Burkert Type 6606 User Manual

Page 7

24

note!

If the tightening torque is too great, the device may

be damaged!

Observe the maximum tightening torque of the screws!

•

Attach valve to manifold:

→

Screw in screws at 0.3 ± 0.05 Nm.

Tighten screws alternately, in two

steps:

1st step:

Tightening torque 0.1 ± 0.05 Nm

2nd step:

Tightening torque 0.2 ± 0.05 Nm

1

2

3

4

1st step

2nd step

0.1 ± 0.05 Nm 0.2 ± 0.05 Nm

Attach coil to body.

→

english

25

Danger!

Risk of electric shock if the protective conductor

function is defective!

After installing the coil, check the functionality of the

•

protective conductor (see chapter entitled “

8.3. Elec-

trical Installation”).

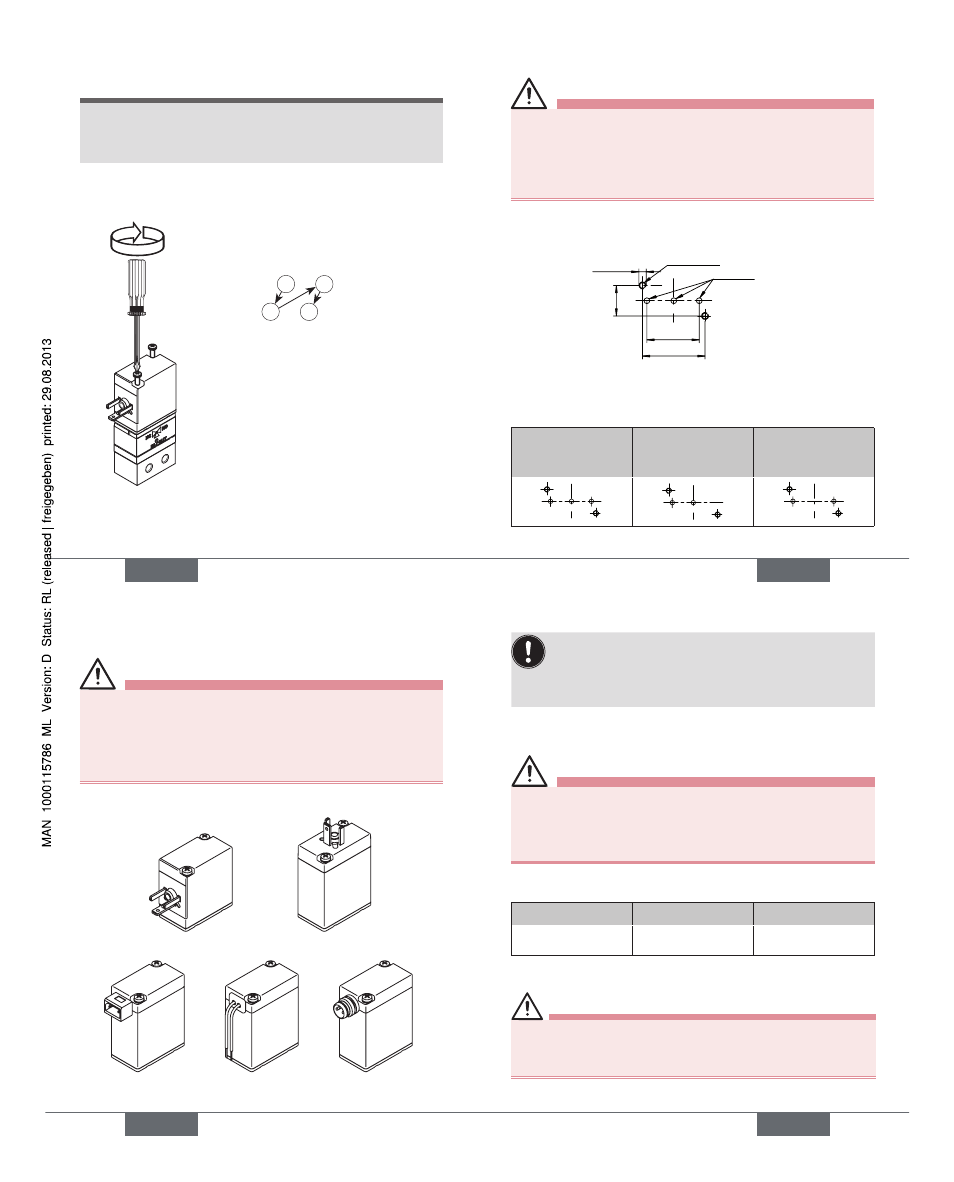

Dimensional drawing for manifold:

NO

IN/OUT

NC

M2.5

min. 7.5 deep

max. ø2.5

18

21.5

10.5

Arrangement of the bores:

3-way

2-way PVDF and

virtually dead

storage version

2-way PEEK /

PPS

english

25

26

8.3. electrical installation

Danger!

Risk of injury due to electrical shock!

Before reaching into the device or the equipment,

•

switch

off the power supply and secure to prevent reactivation!

Observe applicable accident prevention and safety

•

regulations for electrical equipment!

Types of electrical connections:

Rectangular connector Flying leads

Circular connector

Connection at side

Connection above

english

27

To ensure functional reliability, operate the valve with

the coil installed ex works only!

Note the voltage and current type as specified on

the type plate. Voltage tolerance ±10 %

Valves with flange body:

Danger!

Risk of electric shock if the protective conductor

function is defective!

After installing the coil, check the functionality of the

•

protective conductor.

Check functionality of the protective conductor.

→

Resistance

Test voltage

Test current

max. 0.1 Ω

12 V

1 A

Connection to cable plug:

Danger!

Risk of electric shock if protective conductor not

connected!

Always connect protective conductor!

•

Earthing connection (if fitted): Middle spade connection

english

27

Type 6126 / 6606