Modbus setup menu, 2 quality assurance – YSI 6500 Environmental Process Monitor User Manual

Page 50

Proper Use and Care of the 6500

Section 5

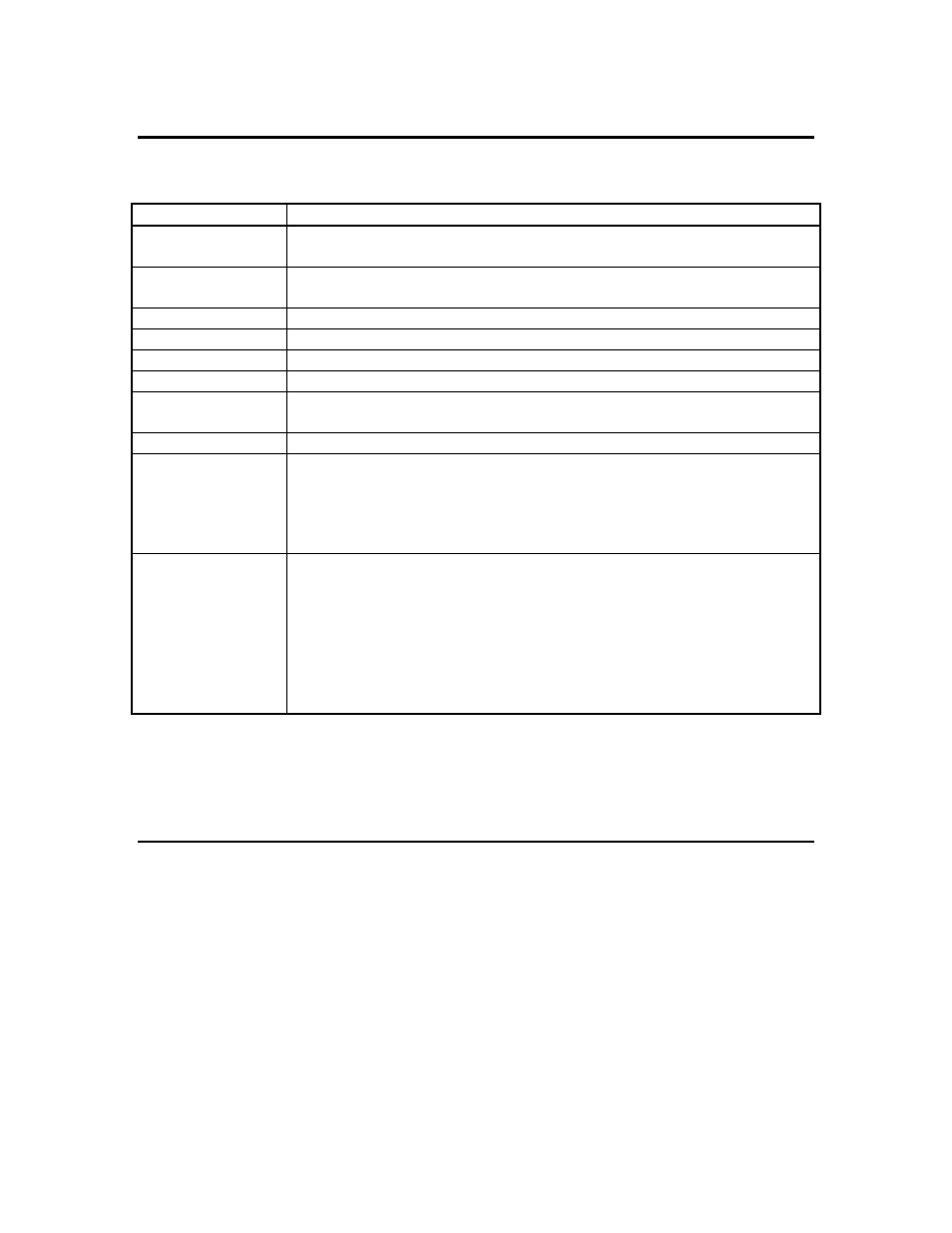

MODBUS SETUP MENU

This menu is accessed from the main menu under “Modbus setup”.

Menu item

Item description

Enable Modbus

This item must be “checked” to enable Modbus.

Note: this item must be off in order to update the code on a 6500.

Address

The effective Modbus address is the value you set here plus the sonde

address.

Hardware

Select from RS232 or RS485

Format

Select from ASCII or RTU

Baud rate

Select from 300, 600, 1200, 2400, 4800, 9600, and 19200

Data bits

Select from 7 or 8. Note that in RTU mode you must select 8.

Stop bits

Select from 1 or 2. This only affects the data transmitted from the 6500.

Data sent to the 6500 from the PLC can be 1 or 2 stop bits.

Parity

Select from None, Odd or Even.

Valid Messages

Displays the number of correctly formatted Modbus messages the 6500 has

received. This value increments to 65535 then rolls back to 0. This item

has been put here to help in troubleshooting problems. If the PLC and the

6500 are setup correctly you should see this number increment every time

the PLC talks to the 6500.

Param peek

Brings you to a menu that shows the values set in the Parameter Type area.

The values shown are not the integer value written, but rather the 6500’s

translation into a real label. For example if the PLC wrote as above the

values 23,1, and 0 then this menu would show the 2 items feet and temp C.

This menu is provided to give you some feedback that you have correctly

set the values in the Parameter Type area. All possible sonde addresses are

shown, even if they are not on line. You can navigate to each by pressing

the left and right arrow keys.

Please note that setup and calibration of sondes cannot be done through a Modbus interface. This

sonde interaction must be performed through a direct ‘6500 to sonde’ interface.

5.2 QUALITY ASSURANCE

Whatever method you choose to use with the 6500 monitor system, it is important to remember

that the quality of data with regard to your stream will be heavily dependent on three factors

directly related to the 6-Series Sonde:

9 Proper attention to detail of and general maintenance at the physical deployment site of your

sonde.

9 A well-defined quality assurance program that is carried out on a regular basis to assure that the

6-Series Sonde sensors are performing properly.

9 Proper periodic calibration and maintenance of the specific sensors within the 6-Series Sonde.

YSI Incorporated

6500 Environmental Process Monitor

47