Bm oval series, Horizontal line – Brooks Instrument BM50 User Manual

Page 23

2-5

Section 2 Installation

Installation and Operation Manual

X-PD-BM-Ovals-eng

Part Number: 541B031AAG

January, 2009

BM Oval Series

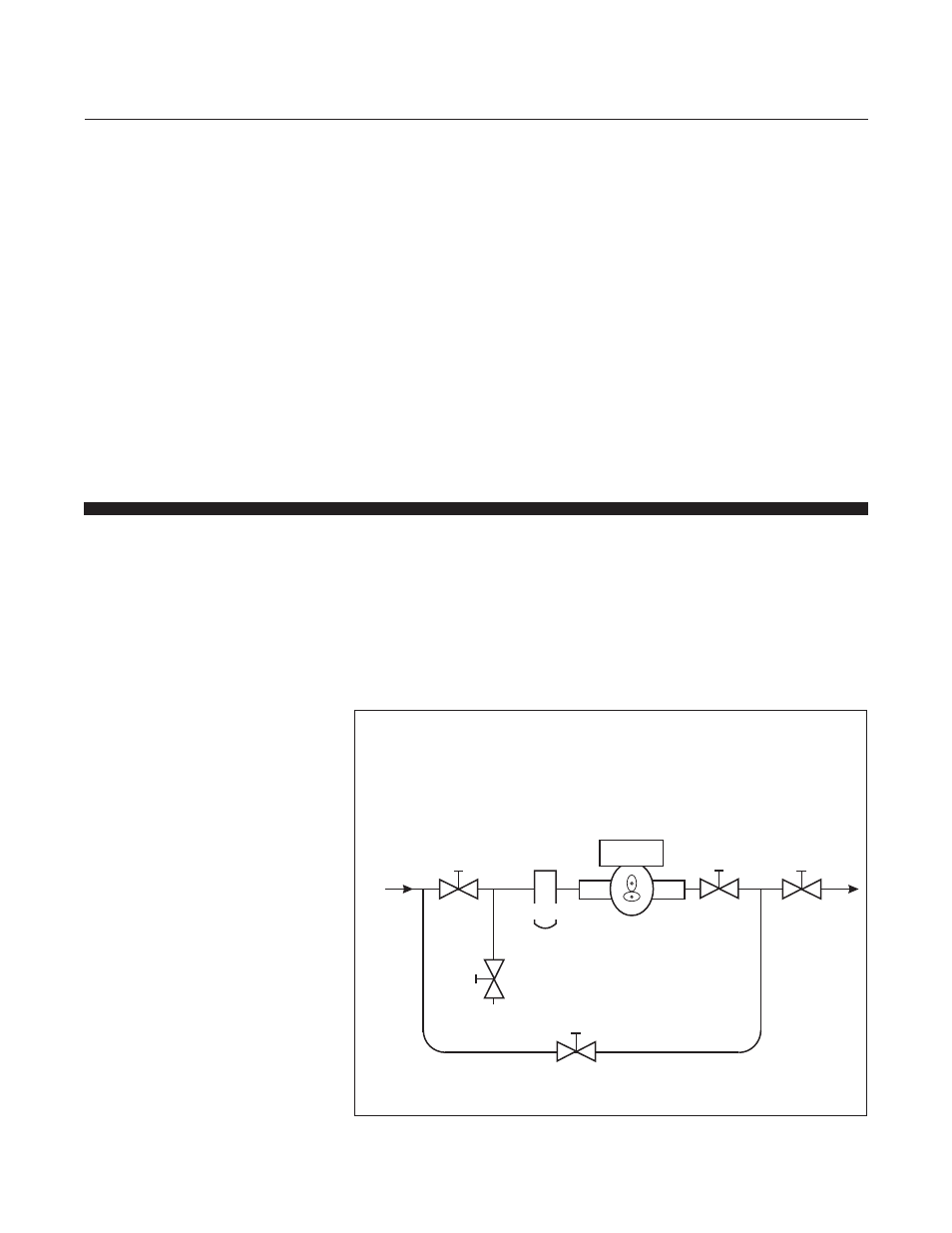

HORIZONTAL LINE

STRAINER

Drain

Valve

Bypass

Valve

Outlet

Valve

Control

Valve

Inlet

Valve

OVAL GEAR

FLOWMETER

Figures 2-5 Horizontal Installation.

(Refer to Table 2-1 for strainer size), ( See Figures 2-5 and 2-6).

4. Valves should be installed to facilitate removal of the flowmeter and

strainer, (See Figures 2-4 and 2-5).

5. Install the flowmeter on the discharge side of a pump whenever

possible.

6. Before installing the flowmeter, wash and clean the inside of the pipeline

with compressed air or steam. This is particularly important on new

pipelines.

7. Remove the protective covering from the flowmeter end connectors

before installation.

8. When making connection to the flowmeter make certain that no foreign

materials enter flowmeter body.

9. Ensure that the meter is installed so that the flow of the liquid is in the

direction of the arrows embossed on the meter body.

10. Refer to Figures 2-2, 2-3 or 2-4 for electrical connections.

2-7 Pre-Operation Procedures

1. After the flowmeter has been installed, slowly allow the liquid to flow in

bypass section of a horizontal installation or the main line of a vertical

installation. This will clear the line of any foreign particles.

2. Test the system for leaks.

3. Check the strainer for foreign material, after the first 50 gallons/200 liters

check periodically, particularly if the flow rate decreases.

NOTE: Foreign particles in the main line may cause damage to

the flowmeter.