Burkert Type 2712 User Manual

Page 3

5

→

Support control cone on the cylindrical part with the aid of a prism or

something similar.

→

Put on dowel pin and carefully knock in with a hammer.

→

Position the dowel pin in the center of the spindle axis.

For mounting actuator on valve body see Chapter “3.4”, page 9.

3.2.1 replacing valve seat

→

Remove actuator (see Chapter

“3.1”)

→

Select a suitable tool insert and

screw it into the installation tool.

→

Unscrew the old valve seat using the

installation tool and a wrench.

→

Clean the thread of the body and the

sealing surface with compressed air.

Installation

tool

Tool insert

Valve seat

→

Place the new valve seat on the installation tool.

The installation tool is available from your Bürkert sales office (see

Chapter “4”).

Warning!

Unsuitable lubricant may contaminate the medium.

In oxygen applications there is a risk of explosion.

▶ Only use approved lubricants for specific applications, such as oxygen or

analytical applications.

→

Grease the valve seat thread with stainless steel lubricant

(e.g. with Klüber paste UH1 96-402 from Klüber).

→

Manually screw the fitted valve seat into the body thread.

→

Screw valve seat tight using torque wrench. Observe tightening torque (see

“Tab. 2”).

DN

Torque [Nm]

DN

Torque [Nm]

4-15

20 ± 3

50

120 ± 8

20

28 ± 3

65

150 +10

25

40 ± 5

80

180 +10

32

65 ± 5

100

220 +10

40

85 ± 8

Tab. 2:

Tightening torques for valve seat installation (valve seat coated)

For mounting actuator on valve body see Chapter “3.4”, page 9.

english

6

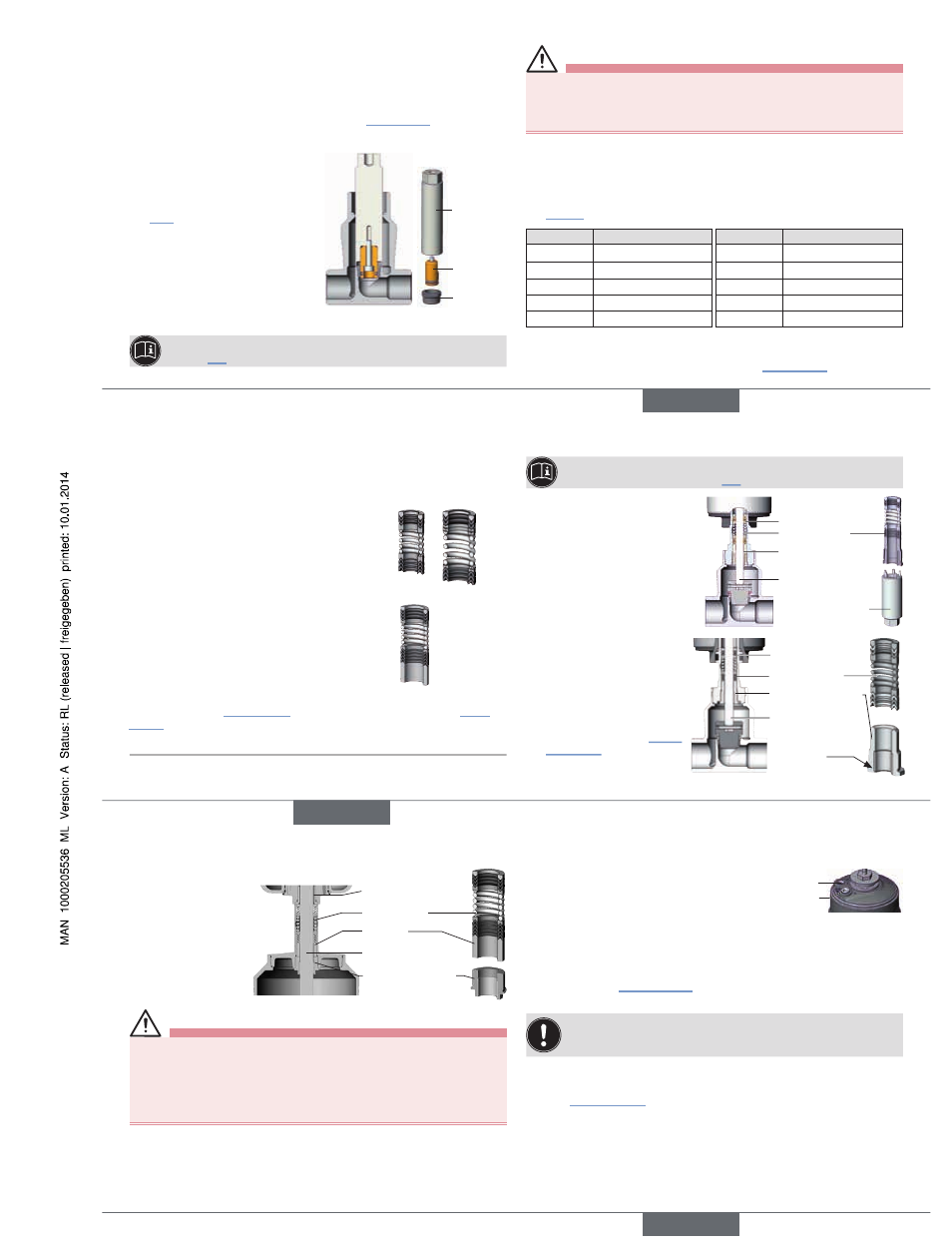

3.3 replacing packing gland seal set (only

Type 2301)

The seal set for the packing gland contains

SP10

SP14

SP10 / SP14

• 1 support ring

• 5 gaskets

• 2 or 3 pressure rings

1)

• 1 pressure spring

• 1 graphite seal

• Lubricant

SP22

• 1 support ring

• 7 gaskets

• 2 pressure rings

• 1 pressure spring

• 1 spacer

• 1 graphite seal

• Lubricant

Before the packing gland can be replaced, the actuator must be removed from

the valve body (see “3.1”, page 4) and the control cone removed (see “3.2”,

page 4).

1)

depending on the spindle diameter (10 or 14 mm)

Installation wrench or modified socket wrench is available from your

Bürkert sales office (see Chapter “4”).

PEEK spindle guide

Series-production status up to April

2012

→

Unscrew spindle guide with the

aid of the installation wrench

and an open-end wrench.

Installation

wrench

Packing gland

PEEK spindle

guide

Spindle

Packing gland tube

VA spindle guide

SP10/SP14

Series-production status from

April 2012

→

Unscrew spindle guide with

the aid of a modified socket

wrench and the open-end

wrench (see Chapter “Instal-

lation tools”).

Packing gland

VA spindle guide

Spindle

Packing gland tube

Hexagon

english

7

VA spindle guide SP22:

→

Unscrew spindle

guide with the aid of

an open-end wrench.

Packing gland

Spacer

Spindle

Packing gland tube

VA spindle guide

Warning!

Risk of injury from ejected parts!

When the spindle opening is exposed, the individual parts of the packing

gland are pressed out at an undefined speed when the control air connection

is pressurized.

▶ Before pressurizing with control air, safeguard the ambient area of the dis-

charge opening (e.g. place spindle on a firm base).

→

Press out packing gland:

For control function A and I:

Pressurize control air connection 1 with 6 ... 8 bar.

For control function B:

Pressurize control air connection 2 with 6 ... 8 bar.

1

2

Control air

connection

→

Grease the individual parts of the new packing gland with the supplied

lubricant.

→

Place the individual parts on the spindle in the specified direction and

sequence (see “Fig. 2”, page 8).

→

Push packing gland into the packing gland tube.

If the valve features a PEEK spindle guide (SP10 / SP14 series-pro-

duction status up to April 2012), we recommend replacing it with a

VA spindle guide. They are available from your Bürkert sales office.

→

Grease spindle guide thread with lubricant (Klüber paste UH1 96-402).

→

Screw spindle guide in again. Observe tightening torque

(see “Tab. 3”, page 8)!

english

Type 2301, 2712