Xylem FM500 ULTRASONIC FLOW METERS User Manual

Page 7

Page 7

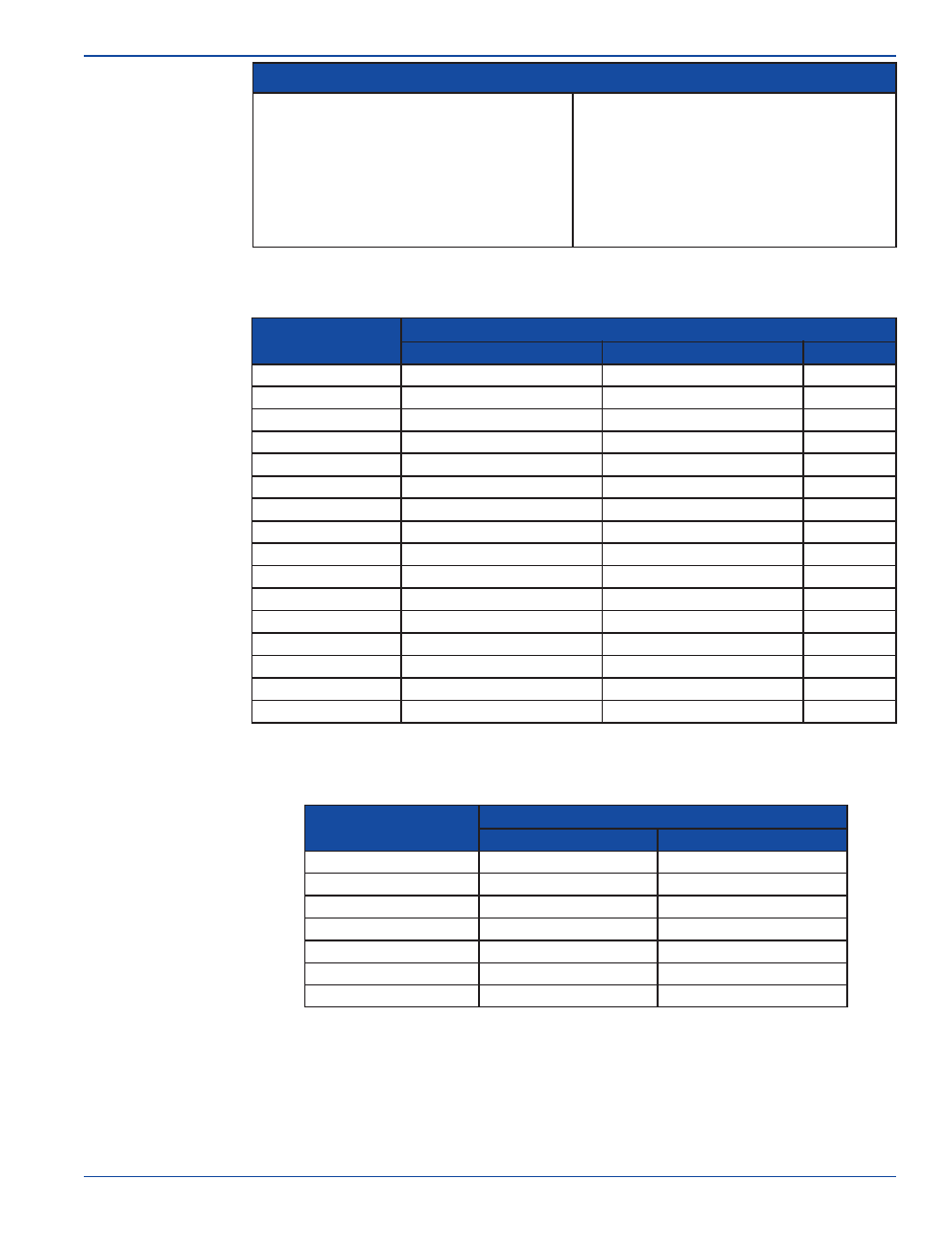

1.4

Fluid

Requirements

1.6

Straight Pipe

Length

Requirements

1.5

Pipe

Requirements

Doppler Operation

Transit Time Operation

!

!

0.02% to

15% (200 to 150,000 ppm)

Must conduct sound

Must contain sound reflecting particles such

as air bubbles, sand, etc.

Doppler measurement requires

particles be

present in the flow stream to “reflect” the

sound waves.

!

!

0% to

10% (0 to 100,000 ppm) of particles

Must conduct sound

Must be relatively clean fluid

Transit Time measurement requires relatively

“clean” fluid. Fluids containing from

are

acceptable.

Note: Do not attempt to measure very low flow velocities in the Doppler mode, the particles can fall out of

suspension resulting in error or failure.

Pipe Material

Pipe Size Ranges and Maximum Wall Thickness

Doppler Mode Pipe Size Range

Brass (Naval)

2“ to 100” (63mm to 2500mm)

Max Pipe Wall

Copper

FRP (fiberglass Reinforced Plastic)

.500” (13mm)

Iron (cast)

Iron (ductile)

Nylon

Polyethylene (HDPE)

Polypropylene

PVC / CPVC

304 Stainless Steel

Polyethylene (LDPE)

304L Stainless Steel

316 Stainless Steel

Steel (1% carbon hard)

Steel (carbon)

Titanium

Transit Time Mode Pipe Size Range

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

1“ to 100” (25mm to 2500mm)

1“ to 100” (25mm to 2500mm)

1“ to 100” (25mm to 2500mm)

1“ to 100” (25mm to 2500mm)

1“ to 100” (25mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

1-1/2“ to 100” (40mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

2“ to 100” (63mm to 2500mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

.500” (13mm)

2.00” (50mm)

2.00” (50mm)

2.00” (50mm)

1.00” (25mm)

.500” (13mm)

1-1/2“ to 100” (40mm to 2500mm)

1-1/2“ to 100” (40mm to 2500mm)

1-1/2“ to 100” (40mm to 2500mm)

1-1/2“ to 100” (40mm to 2500mm)

Note: The outside surface of the pipe must be clean and smooth. Insulation, coatings, rust and other surface

imperfections should be removed before installing the transducers. The inside surface of the pipe must be smooth to

properly reflect the sound wave.

Type of Disturbance

Straight Lengths of Pipe Required

Upstream from Transducers

Flange

5 x Nominal Pipe Size

Reducer

o

90 Elbow

Gate valve

Pump

Downstream from Transducers

o

Two 90 Elbows - 1 Direction

o

Two 90 Elbows - 2 Directions

5 x Nominal Pipe Size

7 x Nominal Pipe Size

5 x Nominal Pipe Size

10 x Nominal Pipe Size

5 x Nominal Pipe Size

15 x Nominal Pipe Size

5 x Nominal Pipe Size

20 x Nominal Pipe Size

5 x Nominal Pipe Size

25 x Nominal Pipe Size

5 x Nominal Pipe Size

25 x Nominal Pipe Size

5 x Nominal Pipe Size

Note: The sound wave beam is only affected by fluid that actually passes through the beam and therefore, the meter

will not measure with high accuracy if the fluid velocity is not consistent across the entire pipe diameter. Flow

disturbances such as pumps, elbows, tees, and valves in the flow stream can cause swirl patterns and vortices that

will affect the measurement. Install the transducers on a straight run of pipe as far as possible from any

disturbances. The distance required for high accuracy will depend on the type of disturbance.

Ultrasonic Flowmeter