YSI 6500 Environmental Process Monitor User Manual

Page 48

Proper Use and Care of the 6500

Section 5

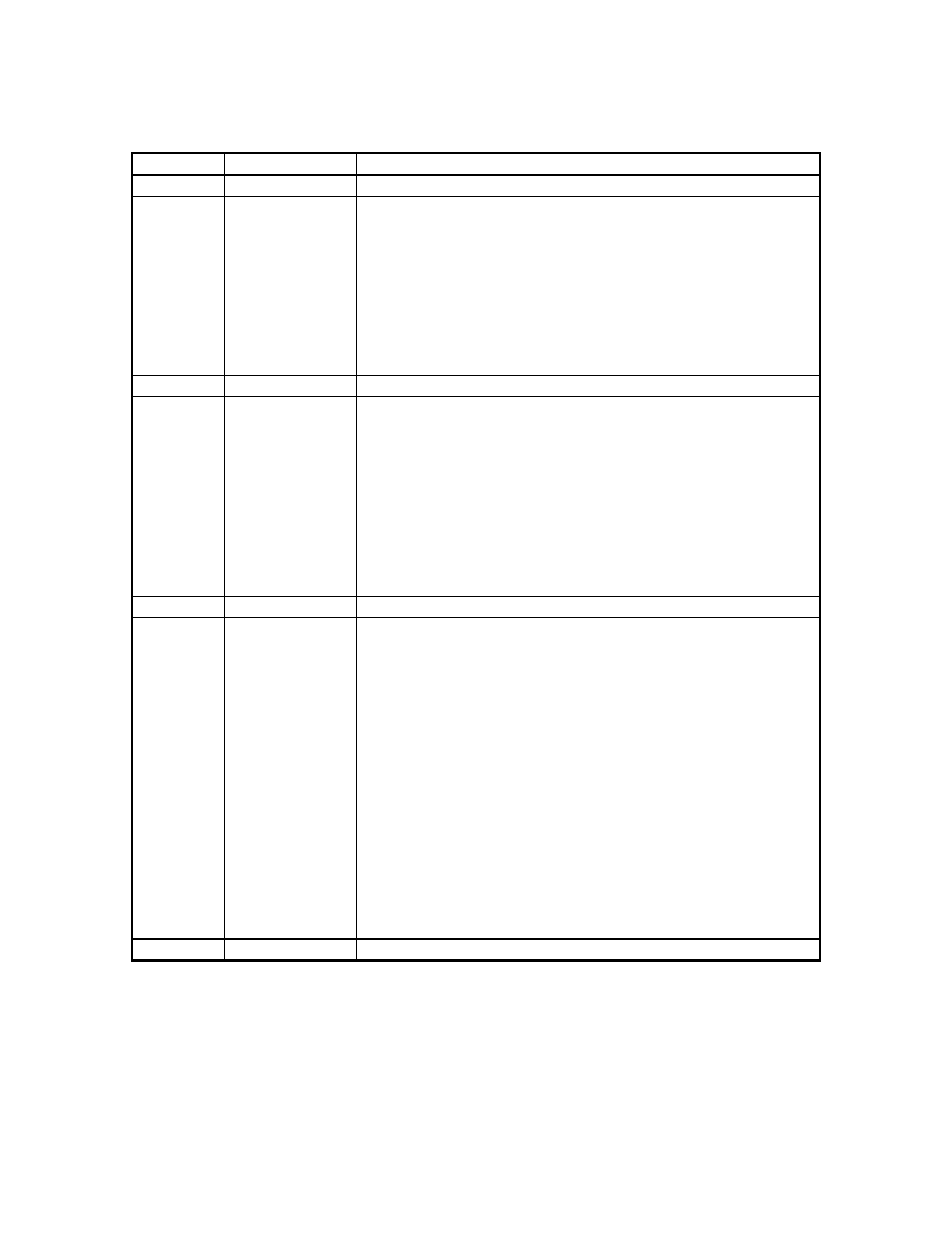

The following table shows the register areas defined in the 6500:

Address Read/Write

Description

1-128

Unused

129-143 Read/Write

Parameter type

The PLC must write to this area to tell the 6500 what

parameters it wants. Up to 15 parameters can be written here.

After the last parameter the PLC must write a “0”. For

example to instruct the 6500 to provide depth in feet followed

by temp in C the following should be written:

129: 23 (code for depth in feet)

130: 1 (code for temp in C)

131: 0 (tells the 6500 that this is the end of the list)

144-256

Unused

257-271 Read

only

Parameter status

The PLC can read back the values in these registers to check

the status of the parameters. The value in register 257

corresponds to the parameter type in register 129 and so on.

The meaning of the returned value is:

0 – The parameter is enabled in the sonde and actively

functioning.

1 – The parameter type is set to 0 (code for end of list).

2 – The parameter requested is not currently available in the

sonde.

272-384

Unused

385-414 Read

only

IEEE floating point parameter data

This is the actual parameter data in floating point form. Two

registers are used for each value to make up the 32 bits

required for a 4 byte IEEE floating point number. The value

in register pair 385:386 corresponds to the parameter type in

register 129 and so on.

It is highly recommended that this be used rather than the

scaled integer format. There several reasons for this:

• It’s easier to use since the numbers aren’t scaled. For

example a temp C value of 22.34 would be transmitted as

is, rather than as a converted value such as 7234.

• There is no implied range of values for a parameter.

Using scaled values forces a limit to the range of possible

values that a given parameter can take on.

• The maximum resolution of the data can be transferred.

415-640

Unused

YSI Incorporated

6500 Environmental Process Monitor

45