C.E. Niehoff & Co. N1335 Troubleshooting Guides User Manual

Page 2

Page 2

TG0052A

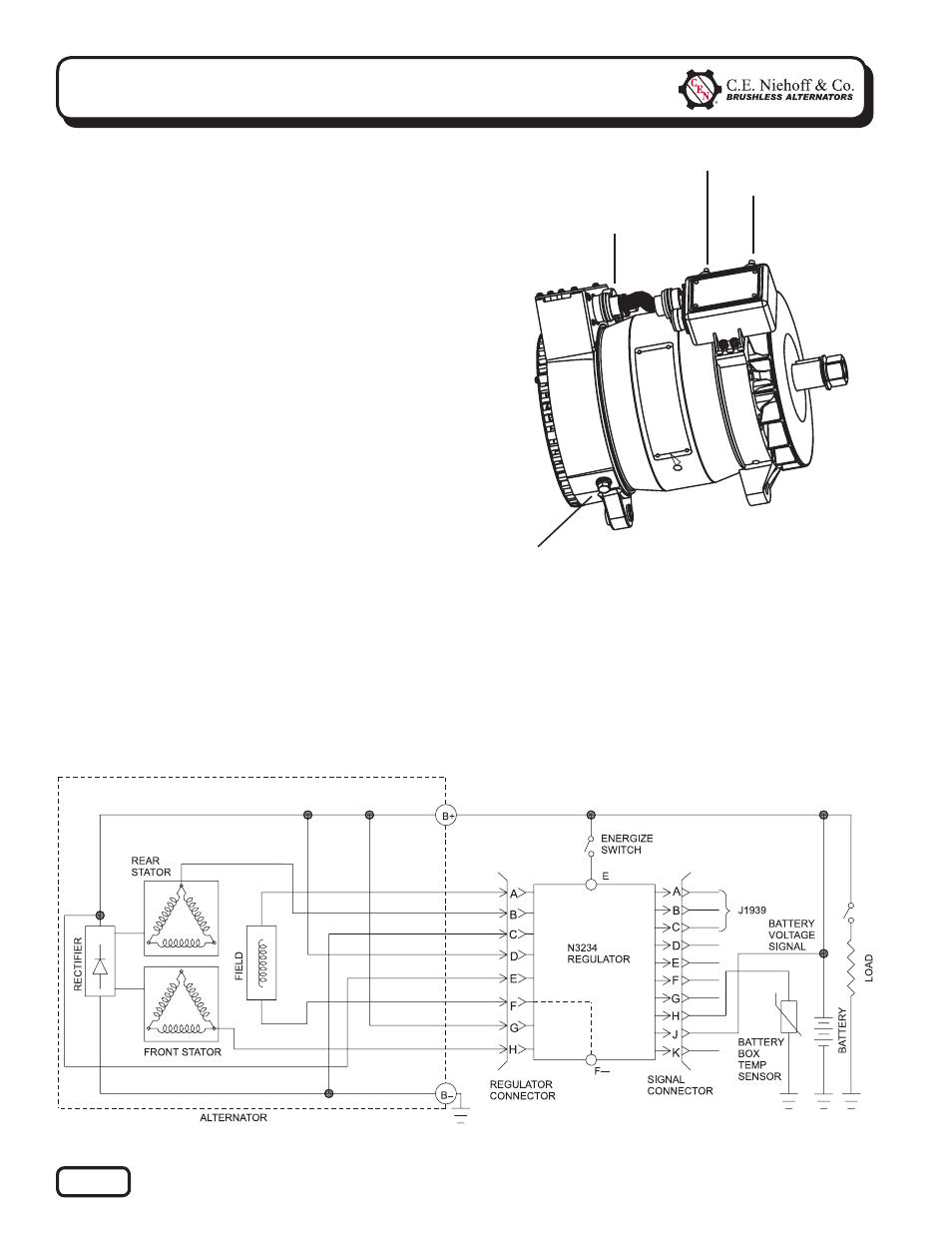

Section 1: Wiring Diagram

CEN N1335 Alternators

Description and Operation

N1335 28 V 300 A alternators are internally rectified.

All windings and current-conducting components are

non-moving, so there are no brushes or slip rings to

wear out.

After engine is running,

N3234 regulator receives ener-

gize signal. Regulator monitors alternator rotation and

provides field current only when it detects alternator

shaft rotating at or above idle speed.

After regulator detects alternator rotation, it gradually

applies field current, preventing an abrupt mechanical

load on accessory drive system. The soft start may take

up to 5 seconds.

N3234 regulator used with these units also

• is negative temperature compensated. Setpoint is

28.8 ± 0.5 V at 72 F when configured to operate with

6TMF type batteries.

• provides overvoltage cutout (OVCO). Regulator will

trip OVCO when system voltage rises above setpoint

by 3 V for longer than 3 seconds. OVCO feature

detects high voltage and reacts by opening alternator

field circuit and turning off alternator. Restarting

engine or waiting until system voltage drops 5 V

below setpoint will reset OVCO circuit.

• maintains alternator steady-state output voltage at

regulated settings as vehicle electrical loads are

switched on and off.

Figure 2 — N1335 Alternators with N3234 Regulator

Figure 1 — N1335 Alternator and

N3234 Regulator Terminals

B+ terminal

(next to regulator connector)

T

E terminal

B–

terminal

T

T

T

F- terminal