Basic troubleshooting, Preliminary check-out, Tools and equipment for job – C.E. Niehoff & Co. N1609 Troubleshooting Guides User Manual

Page 3: Identification record, Caution

Page 3

TG50E

Section B: Basic Troubleshooting

Basic Troubleshooting

1.

Inspect charging system components for damage

Check connections at B– cables, B+ cables,

B+ interconnect cable, B– interconnect cable, and

alternator-to-regulator harness. Repair or replace

any damaged component before troubleshooting.

2.

Inspect all vehicle battery connections

Connections must be clean and tight.

3.

Determine battery voltage and state of charge

If batteries are discharged, recharge or replace

batteries as necessary. Electrical system cannot

be properly tested unless batteries are charged

95% or higher. In addition, open circuit voltages

must be within ± 0.2 V.

4.

Connect meters to alternator

Connect red lead of DMM to alternator anti-drive

end B+ terminal and black lead to alternator

anti-drive end B– terminal. Clamp inductive

ammeter on anti-drive end B+ cable.

5.

Operate vehicle

Observe charge voltage at batteries with engine

running (nom. 27-28 V).

If charge voltage is above

32 V, immediately shut

down system. Electrical

system damage may occur if

charging system is allowed

to operate at excessive

voltage. Go to Table 1.

If voltage is at or below regulator setpoint, let

charging system operate for several minutes to

normalize operating temperature.

6.

Observe charge volts and amps

Charge voltage should increase and charge amps

should decrease. If charge voltage does not in-

crease within ten minutes, continue to next step.

7.

Batteries are considered fully charged if charge

voltage is at regulator setpoint and charge amps

remain at lowest value for 10 minutes.

8.

If charging system is not performing properly,

go to Chart 1, page 4.

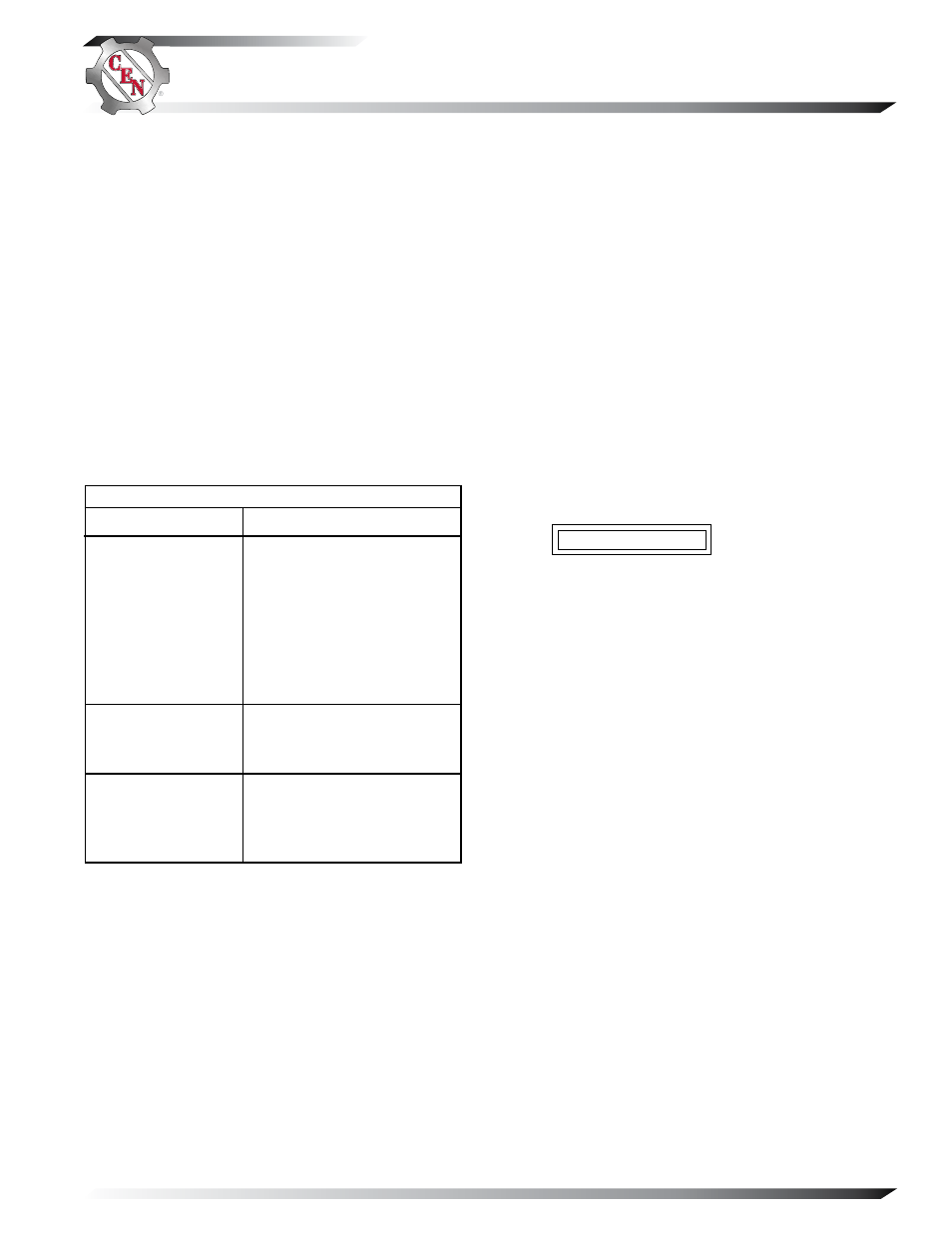

SYMPTOM

ACTION

TABLE 1 – System Conditions

Check: loose drive belt; low bat-

tery state of charge.

Check: current load on system

is greater than alternator

can produce.

Check: defective wiring or poor

ground path; low regula-

tor setpoint.

Check: defective alternator or

regulator.

Check: wrong regulator.

Check: high regulator setpoint.

Check: defective regulator.

Check: alternator.

Check: broken drive belt.

Check: battery voltage at alterna-

tor output terminal.

Check: defective alternator

or regulator.

Low Voltage Output

High Voltage Output

No Output

Preliminary Check-out

Check symptoms in Table 3 and correct if necessary.

Tools and Equipment for Job

• Digital Multimeter (DMM)

• Ammeter (digital, inductive)

• Jumper wires

Identification Record

List the following for proper troubleshooting:

Alternator model number ________________________

Regulator model number _______________________

Setpoint listed on regulator _____________________

CAUTION