Burkert Type 6144 User Manual

Page 4

english

12

8. ASSEMBLY

8.1. Safety instructions

WARNING!

Assembly work may result in hazardous situations.

• Such work may only be performed by persons with

appropriate technical knowledge and using suitable

tools!

• After an interruption of the electricity or the compressed

air supply, ensure that the process is started up again in

a defined or controlled manner!

Danger from unintentional activation of the system!

Unintentional start-up of the system may lead to injuries

and property damage.

• Use suitable means to prevent the system from being

activated unintentionally.

8.1.1. Devices which are designed for

use in zone 2/22

The user must ensure that this unit complies with the

degree of protection IP54 in accordance with EN 60529.

For example, by installing it in a suitable housing.

english

13

8.2. Fluid installations

WARNING!

Danger of injury from high pressure.

• Before detaching lines and valves, cut off pressure and

vent!

Risk of injury due to malfunction/escape of medium.

If the exhaust air from other processes is used to gen-

erate compressed air for the device, the seals may be

destroyed by the media contained in the air.

• Use only fresh air to generate compressed air for the

device.

Important operating conditions to avoid

malfunctions:

The valve must be at least 5 mm away from other

ferromagnetic materials.

Installation position: any, preferably with the drive

upwards.

Before assembly:

→

Clean pipes and flange connections.

→

To protect against malfunctions, install a filter (5 µm)

upstream of the valve.

english

14

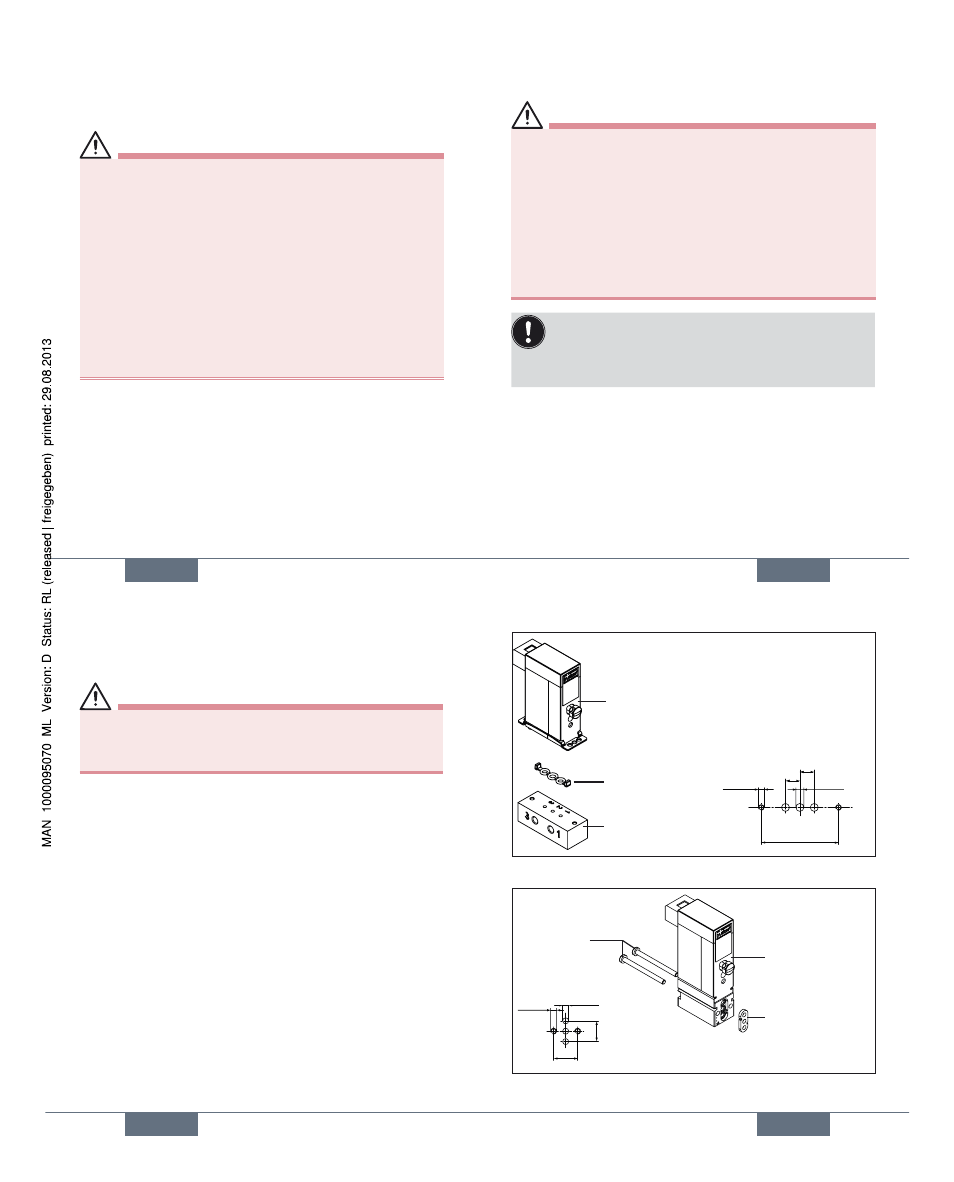

Assembly of Type 6144 with Bürkert flange:

(see Figure 1: Assembly drawing for Bürkert flange)

WARNING!

Danger of escaping fluids!

Connections will leak if the seal is not properly seated.

• Ensure that the supplied sealing mat is correctly seated.

→

Insert sealing mat into the valve.

→

Assign fluids 1, 2 and 3 correctly on the valve and con-

nection plate.

→

Drill holes in accordance with hole pattern.

→

Screw valve to connection plate

→

Check valve for proper seal

Assembly of Type 6144 with lateral flange:

(see Figure 2: Assembly drawing for lateral flange)

→

Assign fluids 1, 2 and 3 correctly on the valve and con-

nection plate.

→

Drill holes in accordance with hole pattern.

→

Screw valve to connection plate

→

Check valve for proper seal

english

15

Valve with fastening elements

Connection

plate

Sealing mat:

Hole pattern:

4

4

ø 2.0 (max.)

M1.6

21.5

1

2

3

Fig. 1:

Assembly drawing for Bürkert flange

Valve with

fastening

elements

Sealing mat:

Hole pattern:

6.4

5.5

ø 1.6 (max.)

M1.6

Fastening

screws

2

3

1

Fig. 2:

Assembly drawing for lateral flange (FS09)

Type 6144