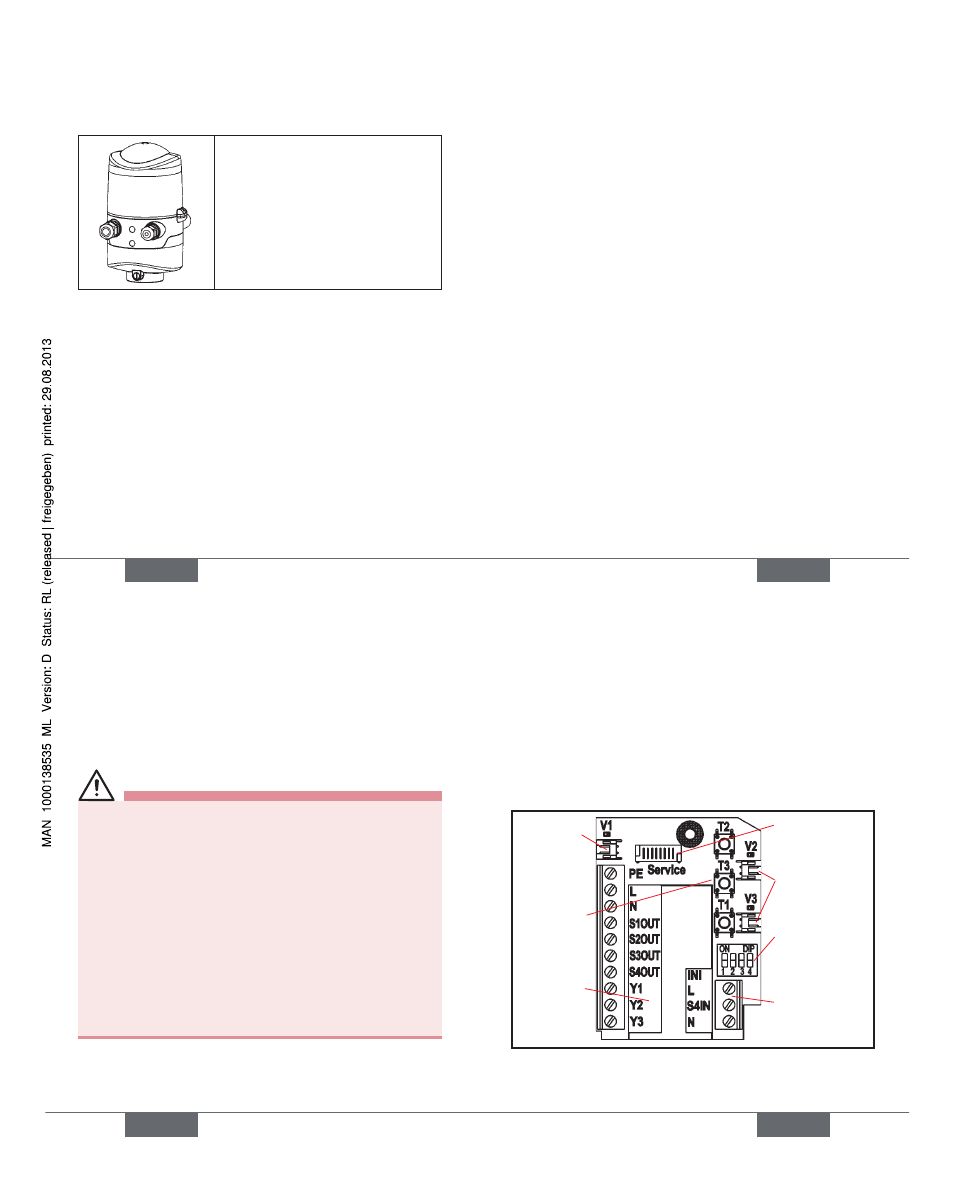

Cable gland:

Open the housing.

Assemble connection cables for signals and power

supply as well as for the external initiator.

Insert cables through the respective cable glands into

the interior of the housing.

Connect the wires to the connection terminals

according to the pin assignment described in the

fi gure. Fix them.

connection

for valve 1

with status

LED

terminal

strip 1

service

interface

DIP-switches

for color

coding the

LED‘s

terminal strip 2

(external

initiator)

Teach-In-

buttons

T1-3

connections for

valve 2, 3 with

status LED

english

Type 8681