English – CEMB USA ER100-i (B) User Manual

Page 82

82

Use and Maintenance Manual Rev. 12-2012

ENGLISH

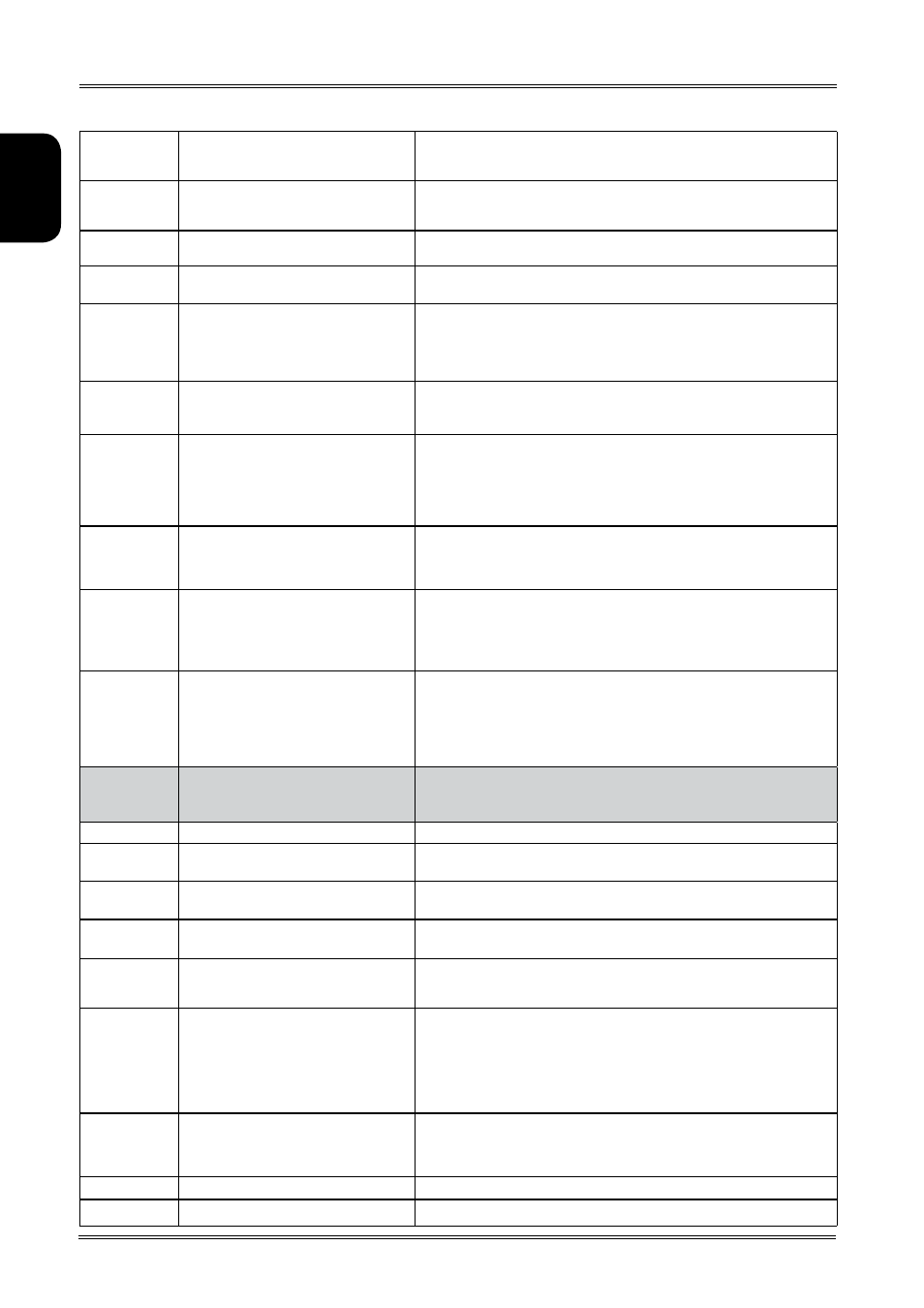

Err. 132/152

Internal/external laser stepper motor

movement stopped with STOP

command

1. Repeat the measurement avoiding to press the STOP button unless

for an emergency.

Err. 133/153

Different internal/external laser

positioning between the stepper motor

and the encoder

1. Check functioning of the stepper motor belt

2. Check the encoder on the stepper motor slide.

Err.201

Laser calibration file write error

1. Repeat the laser calibration function.

2. Replace the DOM.

Err.202

Laser calibration incorrect or inexistent

1. Repeat the laser calibration function.

2. Replace the DOM.

Err.203/

Err.204

Internal laser read error during

calibration.

1. Check that you have correctly fitted the laser calibration tool.

2. Check that the laser light spot is able to read the calibration tool.

3. Check that there are no objects that may interfere with calibration

tool reading.

4. Repeat the laser calibration function.

Err. 205/

Err. 208/

Err. 209

Error in the data read for laser

calibration.

1. Repeat the laser calibration function.

Err. 206/

Err.207

External laser read error (during

calibration).

1. Check that you have correctly fitted the calibration tool.

2. Check that the external laser light spot is able to read the spindle

and the calibration tool.

3. Check that there are no objects that may interfere with calibration

tool reading.

4. Repeat the laser calibration function.

Err. 210

Impossible to determine the type of error 1. Check the type of internal laser fitted on the slide.

2. Check the internal laser mounting bracket.

3. Check fitting of the internal laser slide.

4. Replace the complete internal laser unit.

Err. 211/

Err. 212/

Err. 213/

Err. 214

External laser read error

1. Check that the light spot is visible on the wheel to be measured.

2. Check that you have correctly mounted the wheel to be balanced.

3. Check that there are no objects other than the wheel in the laser

measuring range.

4. Repeat the dimension measurement.

Err. 221/

Err. 222/

Err. 223/

Err. 224/

Err. 225

Err. 226

Internal laser read error

1. Check that the light spot is visible on the wheel to be measured.

2. Check that you have correctly mounted the wheel to be balanced.

3. Check that there are no objects other than the wheel in the laser

measuring range.

4. Repeat the dimension measurement.

HARDWARE

ERRORS

CAUSE

CHECKS

Err.2

Hardware error from acquisition board.

---

Code 21

Error. Guard open during measurement. 1. Repeat the measurement keeping the guard closed until the end

of the spin.

Code 22

STOP during a measuring cycle.

1. Repeat the measuring cycle avoiding to press the STOP button

unless for an emergency.

Code 23

Error. Lift position during the measuring

cycle.

1. Enable the measuring cycle only when the lift is in rest position.

2. Do not move the lift during the measuring cycle.

Code 24

Pneumatic spindle released during the

measuring cycle.

1. Lock the wheel before starting the measuring cycle.

2. Check that the wheel is correctly locked on the spindle and that the

pneumatic system air pressure is sufficient to hold it locked.

Code 25

Rotation start timeout.

1. Check that there are no obstructions to normal wheel rotation.

2. Use the self-diagnostics function to check the encoder.

3. Use the self-diagnostics function to check proper functioning of the

electromagnetic switch.

4. Check the connection of the cables between the various boards.

AC versions - Check functioning of the power board relay

CC versions - Replace the motor drive board.

Code 26

Wheel braking timeout

1. Check functioning of the power board relay

2. Check the connection of the cables between the various boards.

AC versions - Check functioning of the power board relay

CC versions - Replace the motor drive board.

Code 27

Inverse rotation.

1. Use the self-diagnostics function to check the encoder.

Code 28

Unbalance measurement timeout.

1. Repeat the unbalance measuring cycle.

Diagnostics