Sidewall termination installation – John Wood Commercial - 300-400K BTU User Manual

Page 25

25

sidewall termination installation

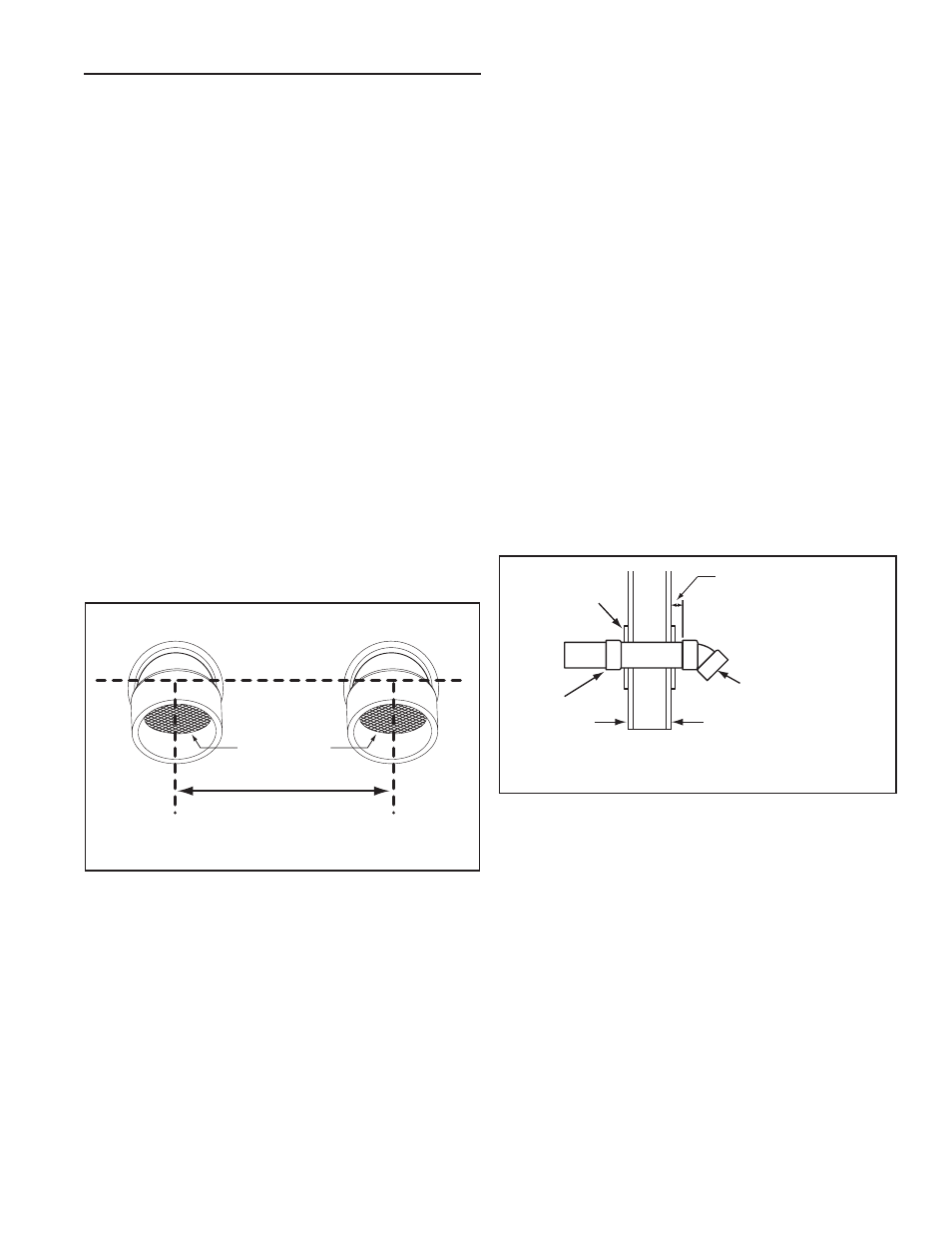

1. Determine the location for the termination(s).

2. If installing only vent (exhaust) piping in a Power Vent

configuration through a sidewall; ensure that all exterior

sidewall clearance requirements for the termination, shown

in Figure 48 on page 33, are being maintained. These

clearances and those cited by local and national codes must

be maintained.

3. If installing both intake air and vent piping in a Direct Vent

configuration through a sidewall; ensure that all exterior

sidewall clearance requirements for the terminations, shown

in Figure 49 on page 34, for the vent and intake air termination

are being maintained. These clearances and those cited by

local and national codes must be maintained.

4. If installing both an intake air and vent termination in a

Direct Vent configuration through a sidewall there must

be a minimum of 24 inches (61 cm) separation, measured

on vertical center line, between the intake air and vent

terminations, see Figure 22.

note:

In colder climates this separation should be increased

to at least 48 inches (122 cm) between the intake air and

vent termination or any other appliance vent that discharges

moisture-laden air such as clothes dryers. This will reduce

possibility of frost over from side winds blowing exhaust

vapors to the intake air termination and is recommended for

Canadian installations.

5. If installing both intake air and vent terminations in a Direct

Vent configuration through a sidewall the intake air and

vent terminations must be installed at the same elevation

measured on horizontal center line - see Figure 22.

VENT (EXHAUST)

TERMINATION

INTAKE AIR

TERMINATION

INSTALL ON

ELEVATION

CENTERLINE

24 INCHES (61 cm) MINIMUM

48 INCHES (122 cm) IN COLDER CLIMATES

KEEP INTAKE AND VENT

TERMINATION SCREENS

CLEAR OF DEBRIS

SIDEWALL TERMINATION - DIRECT VENT

STANDARD TERMINATIONS

figure 22

6. When the intake air and/or vent piping from multiple water

heaters will terminate at the same location through a sidewall,

the vent terminations can be grouped together in close

proximity - 0 inches/touching. The intake air terminations

can also be grouped together in close proximity - 0 inches/

touching.

However, the distance between the closest vent and intake

air terminations must be a minimum of 24 inches (61 cm).

In colder climates this separation should be increased to at

least 48 inches (122 cm). See Figure 22.

7. Cut a 5 inch (13 cm) diameter hole for 4 inch pipe or 7 inch

(18 cm) diameter hole for 6 inch pipe where the pipe(s) will

pass through the wall.

note:

beware of concealed wiring and piping when cutting

through the wall.

8. Cut a length(s) of pipe being installed 3.5 inches (8.9 cm)

to 9.5 inches (24.1 cm) longer than the wall thickness at the

Vent Termination – exhaust gases of this water

heater are less than 140°F. In cold climates water vapor in

the exhaust gases will condense into a cloud of vapor where

the vent exits the building. This vapor can gradually discolor

exterior building surfaces. The vent termination should be

located where this vapor cloud and potential discoloration

are not a concern. Extending the exposed vent piping up to

a maximum of 6 inches (15.2 cm) from the wall helps vapor

from being trapped along a building’s face. To avoid this

problem, the vent can also be terminated vertically through

the roof, see Vertical Termination Installation on page 23.

9. Cement the intake air and/or vent termination to the section(s)

of pipe cut to length in the above Step.

10. Slide the included metal wall plate(s) over the pipe(s) to stop

against the intake air and/or vent termination. Place some

silicone caulking (field supplied) on the back of the wall

plate(s) to secure it to the wall.

11. Working from outside, slide the pipe and termination(s)

assembled in the above steps through the wall. Ensure the

termination(s) is pointed down towards the ground. See

INTERIOR WALL

EXTERIOR WALL

FROM

WATER

HEATER

COUPLING

SIDEWALL TERMINATION INSTALLATION

INTAKE AIR AND/OR VENT (EXHAUST)

METAL PLATES

INSTALL INSIDE

AND/OR OUTSIDE

FACTORY SUPPLIED

STANDARD TERMINATION

POINTED DOWN

TOWARDS THE GROUND

INCREASE EXPOSED VENT

PIPING UP TO A MAXIMUM

OF 6 INCHES (15.2 cm) FROM

WALL TO HELP PREVENT VAPOR

FROM DISCOLORING THE WALL

SURFACE IN COLDER CLIMATES

figure 23

12. Place a bead of silicone caulking (field supplied) around the

gap between the installed pipe(s) and the wall. Apply enough

to fill the gap between the pipe(s) and wall.

13. Press the wall plate flush against the outside wall.

14. Working from the inside apply enough silicone caulking on

the back of the interior wall plate(s) to hold it in place and

slide the wall plate over the installed pipe(s).

15. Install a coupling to the end of the pipe(s) inside the building.

before the silicone caulking has time to completely set go

outside the building and ensure the termination(s) is still

pointing down towards the ground. See Figure 23.

16. return to Power Vent Installation on page 22 or Direct Vent

Installation on page 22 to complete the installation of the intake

air and/or vent piping between the termination(s) and the

water heater.