Model sla7840 – Brooks Instrument SLA7840 User Manual

Page 30

4-6

Model SLA7840

Section 4 Maintenance

& Troubleshooting

Installation and Operation Manual

X-PR-SLA7800-RT-eng

Part Number: 541B048AAG

August, 2009

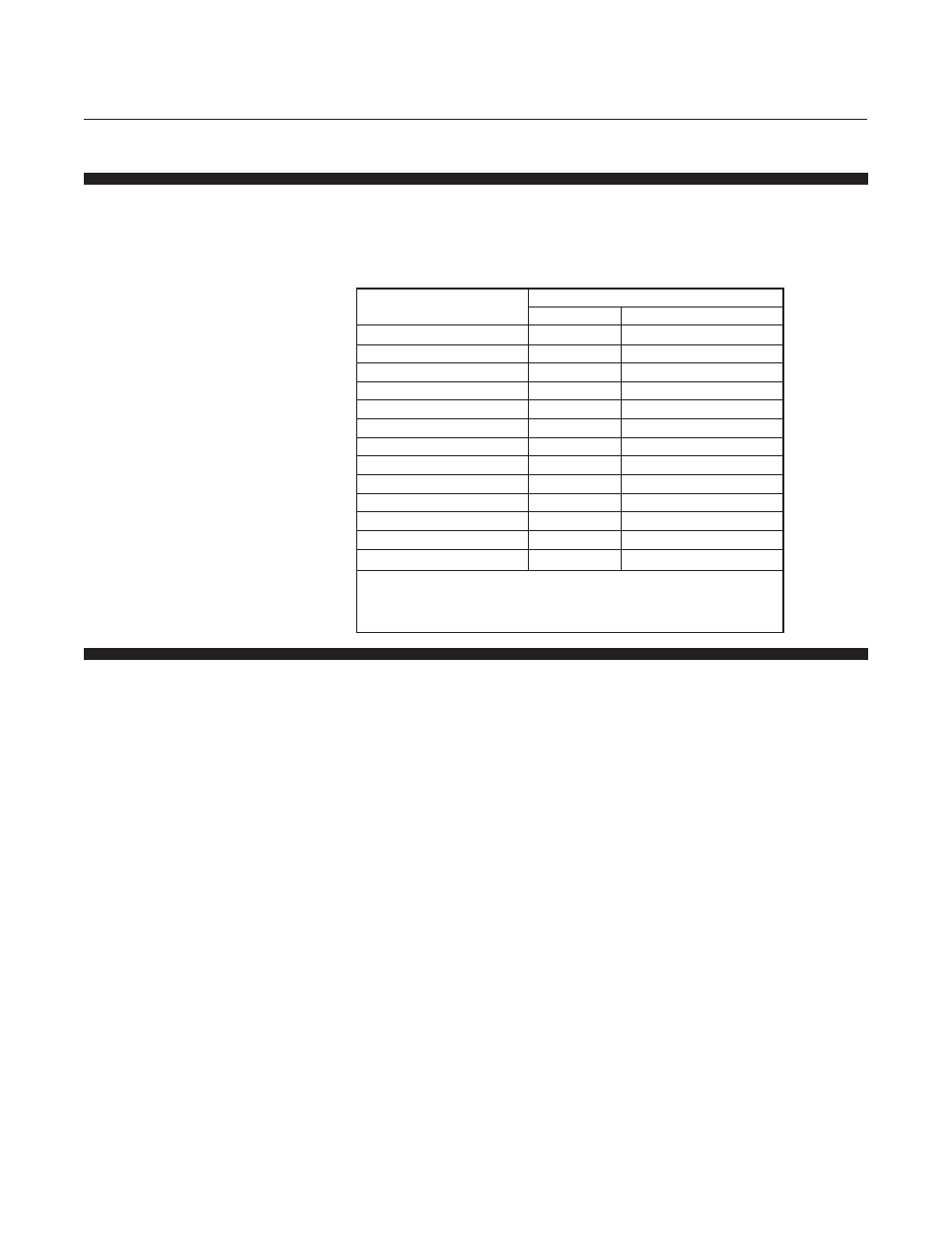

4-4 Orifice Sizing

The flow controller's orifice is factory-sized to a preselected gas, operating

pressure and flow range. Note that the orifice is marked with its size in

thousandths of an inch. When changing the gas operating pressure (inlet

or outlet), or flow range consult the factory for re-sizing information

4-5 Restrictor Sizing

The restrictor assembly is a ranging device for the sensor portion of the

controller. It creates a pressure drop which is linear with flow rate. This

diverts a sample quantity of the process gas flow through the sensor. Each

restrictor maintains a ratio of sensor flow to restrictor flow, however, the

total flow through each restrictor is different. Different restrictors (active

area) have different pressure drops and produce controllers with different

full scale flow rates. For a discussion of the interaction of the various parts

of the controller, you are urged to review Section 3-2, Theory of Operation.

If the restrictor assembly has been contaminated with foreign matter, the

pressure drop versus flow characteristics will be altered and it must be

cleaned or replaced. It may also be necessary to replace the restrictor

assembly when the mass flow controller is to be calibrated to a new flow

rate.

Restrictor assembly replacement should be performed only by trained

personnel. Consult Factory / Service center.

Restrictors

The Model SLA7840 remote transducer controller uses two types of

restrictor assemblies depending on full scale flowrate and expected service

conditions.

1. Wire mesh for Nitrogen equivalent flow rates above 3.4 slpm. These

restrictor assemblies are made from a cylinder of wire mesh and are

easily cleaned if they become contaminated in service.

2. Anti-Clog Laminar Flow Element (A.C.L.F.E.) - This type of restrictor

assembly is used for Nitrogen equivalent flow rates less than 3.4 slpm.

Table 4-2 Orifice Capacities

Orifice Size (inches)

Minimum Flow Rate (sccm)

0°C

(21.1°C)

0.0013

5.3

(5.7)

0.002

12.5

(13.5)

0.003

39.2

(42.2)

0.004

82.5

(88.9)

0.0055

190

(205)

0.007

374

(403)

0.010

748

(806)

0.014

1364

(1469)

0.020

2673

(2879)

0.032

6490

(6991)

0.048

12980

(13980)

0.062

22000

(2879)

0.078

31900

(34400)

Inlet Pressure = 10 psig

Outlet Pressure = 10 inches of water (0.4 psig) or less

Note: Flow Rate based on Nitrogen