Electric vehicles, And plug-in hybrid electric vehicles, Applications – Atec Yokogawa-WT1800 User Manual

Page 9: Hev), Phev)

Applications

Applications

Applications

Keyword

Keyword

Keyword

In

In

I

I

In

In

n

n

In

In

n

In

In

ve

v

ve

ve

v

v

rt

t

rt

rt

er

er

r

er

s

s

s

s

s

s

s

s

s

ec

ec

ec

ec

ti

ti

ti

ti

ti

i

i

on

on

on

on

on

on

on

on

n

on

o

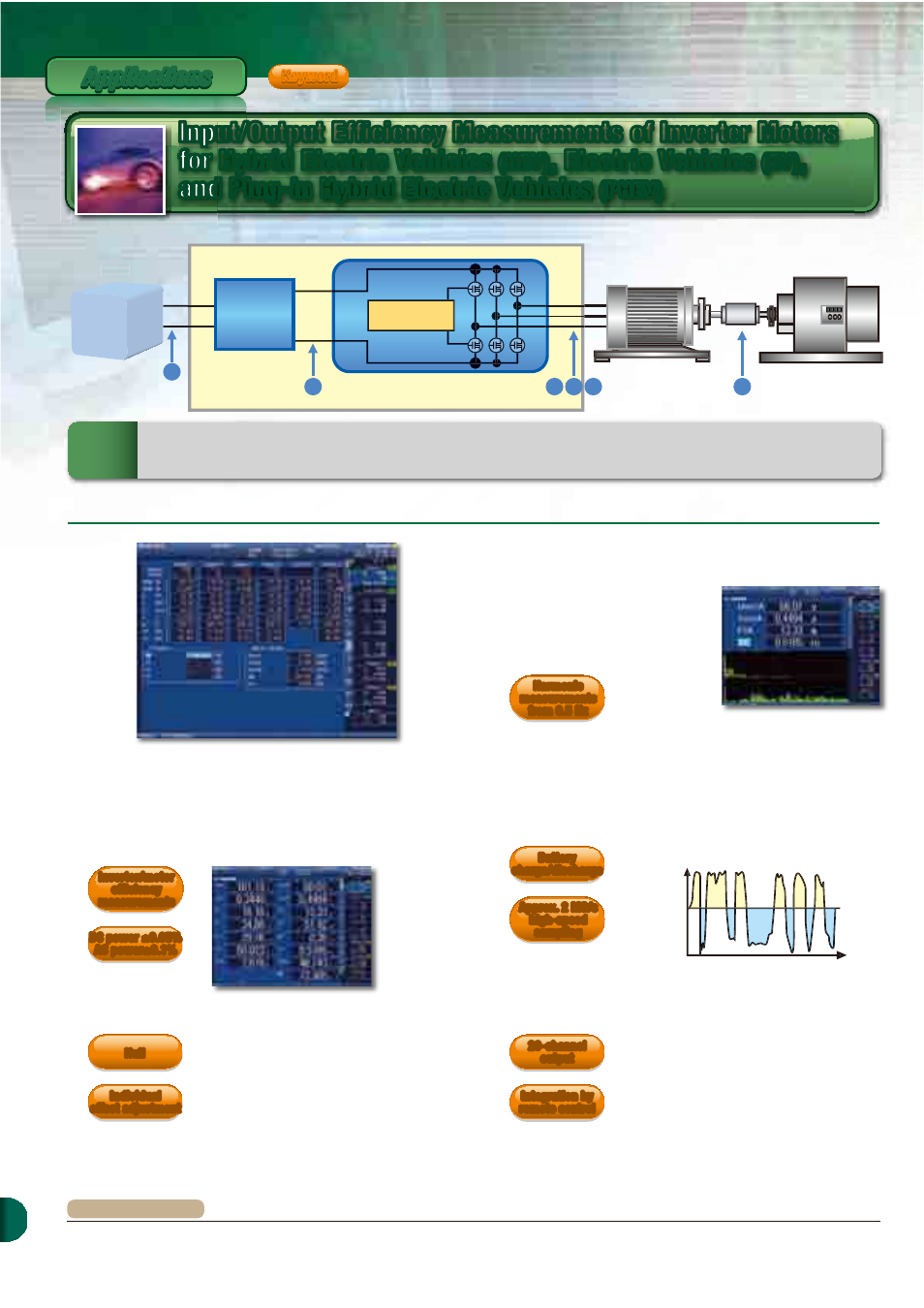

In motor testing, evaluation is performed at

various rotation speeds from low to high speeds.

The WT1800 supports the lower limit frequency

of 0.5 Hz to make it possible to measure

harmonics at a very low motor rotation speed

without using an external sampling clock.

n Inverter, motor, and DC/DC converter efficiency

measurements

n Battery charge and discharge measurements

In integrated measurement, the battery charge and discharge can be evaluated.

Instantaneous positive and negative values captured at an approximately 2 MS/s high-speed

sampling rate are integrated, respectively, and each of the total values is displayed.

A single WT1800 unit is capable of measuring the effective power, frequency, and motor

output in order to measure the total efficiency, including inverter and motor efficiency and

battery DC/DC conversion efficiency.

DC power accuracy has been improved to ±0.05% to ensure more accurate measurements.

n Offset correction measurement by null function

After you finish connecting the wires for inverter motor testing,

you may find a value will not become zero due to the influence of

the ambient environment or other reasons and the offset value

will be applied inappropriately even before starting

measurements.

With the previous power analyzer model*, there is no choice

other than to turn all inputs on and off collectively, so unintended

offset adjustment is performed even for inputs for which you do

not want adjust.

With the WT1800, only an input for which you want to perform

offset adjustment can be turned on and off.

n DA output and remote control (/DA option)

Sometimes you may want to check changes in data, along with

other measurement data (temperature, etc) at the same time

when you acquire communication data, such as voltage, current,

power, and efficiency data. A DA output function allows you to

retrieve analog signals on up to 20 channels.

Also, remote control signals make it possible to control the start,

stop, and reset of integration by external analog signals.

Furthermore, integration can be linked by inputting an analog

trigger signal from another device.

*Comparison with Yokogawa’s previous model WT1600

In

In

In

In

pu

pu

pu

pu

p

p

t

t

t

t

Modulate and convert DC to AC signals

Drive circuit

Booster

Converter

section

Mo

M

to

r

To

rque

/

rota

ti

on

sensor

Lo

ad

1

2

3 4 5

M

s

Batteries

Typical repetitive high-speed charging and

discharging signals

Effective power

amount (Wh+)

Effective power

amount (Wh-)

Charge

Discharge

Charge current amount Ah (power amount Wh) and discharge

current amount Ah (power amount Wh) can be integrated, respectively.

Input/Output Efficiency Measurements of Inverter Motors

for Hybrid Electric Vehicles

(HEV)

, Electric Vehicles

(EV)

,

and Plug-in Hybrid Electric Vehicles

(PHEV)

Input/Output Efficiency Measurements of Inverter Motors

for Hybrid Electric Vehicles

(HEV)

, Electric Vehicles

(EV)

,

and Plug-in Hybrid Electric Vehicles

(PHEV)

pu

Inp

p

p

p

p

p

p

p

n

n

n

n

n

n

n

n

I

I

I

I

npu

Inpu

for

fo

fo

fo

r

r

or

and

and

and

and

Overview

The WT1800’s ability to perform up to 6 power input measurements makes it possible to evaluate the battery’s charge and discharge characteristics, and test and evaluate the

efficiency between the input and output of inverters. A motor evaluation function (/MTR option) makes it possible to simultaneously monitor changes in the voltage, current, and

power, as well as changes in the rotation speed and torque.

Advantages of WT1800

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

WT1805-50-H-HE/B5/G6/DT/DA/MTR: 5 power inputs, current input range 100 μA to 5.5 A (measuring AC/DC current sensor output), built-in printer, dual harmonic, delta computation, DA output, motor

evaluation function

Typical Product Configuration

DC power ±0.05%

AC power±0.1%

DC power ±0.05%

AC power±0.1%

Individual

offset adjustment

Individual

offset adjustment

Battery

charge/discharge

Battery

charge/discharge

20-channel

output

20-channel

output

Integration by

remote control

Integration by

remote control

Null

Null

Inverter/motor

efficiency

measurements

Inverter/motor

efficiency

measurements

Harmonic

measurements

from 0.5 Hz

Harmonic

measurements

from 0.5 Hz

Approx. 2 MS/s

high-speed

sampling

Approx. 2 MS/s

high-speed

sampling

*Also refer to the features of other applications.

*Als

o refer

to t

he features of other app

lication

s

n Harmonic measurements from a 0.5 Hz low frequency

(/G5 and /G6 options)

10