Burkert Type 6606 User Manual

Page 6

20

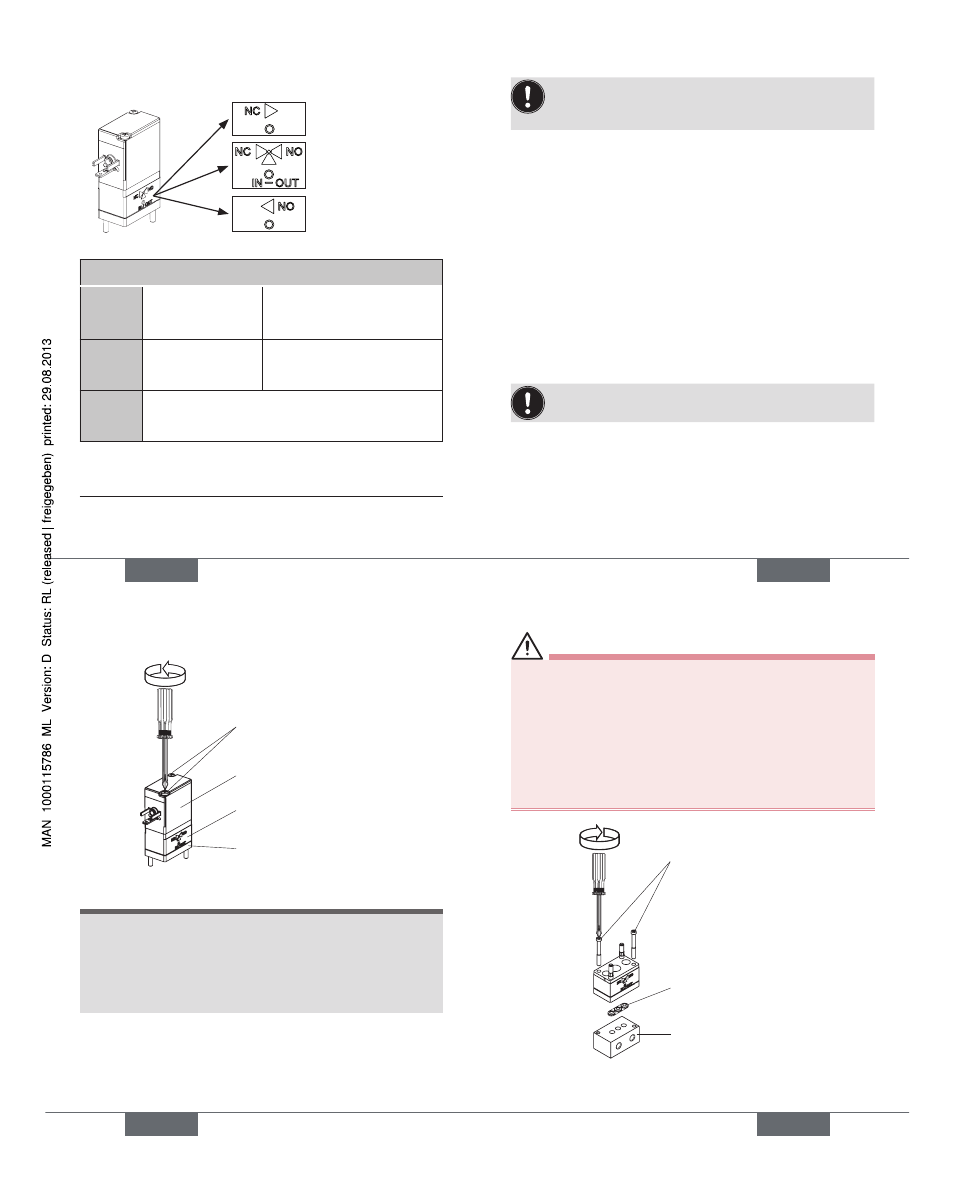

Circuit function (CF)*

A

T

B

Identification of the valve connections on the body:

NC

Normally Closed

Connection normally

closed, for CFA

NO

Normally Open

Connection normally open,

for CFB

IN/OUT for pressure connection (distributor) or

working connection (mixer), for CFT

* see also the description of the circuit functions in the chapter

entitled “

7.4. Pneumatic data”

english

21

The valve body must not be twisted by the fastening

screws or by screwing in the connecting nipples too

far!

The bodies with threaded or hose connection have fixing

eyelets for the screw connection from above with M3 and from

below with self-tapping screws BZ 3.9 x ... DIN 7971.

Body with threaded connection:

Use PTFE tape as sealing material

→

Screw in the connecting thread by hand only

→

Body with hose connection:

Use flexible silicone or FKM hose with 1.6 – 2 mm inner

→

diameter

To ensure functional reliability, operate the valve with

the coil installed ex works only!

english

21

22

Valve with flange connection:

Flange plate

Body

Coil

Screws for attaching

coil

note!

Malfunction / damage to device when detaching the

flange plate!

The valve features a pressed-in membrane which may be

damaged when the flange plate is detached.

Do not loosen the flange plate!

•

Loosen the screws which attach the coil and remove

→

the coil from the body.

english

23

Warning!

Danger - escaping medium!

Leaking connections if seals not fitted properly, if manifold

uneven or if surface quality of the manifold inadequate.

Make certain the seals included with delivery are

•

properly fitted in the valve.

Ensure that the manifold is even.

•

Ensure that the surface quality of the manifold is

•

adequate.

Seal

Screws for manifold

Tightening torque:

0.3 ± 0.05 Nm

Manifold

Insert the seal into the valve.

→

english

23

Type 6126 / 6606